Waste plastic recycling machine

Waste plastic

Waste plastic recycling machine

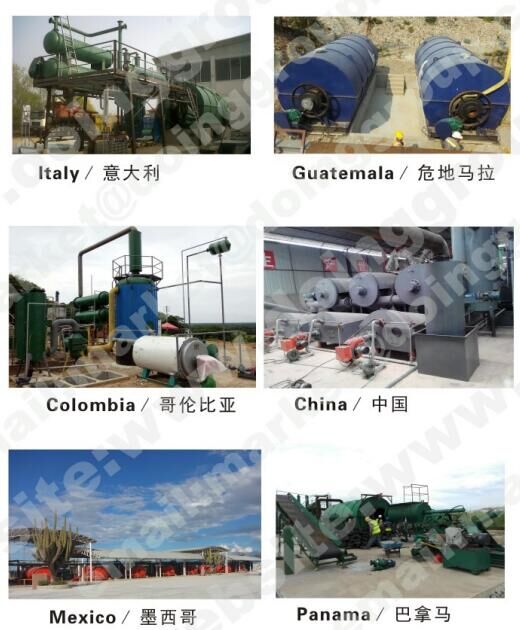

Till now, our plastic waste recycling machine has be exported to more than 30 countires, such as Egypt, Malaysia, Mexico, Italy, Romania, Ecuador, Haiti, Thailand etc.

If your country also faces with plastic pollution, welcome to contact us and get more information about our waste plastic recycling machine.

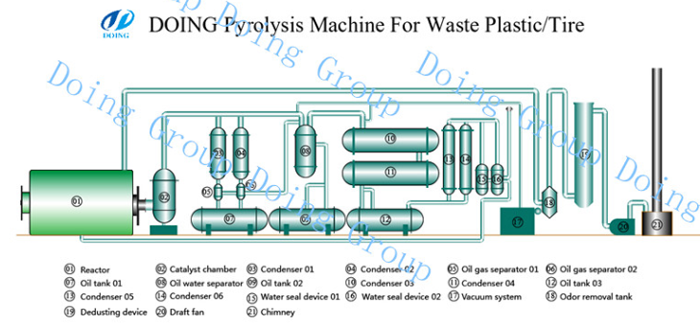

Waste Plastic recycling machine process

Waste plastic recycling machine

2.Secondly, burn the fuel material (coal, wood, oil or natural gas) in the combustion system. The reactor will slowly heat, when the temperature reach around 120℃, it will produce oil gas.

3.Thirdly, oil gas will be processed and then go to cooling system to cold liquid oil. The gas which can not be liquid under normal pressure will go back to combustion system to replace the fuel material to burn the reactor.

4.Fourthly, after finished oil production, the temperature of reactor will be down and the carbon black will be discharged automatically.

Waste plastic recycling machine feature

Waste plastic recycling machine installed in different countries

1. Reactor with auto welding to guarantee the quality of welding seam and avoid cracking

2. Professional heating treatment and x-ray detection chamber for welding seam.

3. Vacuum system to prevent oil gas be back to reactor causing accident.

4. with temperature meter, pressure meter and safety valve.

Environment friendly:

1. Dedusting system to prevent gas and dust from coal burning

2. The exhaust gas will be recycled for heating reactor, no gas pollution

3. Well sealing on every junction parts to prevent gas leak, no smelly

Longer life:

1.use Q245R special steel plate ,thickness 16mm. welding seam with auto welding and will get heating treatment and x-ray detection to extend the life of reactor to the most extend.

2. The life will be 6-8 years

Energy saving:

1. Well sealing for heating system, no gas leak and saving fuel.

3.Waste plastic recycling machine of Doing is convert waste plastic to oil .The raw material of conver plastic into oil machine is waste palstic ,waste tyres,waste rubber. Convert plastic into oil machine with high efficient and environmently friendly ,no pollution to air,waste and earth .

Waste plastic recycing machine technical data

| Technical parameter of Waste plastic recycling machine | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyre | Waste tyre | Waste tyre |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about Waste plastic recycling machine | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

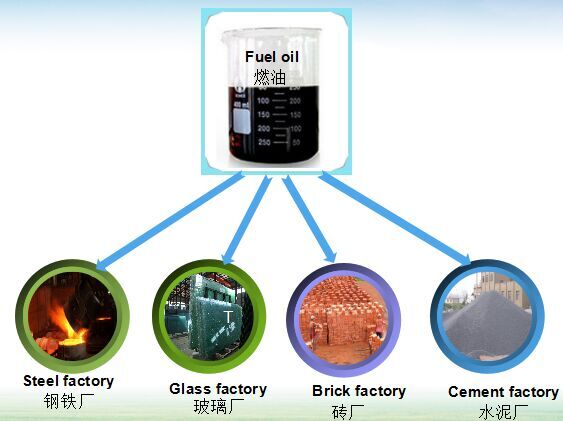

Fuel oil from waste plastic recycling machine used in below industries

Fuel oil application

B.Glass factory

C.Cement factory

D.Ceramic fatory

E.Aluminum factory

F.Boiler factory

G.Central heating factory

H.Painting factory

Carbon black application

A.Electric cable jacketing

B.Conveyor ban

C.Hose and doormat

D.Black nylon bag

E.Rubber additive

F.Automatic spare parts

G.Heat isolation

H.Black colorant in rubber materials

Request Information

Send your inquiry for further information