Waste rubber to oil recycling process machine

In the modern days, waste rubbers are serious issues for many countries. More wastes mean more pollution. In the times that almost all people are seeking for the “Green” life style, machines to dispose various kinds of wastes are certainly warmly welcomed. Therefore, many waste plastic/tyre/rubber to oil pyrolysis plant suppliers have come to the world. However, Doinggroup is always in the leading position in the pyrolysis plant industry. Waste rubber to oil recycling process machine adopts the main technology: pyrolysis. Pyrolysis is a chemical reaction that involves molecular cracking from larger molecules to smaller ones with the support of heating in the high temperature.

Waste rubber to oil recycling process machine

Our waste rubber to oil recycling process machine are aimed to make useful renewable resources out of wastes, such as fuel oil, carbon clack, and fuel gas, etc. Meanwhile, we are dedicated to realize no pollutant emissions during the whole process. Thereby, we can reach a true meaning of environmental protection Enterprise.

Our waste rubber to oil recycling process machine can convert waste rubber into high grade diesel fuel and carbon black . Waste rubber are long chain polymers containing more than 50000 carbon atoms attached to each other in a cross linked or straight chain.During waste rubber pyrolysis, this long chain is broken down into smaller chain. The Waste rubber to oil recycling process machine turns waste materials into gases and liquids. The end products can be used in any standard diesel engine or generator with little or no modifications.

Waste rubber to oil recycling process machine working process

Waste rubber to oil recycling process machine working process

1.Feed raw materials

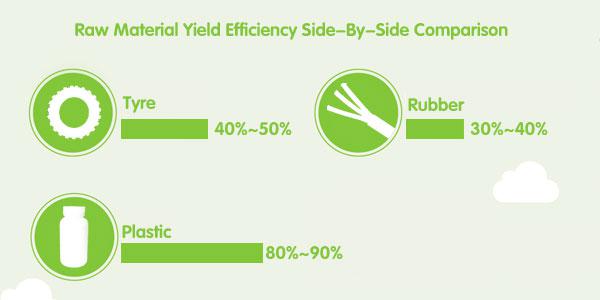

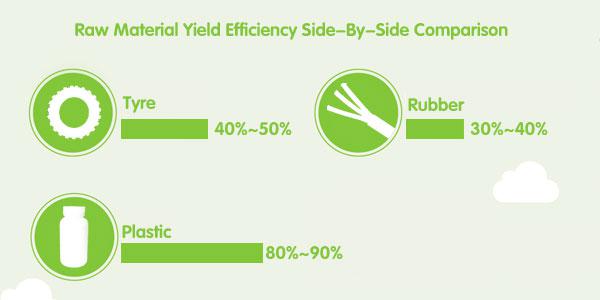

The raw material can be waste tire/waste plastic/waste rubber. Always feed by the auto feeder.

2.Pyrolysis

Include a reactor and catalyst room. Heat the reactor by coal/wood/oil/natural gas. This part will produce high temperature oil gas, the oil gas then flow into the next system.

3. Condensing

Oil gas come out from the reactor and catalyst chamber then cooling down in this part. Condensing system include condenser pipe, oil water separator, horizontal condenser and waste gas condenser. This will make the oil yield to the maximum.

4.Waste gas recovery

This part mainly deal with the gas that cannot be condensed. The whole process is very steady and high efficiency.

5. Discharge

After finished oil produce, the temperature of reactor can be cooled down, When the temperature falls down to 40 degree then carbon black can be discharged automatically by the way of anticlockwise rotate the reactor. The carbon black will drop into slag pool and then use screw conveyor to clean the slag pool. After discharging the carbon black.

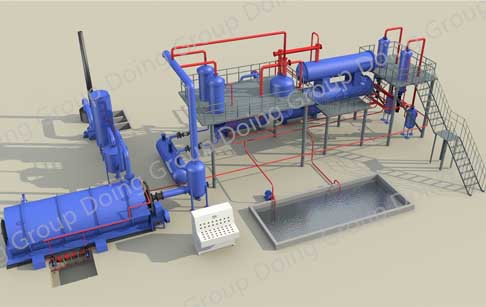

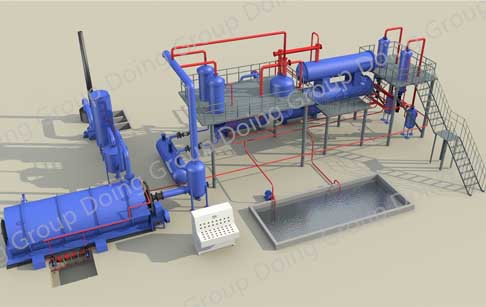

Waste rubber to oil recycling process machine advantage

3 D picture of Waste rubber to oil recycling process machine

1. Safety.

We have some safe devices such as the pressure gauge, alarming ring, safety valve. at the same time we have the anti-back fire device which can avoid the fire back into the reactor.

