Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>What are the purchase options for waste tire recycling plant that suitable for different processing scales?

Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>What are the purchase options for waste tire recycling plant that suitable for different processing scales?

What are the purchase options for waste tire recycling plant that suitable for different processing scales?

Waste Tire/Plastic Pyrolysis Plant / Date:September 15, 2021

Different types of waste tire recycling plant suit for different processing scales. Also, there are different types of waste tire recycling plant of different manufacturers. If you want to invest the waste tire recycling project, you should confirm: how many waste tire do you want to refine into pyrolysis oil? what is your budget? how many raw materials do you want to process per day? And what is the area of your pyrolysis plant workshop, etc. If you know these elemental information, Henan Doing is very glad to give you suggestions.

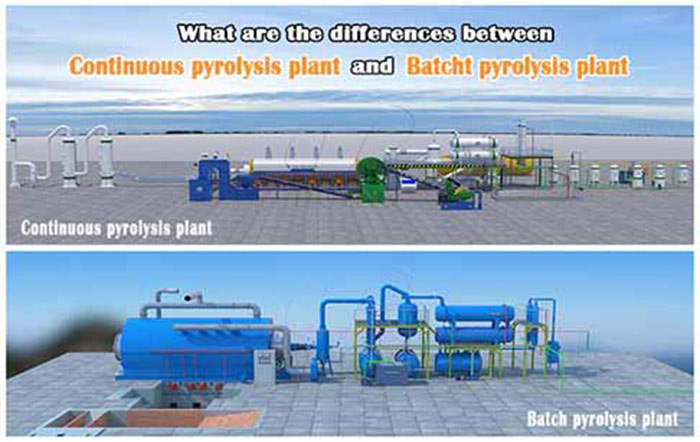

There are two kinds of waste tire recycling plant in Henan Doing Environmental Protection Technology Co.,LTD, including batch waste tire recycling plant and fully automatic waste tire recycling plant.

Batch and continuous waste tire pyrolysis plant

Batch and continuous waste tire pyrolysis plant

Batch waste tire recycling plant:

Batch waste tire recycling plant is suitable for small-scale operation under 15t processing capacity. If your daily processing capacity is not high, and the budget is limited, Doing recommends you choose batch waste tire recycling plant. The batch waste tire recycling plant has lower price and occupies a small size. And if your processing capacity is lower than 15T/D, you can only choose batch waste tire plant.

Batch waste tire plant is composed of pyrolysis reactor, cooling system, purification system and safety device. In order to make sufficient cooling effect and get the high oil output, the plant adopts 3-steps cooling system, thus get high oil yield. But the entire process of the plant needs two workers. Except for labour cost, electrics and others, the daily profit is still considerable.

Batch waste tire pyrolysis plant

Batch waste tire pyrolysis plant

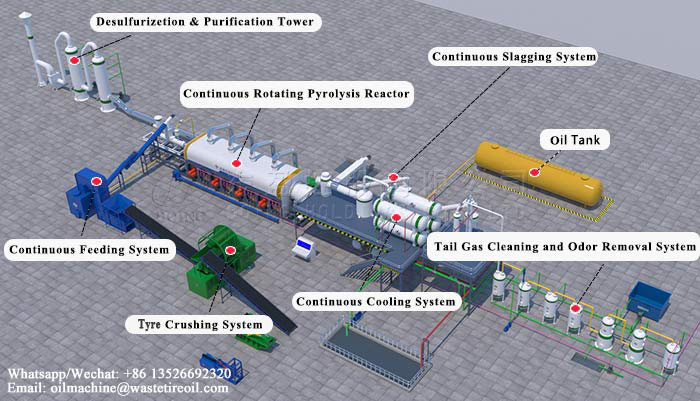

Fully automatic waste tire plant:

Besides, if you have a great amount of waste tire and want to improve the production efficiency, you should choose fully automatic waste tire plant. Because it is a new design of pyrolysis plant, controlled by PLC system, and it continuously feed and slag, thus no need to stop the machine and wait it to be cooled down for discharging carbon black. And waste tire recycling plant adopts accurate calculated pyrolysis system, which could ensure fully pyrolysis of the input, thus to get high oil output. Compared to the batch waste tire plant, this plant could process waste tire more than 20t per day. But the price of the fully automatic waste tire plant may be a little higher than the batch waste tire plant.

Continuous waste tire pyrolysis plant

Continuous waste tire pyrolysis plant

In addition to considering output and budget, land, policy and labor costs are also considered in the scheme of purchasing waste tire recycling equipment. If you have many questions about investment in waste tire recycling, you can consult Henan Doing. Our experienced engineers will provide appropriate solutions according to your needs to ensure your production efficiency, investment and production safety.

Request Information

Send your inquiry for further information