Plastic to diesel converter plant

Waste Oil Distillation Plant / Date:09-30-2017

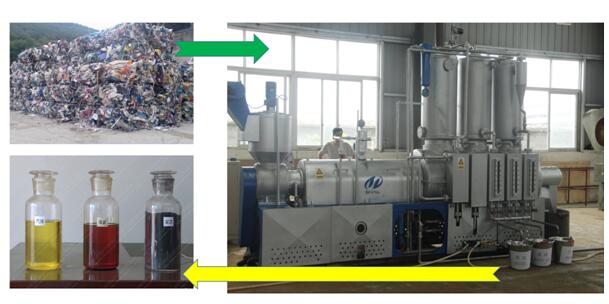

Plastic to diesel converter plant

Plastic to diesel converter plant

Plastic to diesel converter plant raw material

Plastic to diesel converter plant raw material

PET (Polyethylene Terephthalate).

Examples: Soft drinks bottles, food grade packaging and trays.

PVC (Polyvinyl Chloride). Examples: Pipes, window fittings, bottle s and laminates.

Other Examples: Foams, nylons and fiberglass

Plastic to diesel converter plant working process

Plastic to diesel converter plant

It needs the input materials shredded or crushed into small pieces less than 3-5cm for automatic and continuous feeding;

2) Preheating to remove Dioxin

As we all know that Dioxin is very easy to be produced from many kinds of waste burning process, especially chlorine substance, like PVC plastics, paper-mill waste, household garbage, etc. And the emission of Dioxin will cause serious problems to the environment and human body, thus it need to be seriously disposed and removed before released to the air.

3) Pyrolysis

After remove the Dioxin, the input materials will go to the pyrolysis reactor for further heating and cracked to oil gas.

4) Catalysis

5) Distillation

6) Fractionation

7) Extra gas recycling and collection

8) Carbon black slagging

Plastic to diesel converter plant feature

Plastic to diesel converter plant

1:The whole process will be controlled by PLC, with a highly automatic operation.

2:Environmental-friendly, the whole process has no pollution

3: With sterilization system, our machine can efficiently recycle used medical plastics waste into treasure with a big commercial value.

Final product of Plastic to diesel converter plant

We can get petrol ,gas and carbon black

2) Gasoline

3) Heavy oil

4) Carbon black