Waste tire oil pyrolysis plant to fuel oil

Waste tire oil pyrolysis plant to fuel oil

The scientists and the far sighted manufacturers recommend the Waste tire oil pyrolysis plant to fuel oil, which adopts the pyrolysis technology.

Waste tire oil pyrolysis plant to fuel oil

What is pyrolysis:

Pyro = heat. Lysis = break down.

Pyrolysis is chemical reaction. This reaction involves molecular breakdown of larger molecules into smaller molecules in presence of heat. Pyrolysis is also known as thermal cracking, cracking, thermolysis, depolymerization, etc.

Tire pyrolysis is: the process of converting waste tires into industrial fuels like Tire Pyrolysis Oil, Carbon Black, Steel Wire and Hydrocarbon Gas.

Tire pyrolysis involves subjecting tire to high temperature of 400 to 450 degree Celsius, in absence of oxygen. In case of oxygen is present plastic will start burning. During pyrolysis tire breaks down into smaller molecules of pyrolysis oil, pyrolysis gas, steel wire and carbon black. Pyrolysis is a great way of recycling large amounts of tires. This waste tire oil pyrolysis plant to fuel oil can also used for waste plastic recycling.

Oil yield of different waste tire/rubbers:

| Raw material | Oil yield |

| Submarine cable | 75% |

| Rubber cable | 35% |

| Sole | 30% |

| Big tires | 45%-50% |

| Small tires | 35%-40% |

Waste tire oil pyrolysis plant to fuel oil technical data

| Technical parameter of Waste tire oil pyrolysis plant to fuel oil | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tires | Waste tires | Waste tires |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about waste tire oil pyrolysis plant to fuel oil | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

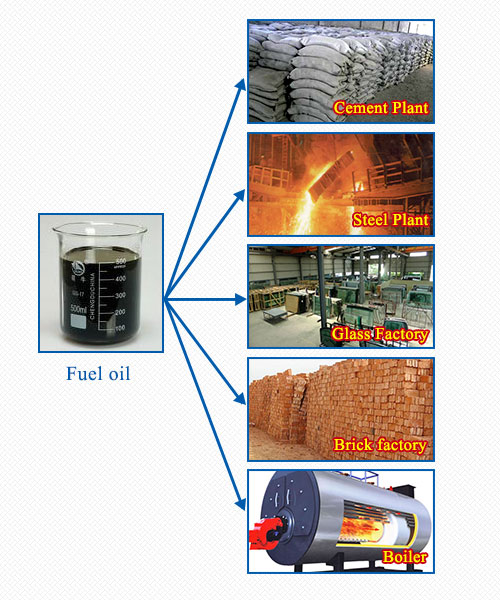

Waste tire oil pyrolysis plant to fuel oil final product application

Waste tire oil pyrolysis plant to fuel oilfinal product application

Carbon black application

| Items | Application | Sales Market |

| 45% tire oil | 1. Add it into heavy oil generator to produce electricity. 2. Used as heating material. 3. Sell it into oil refining factory to further process it | Ceramic factory, glass factory, electric power factory, steel making factory, boiler factory…etc. |

| 30% Carbon black |

1. Deep process it into Carbon black. 2. Make it into pellet or briquette for burning. 3. Further process it into color master batch as basic material to make pipes, cable jacket…etc. |

Coal briquette factory, plastic factory, cable factory, etc. |

| 15% Steel wire(for tire) | Sell it directly | Iron and steel factory |

| 10% Waste gas | Recycled into fire furnace to heat reactor to save fuel material. |

Request Information

Send your inquiry for further information