Continuous waste plastic pyrolysis plant

Continuous waste plastic pyrolysis plant

Continuous waste plastic pyrolysis plant

Continuous waste plastic pyrolysis plant

Continuous waste plastic pyrolysis plant technical data

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

Continuous waste plastic pyrolysis plant final product application

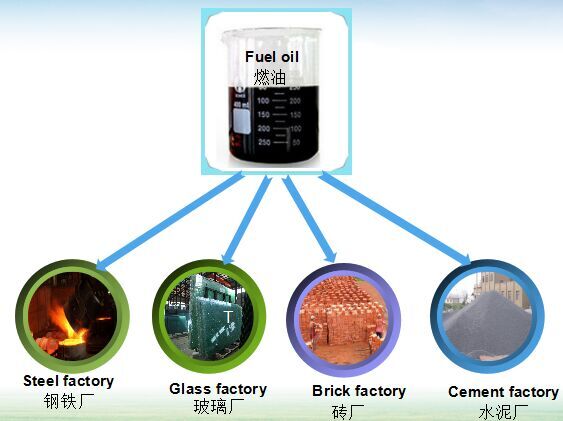

Fuel oil application of continuous waste plastic pyrolysis plant

The main application of oil products produced by our continuous waste plastic pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. 45% to 52% oil of the amount of recycled scrap plastic can be carried with licensed tanker trucks.

Carbon black application of continuous waste plastic pyrolysis plant

The second product of continuous waste plastic pyrolysis plant is carbon black. The quantity of carbon black is about 30% to 35% according to plastic quality. The use of carbon black is as a chemical strengthener in rubber and coloring agent in pigment industries. This carbon black price is very competitive compared to petroleum carbon black, so our pyrolysis carbon black is good option in stead of petroleum carbon black.

Request Information

Send your inquiry for further information