Tyre to diesel?

Waste Oil Distillation Plant / Date:February 25, 2018

Tyre to diesel distillation plant

One of end products of tyre/rubber pyrolysis plant is rubber oil, which is also called as rubber pyrolysis oil or tyre oil. Tyre oil is mainly used as fuel for heating boiler. But it can be refined into diesel oil and gasoline by rubber oil to diesel refining machine for vehicles. It is the alternative energy for oil resource.

Tyre oil to diesel distillation plant will have huge economic and environmental benefits. According to the characteristics of rubber/tyre/plastic oil, Doing Group has researched and developed tyre oil to diesel fuel distillaiton plant, based on reduced pressure distillation technology. Reduced pressure distillation (vacuum distillation), refers to reduce the pressure inside the system by vacuum pumps, thereby reducing the boiling point of the liquid.

Tyre to diesel?

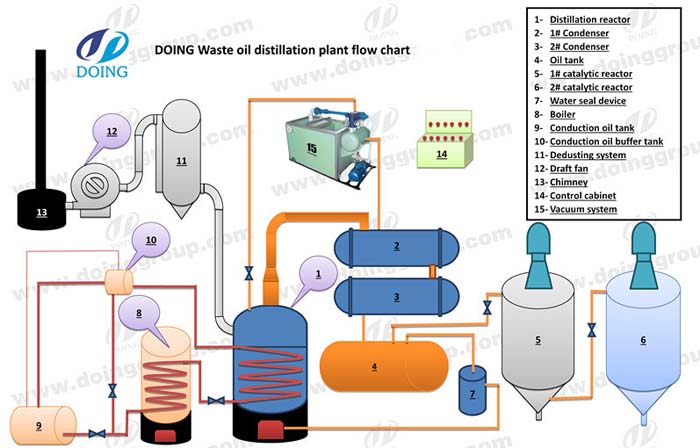

Tyre oil to diesel distillation plant working proces

First, pump the waste tyre oil into reactor by oil pump.

Second, use coal/wood/natural gas/fuel oil/electricity heating the reactor.

Third, after heating some time, the liquid oil will become oil gas, oil gas will be liquefied by the cooling pipe and condensers then will go into oil tank. Here we get mixed oil, or u can also call it fuel oil. If you wanna get diesel and gasoline separately, through temperature control could separate it and collected into two different oil tanks.

Fourth, some gases (syngas) like Methane, Ethane, Propane, Butane, and Hydrogen cannot be liquefied under normal pressure and normal temperature will be recycled to fire furnace heating the reactor.

Fifth, when use burning material heating the reactor, will produce some smoke. These smokes will go into our de-dusting system, the inside we design some high pressure nozzles, these nozzles will spraying some chemical water, the dust will be absorbed by the chemical water and flowing into the de-dusting pool. In the pool we will put some chemical which could remove the sulfur.

Request Information

Send your inquiry for further information