What is Tire Pyrolysis?

Waste Tire/Plastic Pyrolysis Plant / Date:February 9, 2017

Pyrolysis

Pyro = heat. Lysis = break down.

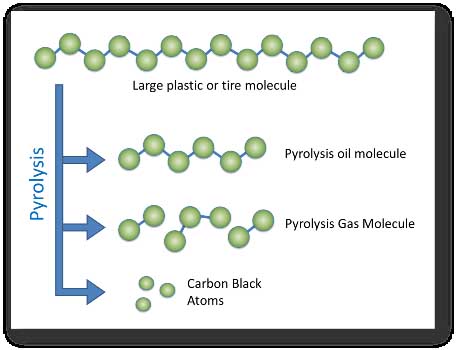

Pyrolysis is chemical reaction. This reaction involves molecular breakdown of larger molecules into smaller molecules in presence of heat. Pyrolysis is also known as thermal cracking, cracking, thermolysis, depolymerization, etc.

Tire pyrolysis is: the process of converting waste tires into industrial fuels like Tire Pyrolysis Oil, Carbon Black, Steel Wire and Hydrocarbon Gas.

Pyrolysis is chemical reaction. This reaction involves molecular breakdown of larger molecules into smaller molecules in presence of heat. Pyrolysis is also known as thermal cracking, cracking, thermolysis, depolymerization, etc.

Tire pyrolysis is: the process of converting waste tires into industrial fuels like Tire Pyrolysis Oil, Carbon Black, Steel Wire and Hydrocarbon Gas.

Waste tire pyrolyiss

Tire pyrolysis involves subjecting tire to high temperature of 400 to 450 degree Celsius, in absence of oxygen. In case of oxygen is present plastic will start burning. During pyrolysis tire breaks down into smaller molecules of pyrolysis oil, pyrolysis gas, steel wire and carbon black. Pyrolysis is a great way of recycling large amounts of tires. This plant can also used for waste plastic recycling. Pyrolysis gas is consumed to generate heat required for pyrolysis of tires. Suitable catalyst if used to increase process profitability.

- Tire shredding & conveying system

- Airlock feeding system

- Tire Pyrolysis Reactor

- Carbon airlock removal and cooling system

- Carbon bagging system

- Condensers for oil and gas separation

- Pyrolysis gas storage and reuse system

- Heating system

- Energy recovery system

- Automation control panels

- Tire Pyrolysis oil storage tank

Request Information

Send your inquiry for further information