Waste plastic to fuel oil pyrolysis plant

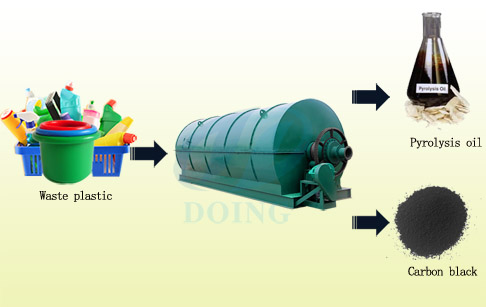

Doing group produced waste plastic to fuel oil pyrolysis plant with lower cost and higher fuel oil output can convert waste plastic to fuel oil ,carbon black .

Waste plastic to fuel oil pyrolysis plant

Pyro = heat. Lysis = break down.

Pyrolysis is chemical reaction. This reaction involves molecular breakdown of larger molecules into smaller molecules in presence of heat. Pyrolysis is also known as thermal cracking, cracking, thermolysis, depolymerization, etc.

Waste plastic to fuel oil pyrolysis plant working process

During pyrolysis plastic breaks down into smaller molecules of pyrolysis oil, pyrolysis gas and carbon black. Pyrolysis is great a way of recycling waste plastics. This waste plastic to fuel oil pyrolysis plant can also used for waste tire recycling.

Waste plastic to fuel oil pyrolysis plant feature

Adopt multilevel cooling circulation to get more fuel oil.

2. Discharge process through pulse dust removal processing, no dust emissions.

3. Easy operation, high efficiency and 2-3 people to operate.

4.Waste plastic to fuel oil pyrolysis plant adopts fully automatic submerged arc welding process, through x-ray detection, to improve the security of plant.

Waste plastic to fuel oil pyrolysis plant technical data

| Technical parameter of Waste plastic to fuel oil pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about Waste plastic to fuel oil pyrolysis plant | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

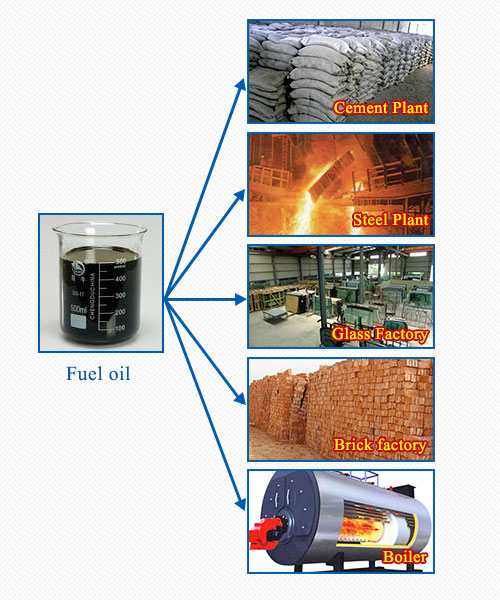

Waste plastic to fuel oil pyrolysis plant final application

Waste plastic to fuel oil pyrolysis plant final application

A.power plant factory

B.glass factory

C.cement factory

D.ceramic fatory

E.aluminum factory

F.boiler factory

G.central heating factory

H.painting factory

1.A. Waste plastics, Used bottles,used tyres, used bags, farming waste , other

B.Medical waste

C.oil sludge , waste oil ,black oil ,oily solid

D.other living waste

Request Information

Send your inquiry for further information