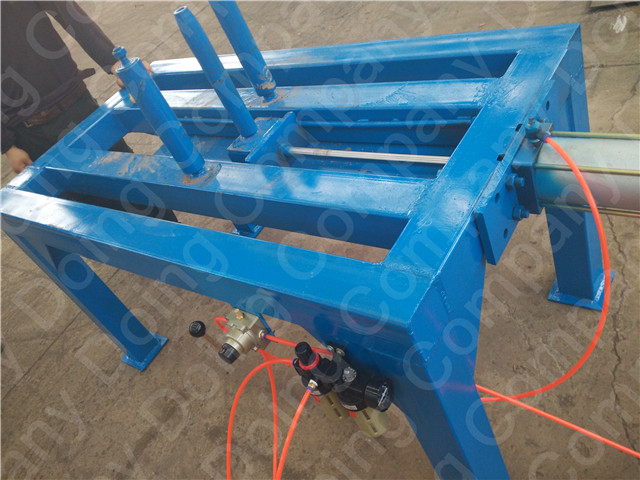

Tire baler

| Technical Parameters of tire baler | ||

| No. | Items | Contents |

| 1 | Machine | Tire baler |

| 2 | Function | Make several tires nested together with reversible unpacking function |

| 3 | Advantage | Save place for used tyre storing and transport |

| 4 | Length | 1.50m |

| 5 | Width | 0.85m |

| 6 | Height | 1.12m |

| 7 | Weight | 200kg |

| 8 | Power | Compressed air without electricity |

| 9 | Pressure | 6kg / 6bar / 0.6Mpa |

Compared to other tire processing machine, like tire cutting machine, this tire baler has several main advantages as below:

1. For some tyre dealers, they want to keep complete tyres for further use. So they don't want to cut tires for better storing and transport, then they can use the tire baler to make several tyres nested together firstly. After transport, they can unpack the tyres to normal for further use.

2. For some tyre pyrolysis factories, they want to fill as many tyres as possible inside the reactor for pyrolysis to oil. But as we all know that tyres contain steel wire which is difficult to press. This time you will need to use a tyre cutter to cut tyres into small pieces. But after cutting, the steel wire inside tyres will become small pieces mix with carbon black after pyrolysis process, which is difficult to separate. For tyre doubling machine, you can use it to make several complete tyres together, then put them into the reactor. It can not only save the plave, the steel wire inside tyres also can keep complete. After pyrolysis, the big steel wire can tangling together, which is easy to pull out by a hook.

3. This tire baler doesn't need electricity to work. It powered by compressed air. which can save so much energy.

4. Automatic packing machine is easier to operate and more efficiently. It can be operated by only one worker, which can make 3 tires nested together within 1 minutes.

So in conclusion, the tire baler ne can not only save the storage and transport cost, but also save the energy, the labour and the time.

Next:Tire doubler

Request Information

Send your inquiry for further information