Waste plastic oil refining to diesel plant

Waste Oil Distillation Plant / Date:04-01-2017

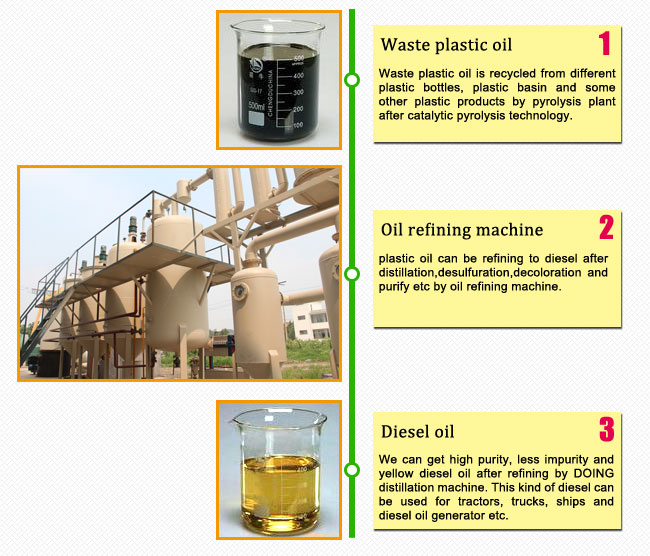

Waste plastic

Waste plastic to fuel oil

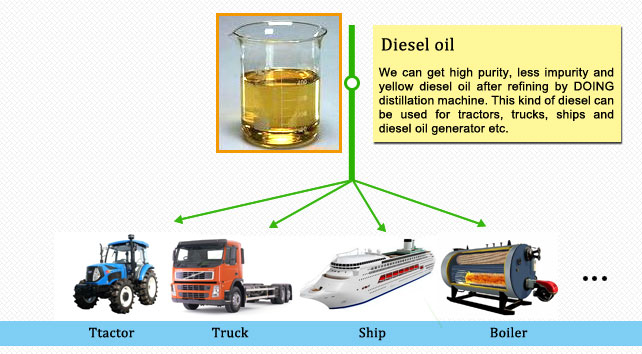

Generally speaking, the oil recovery rate is about 90%. The diesel oil or gasoline we finally get has clean and transparent color and qualified smell. This kind of diesel oil or gasoline can be widely applied in engines and generators and will produce less smoke and less noise than regular diesel fuel.

Waste plastic oil refining to diesel plant

We use green technology (pyrolysis and distillation) to recycle waste to oil resources. We use the pyrolysis technology to get crude oil from waste plastic, and then refine the crude oil into diesel oil with the distillation technology, which could better solve the oil resources decreasing problem while disposing of the waste.

| Technical parameter of waste plastic oil refining to diesel plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | Waste engine oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Waste plastic oil refining to diesel plant diesel application

Diesel oil application

Advantage of our distillation machineSafety is the most important factor in the whole process. We had successfully researched some safety devices which ensure the machine can work safely. Such as, the safety valves, alarming device and the pressure gauge etc.