Waste plastic to oil process?

Waste Tire/Plastic Pyrolysis Plant / Date:January 30, 2018

Plastic to oil process

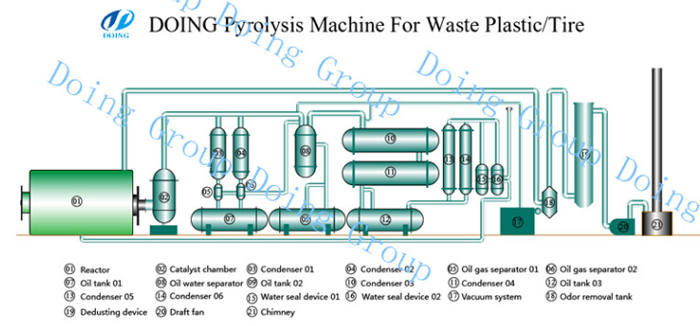

Waste plastic to oil process machine working process:

Waste plastic to oil process machine working process

2. After loading fully, if the plastic is not wet, after 6-8 hours the plastic oil gas come out, then the oil gas coming out will last 18-20 hours. That is mean after 18-20 hours the oil gas ran out.

During the heating period, the oil gas temperature(there is an thermal couple to test the oil gas temperature) need to control 270-300 Celsius degree, which is the best temperature. But if the lower temperature(lower than 270) u control the oil quality will be better,but it needs longer times(longer than 18-20 hours). If u did not required high oil quality then u can use the high temperature (higher than 300) this will be fast( shorter than 18-20 hours).

3. At same time,there are some gas(CH4, C2H6, C3H8, C4H10 and H2) can not be cooled under normal pressure,they will be recycled back to combustion system to burn as energy.

4. After the oil gas running out then 2 hours cooling we can discharging the carbon black.

5. after this then you can begin the next batch, no need to wait for the reactor become cool as we use machine loading the waste plastic.

Request Information

Send your inquiry for further information