6/8/10T capacity waste tyre pyrolysis plant for sale

Waste tyre for treatment and recycling

Waste tyre for treatment and recycling

With the fast development of society, the amount of waste tyres is larger and larger. In recent years, the tyre pyrolysis technology has also been developed. Conventional waste tire treatment and recycling methods are discarding, landfilling, incineration, or retreading and making devulcanized rubber or rubber powder. While traditional methods like producing devulcanized rubber consume excessive energy and cause pollution, pyrolysis technology offers a more efficient and eco-friendly alternative.

Doing waste tyre pyrolysis plant for sale

Doing waste tyre pyrolysis plant for sale

As a world-leading reliable pyrolysis plant manufacturer and supplier, Henan Doing Company is proud to present our best-selling model, the 6/8/10/15T capacity waste tyre pyrolysis plant, renowned for its cost-effectiveness, substantial profitability, and wide popularity among customers.

Our waste tyre pyrolysis plant is designed to convert waste tyres into valuable renewable resources, including pyrolysis oil, carbon black, steel wire, and combustible gas. Our plant utilizes the latest pyrolysis technology, making it suitable for various applications such as oil sludge treatment, waste plastic pyrolysis, and rubber tyre material treatment, coal tar disposal, aluminum plastic recycling, etc.

Solid wastes raw materials for pyrolysis plant

Solid wastes raw materials for pyrolysis plant

Waste tyre pyrolysis plant is an environmental protection system which uses the continuous liquefaction technology and catalytic breakdown reaction to convert waste tyre into renewable resources, such as pyrolysis oil,carbon black,steel wire combustible gas and so on.

DY-6T capacity waste tyre pyrolysis plant (D2200mm*L6000mm)

1. This mode of pyrolysis plant can load 6 tons of crushed tires or whole tires per batch.

2. Equipped with an auto-feeder, our plant eliminates the need to wait for the pyrolysis machine to cool down before feeding more materials. This not only saves time but also enhances safety.

3. Built-in spiral plates ensure the smooth and even-speed movement of waste tyres throughout the process. This can ensure that the waste tires are fully pyrolyzed.

DY-8T capacity waste tyre pyrolysis plant (D2200mm*L6600mm)

1. It can load 8 tons of waste tyres.

2. The reactor adopts Q245R/345R steel, industrial boiler plate or stainless steel plant and its thickness is 14/16/18/20mm, which can bear high temperature and high pressure.

3. The reactor has an all-inclusive four layers, the outer external thermal insulation layer built-in cotton insulation, fire cement, steel hook and steel plate, which can avoid heat loss and save energy consumption.

DY-10T capacity waste tyre pyrolysis plant (D2600mm*L6600mm)

1. Working with Auto-feeder, it is able to contain 12 tons crushed tires or 10 tons whole tires.

2. For plastic, it can contain even 12 tons.

3. The diameter of feeding port is 1200mm or 1400mm.

After 2 hours feeding time, it's time to heat the reactor with coal/wood/natural gas/crude oil. Generally speaking, when the temperature is up to about 155 Celsius degrees, the oil gas will generate.

Waste tyre working time you may need:

Let's take 10 tons waste tires that processed by DOING waste tyre pyrolysis plant as an example:

| Model | Feeding | Processing | Cooling | Discharge | Total |

| 2200*6000 | 1.5hr | 7-8hr | 1.5hr | 1.5hr | 12hr |

| 2200*6600 | 1.5hr | 8hr | 1.5-2hr | 1.5hr | 14hr |

| 2600*6600 | 2 hr | 10 hr | 2-3 hr | 2-3 hr | 16-18 hr |

With Henan Doing Company's 6/8/10T capacity waste tyre pyrolysis plant, you can effectively convert waste tyres into valuable resources while mitigating environmental impact. Our high-performance and customizable solutions ensure both cost-efficiency and substantial profits.

