Waste rubber to oil refine to diesel machine

Waste Oil Distillation Plant / Date:04-01-2017

Waste rubber pyrolysis plant

We obtain rubber oil from waste rubber through waste rubber pyrolysis plant. In order to make the rubber have more extensive applications, higher prices and higher values, now we have the latest waste rubber to oil refine to diesel machinefor sale to further process the rubber oil.

Waste rubber to oil refine to diesel machine

Rubber to oil refine to diesel machine

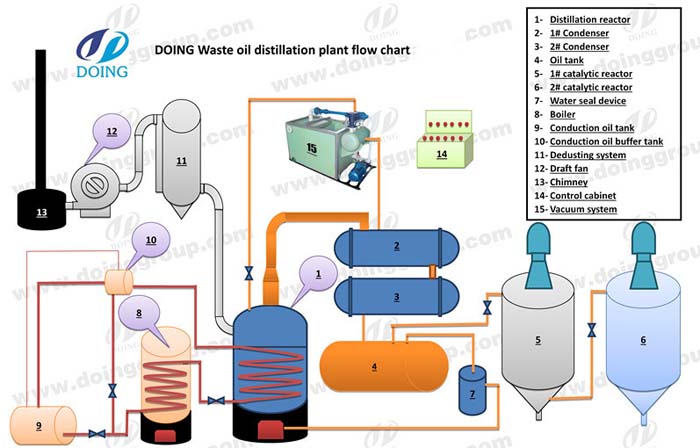

Waste rubber to oil refine to diesel machine working process

Rubber to oil refine to diesel machine working process

First of all, put the rubber oil in the waste rubber to oil refine to diesel tfor further process;

Secondly, heat the rubber oil in non-oxygen environment, which will start to boil and evaporate;

Thirdly, put those vapors through a cooling pipe and the vapors will be condensed to liquid and some of the vapors with shorter hydrocarbon lengths will remain as a gas;

Fourthly, the exit of the cooling pipe is then going through a bubbler containing water to capture the last liquid forms of fuel and leave only gas that is then burned;

Finally, this kind of oil will be piped into deep purifying system with acidity and alkaline cleaning device as well as pressure filtering system. And then, we can get qualified diesel fuel.

Rubber to oil refine to diesel machine advantage

Secondly, heat the rubber oil in non-oxygen environment, which will start to boil and evaporate;

Thirdly, put those vapors through a cooling pipe and the vapors will be condensed to liquid and some of the vapors with shorter hydrocarbon lengths will remain as a gas;

Fourthly, the exit of the cooling pipe is then going through a bubbler containing water to capture the last liquid forms of fuel and leave only gas that is then burned;

Finally, this kind of oil will be piped into deep purifying system with acidity and alkaline cleaning device as well as pressure filtering system. And then, we can get qualified diesel fuel.

Rubber to oil refine to diesel machine advantage

Rubber to oil refine to diesel machine

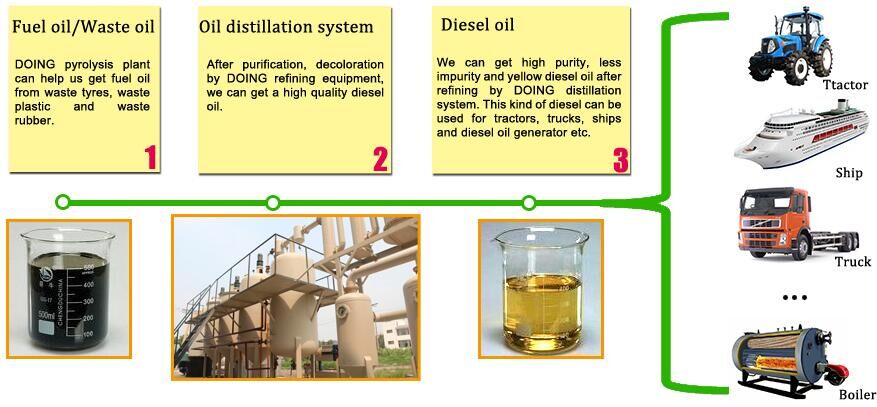

2.Can refine 3 kinds of oil--waste rubber oil, plastic oil and waste motor oil.

3.The final oil can be directly used for diesel oil generator, trucks and vans, etc.

4.Indirect heating by boiler heating system can greatly increase the service life of our waste rubber waste oil refining to diesel fuel machine.

5.Three steps purifying process ensure final diesel pure and high quality

| Technical parameter of waste rubber to oil refine to diesel machine | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Waste rubber to oil refine to diesel machine final product application

Diesel application of waste rubber to oil refine to diesel machine