How to make plastic bag to fuel oil?

Waste Tire/Plastic Pyrolysis Plant / Date:June 2, 2018

Waste plastic bags

Plastic bags involve all aspects of our lives and bring convenience to our lives. At the same time, discarded plastic bags also cause great problems for our lives. How to convert these white pollutions reasonably and not re-caused pollution to our living environment is a matter worthy of study and discussion.

DoingGroup's waste plastic bags to fuel oil pyrolysis plant

DoingGroup, standing in the forefront of the development of the industry, first proposed this idea how to convert plastic bags into fuel oil? And developed a waste plastic pyrolysis plant.

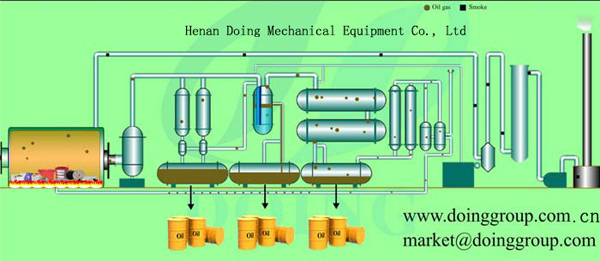

So how does the plant convert plastic bags into fuel oil? It mainly uses high-temperature pyrolysis chemical reaction, in the high temperature, closed, oxygen-free environment, so that waste plastics at high temperatures, the process of cracking out fuel oil, carbon black, and combustible gases. Of course, the conversion of waste plastics into fuel oil is not just so simple . Its specific process is as follows:

So how does the plant convert plastic bags into fuel oil? It mainly uses high-temperature pyrolysis chemical reaction, in the high temperature, closed, oxygen-free environment, so that waste plastics at high temperatures, the process of cracking out fuel oil, carbon black, and combustible gases. Of course, the conversion of waste plastics into fuel oil is not just so simple . Its specific process is as follows:

Waste plastic bags convert to fuel oil working process

1. The waste plastic is sent to the reaction vessel through a auto-feeder, and is heated by using coal, wood, oil, natural gas, and so on.

2. The temperature rises to about 200 degrees and begins to crack heavy oil and gas.

3. The heavy oil and gas oil is initially filtered by the catalyst chamber, and after deceleration, it enters the condensing system and is liquefied into heavy oil and falls into the oil tank.

4. Decolorization and deodorization of the obtained heavy oil, the final result is fuel.

5. The carbon black produced during the combustion process will eventually pass through the underground sealing channel and be automatically discharged outside the furnace. Due to better sealing performance, secondary pollution to the environment is avoided.

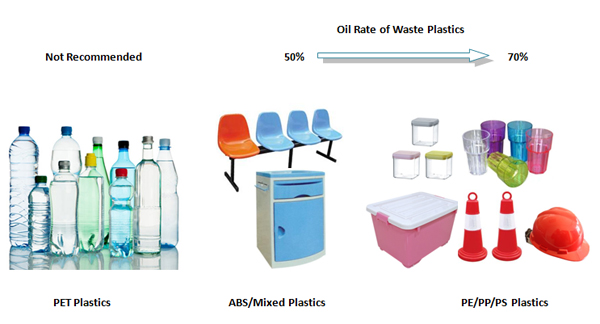

Through this process and based on different wastes materials, their oil output is also different:

All kinds of waste materials

| PE | 95% |

| PP | 90% |

| PS | 90% |

| ABS | 40% |

| Leftovers of paper | Wet 15-20%,dry 60% |

| House garbage | 35-50% |

| Plastic cable | 80% |

| Plastic bag | 50% |

| Submarine cable | 75% |

| Rubber cable | 35% |

| Sole | 30% |

| Big tires | 45-50% |

| Small tires | 35-40% |

| PVC | Not suitable |

| PET | Not suitable |

These substances have a very wide range of uses in life. Their specific uses are as follows:

1. Fuel oil:

Fuel oil application

1)It is sold as fuel to cement plants, glass factories, ceramic factories, power plants, steel mills, boiler plants, etc.

2)For heavy oil generators.

3)The Dongying Group's fuel oil distillation machine and decolorization and deodorization machine are used to deeply process fuel oil into diesel oil. Tyre diesel can be used for trucks, tractors, etc.

2. Carbon black:

Carbon black application

1)Made of spherical carbon black, carbon black briquettes for heating and burning.

2)Ground to N220, N330, N550 or N6660 for tire manufacturing industry.

3)Processed into masterbatch, sold to the plastics industry.

3. Combustible gas

1)Recycle to furnace, heat reactor, save your coal/wood/fuel oil/natural gas.

2)Store remaining exhaust gas for heating other furnaces.

2)Ground to N220, N330, N550 or N6660 for tire manufacturing industry.

3)Processed into masterbatch, sold to the plastics industry.

3. Combustible gas

1)Recycle to furnace, heat reactor, save your coal/wood/fuel oil/natural gas.

2)Store remaining exhaust gas for heating other furnaces.

Georgian customer's converts waste plastic bags into fuel oil pyrolysis plant

How to convert plastic bags into fuel oil? There are already very mature technologies and there are national policy support. You only need to spend less investment, you can bring huge profits later, is your best choice for investment!

Request Information

Send your inquiry for further information