Waste plastic recycling process plant cost

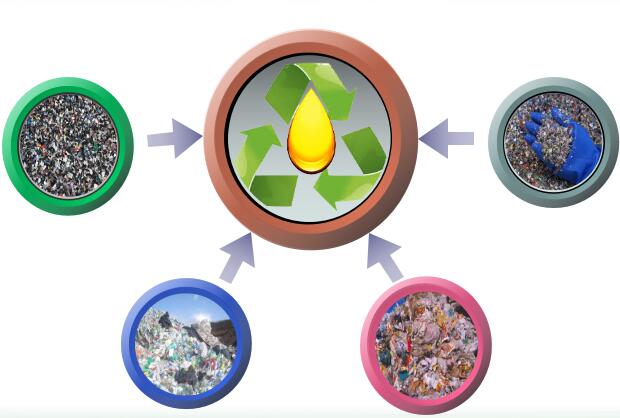

Waste plastic

Also because the waste plastic recycling process plant technologies are relatively simple, easy to master, intuitive and suitable for factories, collective and individual, the future of the industry appears extremely promising. Therefore, we can predicate that the reuse and recycle of the waste oil will be one of the new

industries with the most potential for development.

Waste plastic recycling process plant cost

We are one the best cost-effective waste plastic recycling process plant cost to fuel oil provide. It result in 100% wastage plastic

Waste plastic recycling process plant cost feature

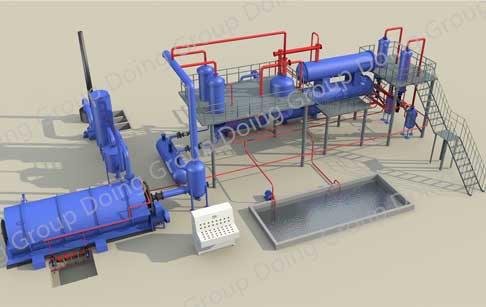

3D picture of waste plastic recycling process plant cost

1.There is no chum left after the process

2.No any chemical are used in plastic pyrolysis process therefore the waste plastic reycling process plant is environment friendly.

3.After the plastic reusing process no soil, water or air pollution is observed.

4.Very low budget wastage plastic pyrolysis technology in the world.

5.Waste plastic recycling process plant cost is technically feasible in terms of operation and maintenance Valuable Products – carbon black and plastic oil are obtained from waste plastic recycling process plant cost

6.Waste plastic recycling process plant cost process raw material is cheap and easily available

Approx oil yield rate of different raw material

PE/ldpe/hdpe 50%-75%

PP 50%-75%

PS 50%-75%

ABS 40%

Leftovers of paper Wet 15-20%, dry 60%

House garbage 35-50%

Plastic cable 80%

Plastic bag 50%

Submarine cable 75%

Rubber cable 35%

Sole 35%

PVC Not suitable

PET Not suitable

Waste plastic recycling process plant cost technical data

| Technical parameter of waste plastic recycling process plant cost | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about waste plastic recycling process plant cost | ||

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |

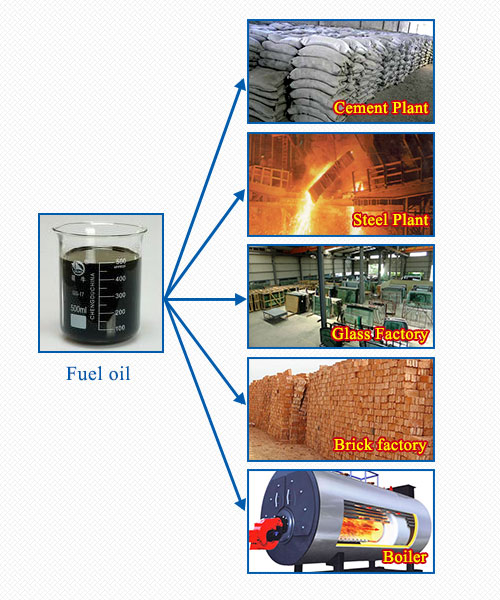

Waste plastic recycling process plant cost application

Fuel oil application

The main oil product produced by our waste recycling application is the fuel oil that is wide used for industrial and commercial purposes, which will be carried with licensed tanker trucks.

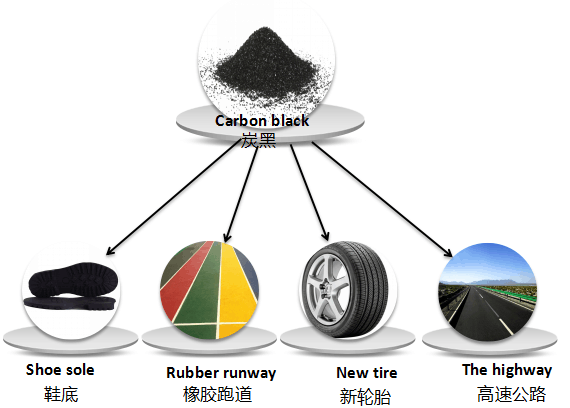

Carbon black application

Electric cable jacketing

Conveyor band

Carrier Bands

Hose and doormat

Black nylon bag

Rubber additive

Automotive spare parts

Heat isolation

Black colorant in rubber materials

Plastic pipe

Industrial rubber products

Fire fighting

Request Information

Send your inquiry for further information