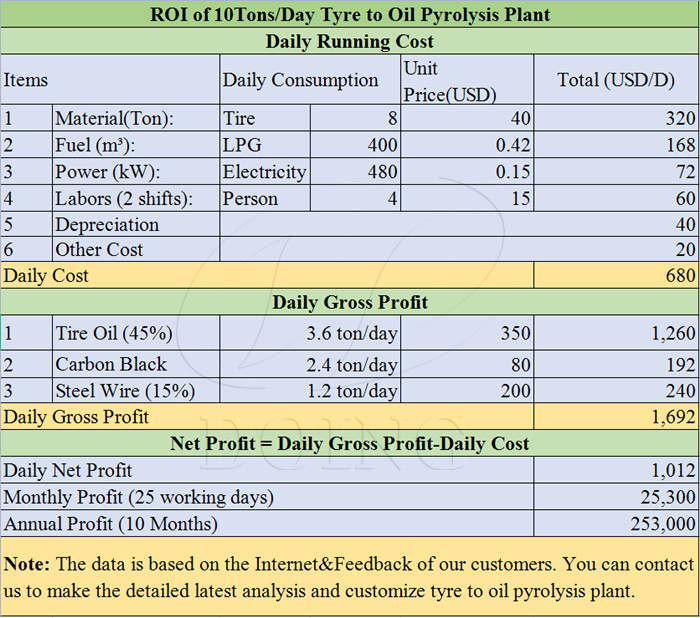

10 ton waste tyre pyrolysis plant profit analysis

10 ton waste tyre pyrolysis plant profit analysis

Besides the popular-sale 6/8/10T capacity waste tyre pyrolysis plant for sale, we also provide other batch/semi-continuous/fully continuous waste tyre pyrolysis plant for sale from small 100KG Skid-mounted types to big industrial 50T waste tyre pyrolysis plant. Contact us now to explore our customized options tailored to meet your specific requirements at factory price!

6/8/10T capacity waste tyre pyrolysis plant for sale technical data

| Technical parameter of 6/8/10T capacity waste tyre pyrolysis plant for sale | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyre | Waste tyre | Waste tyre |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about 6/8/10T capacity waste tyre pyrolysis plant | ||

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |

6/8/10T capacity waste tyre pyrolysis plant final product application

Fuel oil (40% to 45%)

Tyre pyrolysis fuel oil applications and usages

Tyre pyrolysis fuel oil applications and usages

The main oil product produced by waste tyre pyrolysis recycling plant is the fuel oil that is wide used for industrial and commercial purposes, such as heating boilers, furnaces of brick factories, cement factories, glass plants, steel plants, or heavy oil power plants. You can also refine the pyrolysis oil into diesel by waste oil distillation plants for further uses. The oil accounts for 40% to 45% of the products of recycled scrap tyres, which will be carried with licensed tanker trucks.

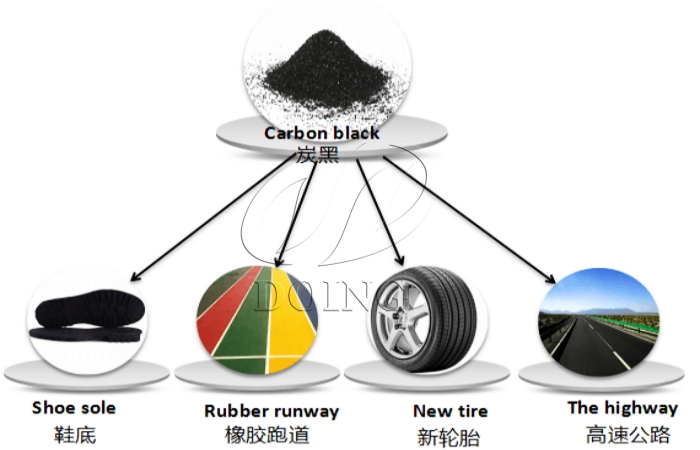

Carbon Black (30% to 35%)

Tyre pyrolysis carbon black application

Tyre pyrolysis carbon black application

Carbon Black is the main product recycled by pyrolysis technology. The amount of recycled carbon black is 30% to 35% (depending on the type of tyres) of the total amount of scrap tyres recycled in the system. Carbon black is used as raw material or main ingredient in many industries and the chemical structure of carbon black strengthens, lengthens the endurance, and improves the coloring features of the materials.

Carbon black produced by Pyrolysis process (CBp) is more economical compared to carbon black produced primarily from petroleum and is more price-efficient to be used as an ingredient in the industries listed;

* Electric cable jacketing

* Conveyor band

* Carrier Bands

* Hose and doormat

* Black nylon bag

* Rubber additive

* Automotive spare parts

* Heat isolation

* Black colorant in rubber materials

* Plastic pipes

* Industrial rubber products

* Fire fighting

Steel wire (10% to 15%)

Tyres contain steel wires and the amount range of 10% to 15% of the total tyre wastage. All of the steel present in the tyre can be detached after pyrolysis recycling process in completed. Valuable steel wires are pressed and sold to steel and scrap dealers.

Gas (10% to 12%)

Non-Condensable gases arise during the tyre to oil recycling process.

Some advantages such as…..

* It has higher calorific value as compared to Natural Gas.

* It can be replaced where Natural Gas and Propane are stored.

* The high energy gas may be utilized as a source of energy for the Pyrolysis process.

* The amount of gas generated in the system is 12% to 15% of the total amount of recycled tyres and considering the 10 ton scrap tyre/day recycling capacity, the facility generates 1200-1500 m3/day gas, which has an enormous energy potential when evaluated.

Request Information

Send your inquiry for further information