Waste engine oil to diesel machine

Waste Oil Distillation Plant / Date:10-25-2018

People dispose of engine oil from their cars; truck and motor without knowing that they can be recycled to produce high-quality clean oil that can be re-used again in their vehicles and ships. The waste engine oil to diesel machine uses the most advanced technology to produce clean oil that can be used again and it doesn’t cause secondary pollution to the environment.

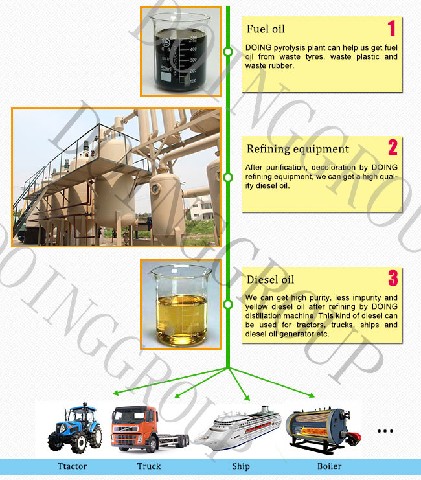

Waste engine oil to diesel machine is also called oil refining machine. It can refining waste oil(waste engine oil,motor oil, tyre oil, plastic oil etc) to clean diesel. The oil recovery yield is about 85% ( according to oil quality).

Waste engine oil to diesel machine

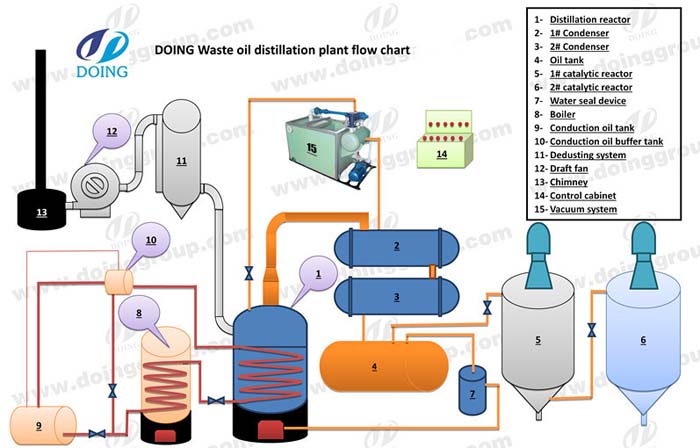

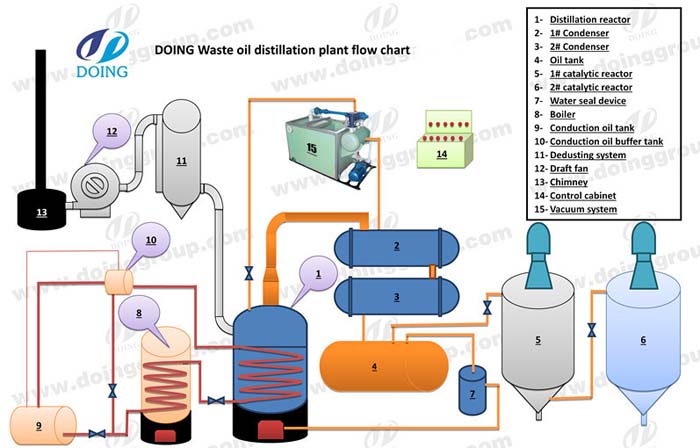

Feed liquid wasteoil - heating - catalytic cracking - cracking - fractionation - cooling liquid- decompression - flammable gas recovery - flammable gas combustion -desulfurization

Check here to know waste engine oil to diesel machine project

After-sale Service:

1.Design the installation drawings according to your site

2.For each set of waste engine oil to diesel machine, one engineer will be sent toguide your installation, test the machine and train your workers.

3.1 year warranty, engineers available to service at any time

4.Periodical call visit, to make sure there is no problem of the equipment

5.Design specific maintenance program according to different situation of yourplant

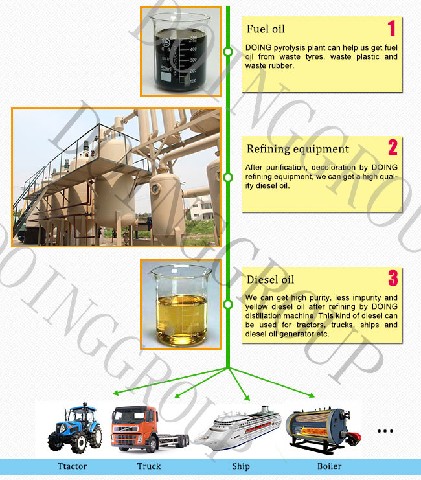

Diesel oil Usage:

The diesel oil obtained can be widely used in more kinds of diesel engines and will produce less smoke and less noise than regular diesel fuel. In addition to producing products that have high economic values, our waste engine oil to diesel machine also have the features of safe, energy saving and environment friendly.

Diesel oil usage

Waste engine oil to diesel machine is also called oil refining machine. It can refining waste oil(waste engine oil,motor oil, tyre oil, plastic oil etc) to clean diesel. The oil recovery yield is about 85% ( according to oil quality).

Waste engine oil to diesel machine

Waste engine oil to diesel machine working process:

Waste engine oil to diesel machine

Check here to know waste engine oil to diesel machine project

After-sale Service:

1.Design the installation drawings according to your site

2.For each set of waste engine oil to diesel machine, one engineer will be sent toguide your installation, test the machine and train your workers.

3.1 year warranty, engineers available to service at any time

4.Periodical call visit, to make sure there is no problem of the equipment

5.Design specific maintenance program according to different situation of yourplant

| Technical parameter of waste engine oil to diesel machine | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Diesel oil Usage:

The diesel oil obtained can be widely used in more kinds of diesel engines and will produce less smoke and less noise than regular diesel fuel. In addition to producing products that have high economic values, our waste engine oil to diesel machine also have the features of safe, energy saving and environment friendly.

Diesel oil usage