Plastic to oil

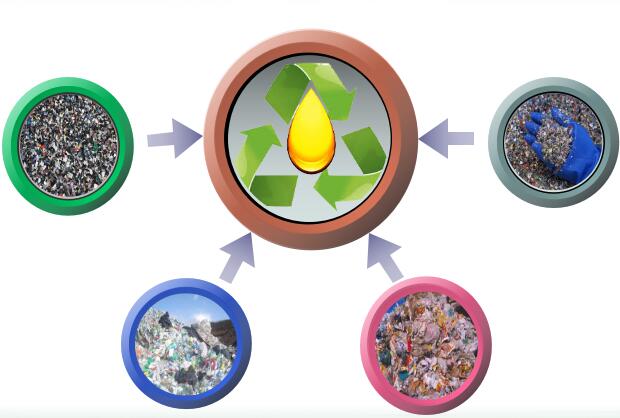

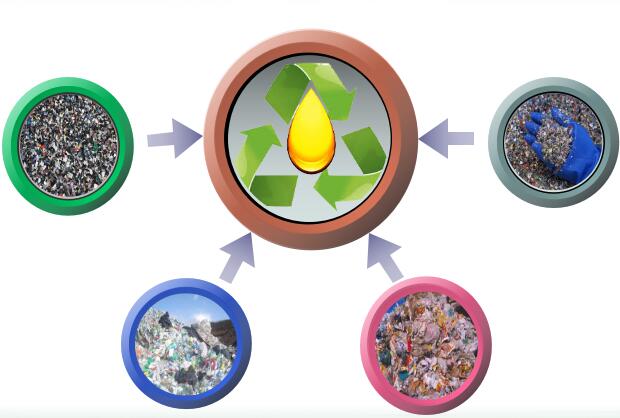

Plastic products has been used widely, and waste plastic can be seen everywhere. It has seriously affected our environment on two aspects, such as visual pollution and potential hazards. Visual pollution means that aesthetic perception on living city affected by scrap plastic in everywhere. Potential hazards mainly refers to degradation-resistant of waste plastic affecting on absorbing of nutrients and water by crop, reducing the production; and otherwise, animals will be die if eats it unconscious. Recycling and utilization of waste plastic is increasingly becoming an important aspect for environmental protection.

Pyrolysis of plastic to oil process machine

Pyrolysis of plastic to oil process machineis an environmental protection system which uses the continuous liquefaction technology and catalytic breakdown reaction to convert waste plastics into renewable resources, such as pyrolysis oil, carbon black, combustible gas and so on. The end products can be applied to diesel engines and generators directly, or come into high ranking diesel and gasoline through our oil refining plant. Other names of plastic pyrolysis plant: waste plastic pyrolysis machine, plastic to oil machine/plant, waste plastic to fuel conversion plant, plastic2oil plant and so on.

New product pyrolysis of plastic to oil process machine features

Pyrolysis of plastic to oil process machine

Our pyrolysis of plastic to oil process machine can convert waste plastic into high grade diesel fuel. Waste plastic are long chain polymers containing more than 50000 carbon atoms attached to each other in a cross linked or straight chain.During waste plastic pyrolysis, this long chain is broken down into smaller chain. The waste plastic pyrolysis machine turns waste materials into gases and liquids. The end products can be used in any standard diesel engine or generator with little or no modifications.

Pyrolysis of plastic to oil process machine technical data

Technical datar of Pyrolysis of plastic to oil process machine |

|

No. |

Items |

Contents |

|

1 |

Equipment type |

DY-1-6 |

DY-1-8 |

DY-1-10 |

|

2 |

Raw material |

Waste plastic |

Waste plastic |

Waste plastic |

|

3 |

Structural form |

Horizontal rotation |

Horizontal rotation |

Horizontal rotation |

|

4 |

24-hour Capacity |

6 ton |

8 ton |

10 ton |

|

5 |

Oil yield |

2.7-3.3ton |

3.6 -4.4ton |

4.5 -5.5ton |

|

6 |

Operating pressure |

Normal |

Normal |

Normal |

|

7 |

Material of pyrolysis Reactor |

Q245R |

Q245R |

Q245R |

|

8 |

Thickness of pyrolysis Reactor |

16mm |

16mm |

16mm |

|

9 |

Rotate speed of pyrolysis Reactor |

0.4turn/minute |

0.4turn/minute |

0.4turn/minute |

|

10 |

Total power |

19KW |

19KW |

19KW |

|

11 |

Mode of cooling |

Water cooling |

Water cooling |

Water cooling |

|

12 |

Cooling area of condenser |

100sqm |

100sqm |

100sqm |

|

13 |

Kind of transmission |

Internal gear drive |

Internal gear drive |

Internal gear drive |

|

14 |

Noise dB(A) |

≤85 |

≤85 |

≤85 |

|

15 |

Size of Reactor(D×L) |

2200×6000 |

2200×6600 |

2600×6600 |

|

16 |

Working form |

Intermittent operation |

Intermittent operation |

Intermittent operation |

|

17 |

Delivery time |

20days |

20days |

20days |

|

18 |

Weight |

27T |

30T |

35T |

|

Prepared by customer about Pyrolysis of plastic to oil process machine |

|

No. |

Item |

Consumption |

|

1 |

Coal(for choice) |

500kg/day |

|

2 |

Wood(for choice) |

800kg/day |

|

3 |

Natural gas(for choice) |

100-150kg/day |

|

4 |

Oil(for choice) |

300-350kg/day |

|

5 |

Electricity |

244kwh/day |

|

6 |

Water(recycled) |

60㎥ /month |

|

7 |

Total power |

19kw |

|

8 |

Land area |

35m*15m |

New product pyrolysis of plastic to oil process machine final product application

1. Crude oil (45%-50%): Oil from this machine can be used as industrial fuel for burning.

Fuel oil application

2. Carbon black (30%): First, Carbon black from this machine is crude oil . You can sell it to the brick factory as internal combustion or to the factory which need it as raw materials, such as shoe, tire, cable and sealant companies. Second, could make further process, make carbon black powder into carbon black briquette, and use it for burning.

Carbon black application

3. Waste gas (5%): we have a special design could recycling it into fire furnace for burning.