2. Environment protecting.

If you come to visit our company to see the running plant, you cannot even see the vapor. as we have the dust removal device and dust removal pool.

3. Energy saving.

Our anti-back fire device can collect the exhaust gases which can be fuels after the oil is out so is very convenient and you can save the energy .at the same time, we have the catalyst

chamber which can reduce the temperature of the catalytic prolysis of the tires and plastics. so you can save lot's of energy. except this ,we have vacuum device which let the reactor be negative pressure. So you can image.

4. High degree of automatic.

We have many automatically devices such as: auto-feeder, carbon black elevator, oil pumping automatic, reducing pressure automatic.

Waste rubber to oil recycling process machine working process technical data

Fuel oil: Widely used as fuel oil in industries such as steel and iron factories, ceramics or chemical industries or hotels, restaurants etc. or used for generators to get electricity.

Fuel oil application

Carbon black: used for construction bricks with clay also can be used as fuel

Combustible gas: Can be recycled and used during process as fuel.

Waste rubber to oil recycling process machine

Our waste rubber to oil recycling process machine can convert waste rubber into high grade diesel fuel and carbon black . Waste rubber are long chain polymers containing more than 50000 carbon atoms attached to each other in a cross linked or straight chain.During waste rubber pyrolysis, this long chain is broken down into smaller chain. The Waste rubber to oil recycling process machine turns waste materials into gases and liquids. The end products can be used in any standard diesel engine or generator with little or no modifications.

Waste rubber to oil recycling process machine working process

Waste rubber to oil recycling process machine working process

The raw material can be waste tire/waste plastic/waste rubber. Always feed by the auto feeder.

2.Pyrolysis

Include a reactor and catalyst room. Heat the reactor by coal/wood/oil/natural gas. This part will produce high temperature oil gas, the oil gas then flow into the next system.

3. Condensing

Oil gas come out from the reactor and catalyst chamber then cooling down in this part. Condensing system include condenser pipe, oil water separator, horizontal condenser and waste gas condenser. This will make the oil yield to the maximum.

4.Waste gas recovery

This part mainly deal with the gas that cannot be condensed. The whole process is very steady and high efficiency.

5. Discharge

After finished oil produce, the temperature of reactor can be cooled down, When the temperature falls down to 40 degree then carbon black can be discharged automatically by the way of anticlockwise rotate the reactor. The carbon black will drop into slag pool and then use screw conveyor to clean the slag pool. After discharging the carbon black.

Waste rubber to oil recycling process machine advantage

3 D picture of Waste rubber to oil recycling process machine

We have some safe devices such as the pressure gauge, alarming ring, safety valve. at the same time we have the anti-back fire device which can avoid the fire back into the reactor.

2. Environment protecting.

If you come to visit our company to see the running plant, you cannot even see the vapor. as we have the dust removal device and dust removal pool.

3. Energy saving.

Our anti-back fire device can collect the exhaust gases which can be fuels after the oil is out so is very convenient and you can save the energy .at the same time, we have the catalyst

chamber which can reduce the temperature of the catalytic prolysis of the tires and plastics. so you can save lot's of energy. except this ,we have vacuum device which let the reactor be negative pressure. So you can image.

4. High degree of automatic.

We have many automatically devices such as: auto-feeder, carbon black elevator, oil pumping automatic, reducing pressure automatic.

Waste rubber to oil recycling process machine working process technical data

| Technical parameter of waste rubber to oil recycling process machine working process | ||||

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste rubber | Waste rubber | Waste rubber |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

Waste rubber to oil recycling process machine working process final product application

Fuel oil: Widely used as fuel oil in industries such as steel and iron factories, ceramics or chemical industries or hotels, restaurants etc. or used for generators to get electricity.

Fuel oil application

Carbon black: used for construction bricks with clay also can be used as fuel

Combustible gas: Can be recycled and used during process as fuel.

Request Information

Send your inquiry for further information