Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>What's the necessary equipment for waste plastic pyrolysis plant?

Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>What's the necessary equipment for waste plastic pyrolysis plant?

What's the necessary equipment for waste plastic pyrolysis plant?

Waste Tire/Plastic Pyrolysis Plant / Date:May 14, 2021

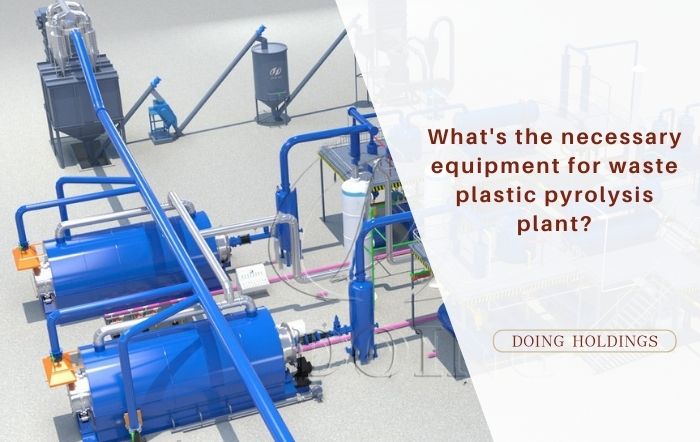

DOING company has manufactured waste plastic pyrolysis plant for over 10 years, and we can provide different designs and configurations for our customers to meet their different demands. Doing waste plastic pyrolysis plant is mainly composed of two parts: Pyrolysis reactor and condensing system. But there are also some other optional equipment available for customers to choose from. Every customer wants to know what equipment is necessary for waste plastic pyrolysis plant. Now, let's see more details.

What's the necessary equipment for waste plastic pyrolysis plant?

What's the necessary equipment for waste plastic pyrolysis plant?

1. The pyrolysis oil burners

Usually, this is the necessary optional equipment, because you can use the pyrolysis oil as the fuel to heat the pyrolysis reactor directly, then you don’t need to buy the fuel from others, which is very convenient and cost-saving. The 99% of our customers will almost choose to buy the burners.

Pyrolysis oil burner

Pyrolysis oil burner

2. The carbon black screw conveyor

It’s also a necessary equipment. After discharged from the pyrolysis reactor, the carbon black needs to be lifted from the underground carbon black pond. The use of the carbon black screw conveyor saves labor and time, and the equipment is inexpensive and has good cost performance.

Carbon black screw conveyor

Carbon black screw conveyor

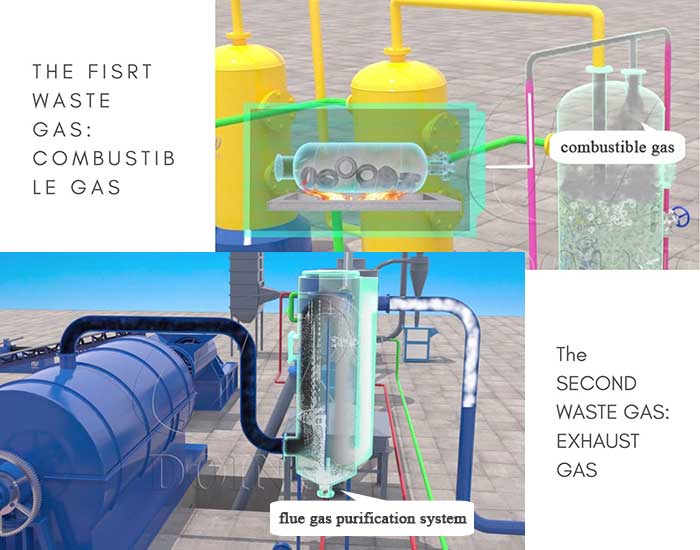

3.The environmental protection devices

(1) Tail gas purification system

It’s used to purify the tail gas produced from the pyrolysis process of waste plastic pyrolysis plant. Most of the tail gas is C1-C4 alkane combustible gas, but it also contains a small amount of hydrogen sulfide. Hydrogen sulfide is a pungent gas, which is very unpleasant, so we specially designed an exhaust gas purification system to remove hydrogen sulfide.

(2) Flue gas desulfurization tower

It’s a high-grade version of flue gas purification system. Doing waste plastic pyrolysis plant is equipped with standard flue gas purification system. But if you have a higher demand for the environmental protection, we also could provide the higher configuration device for you to meet your needs.

Environmental protection devices

Environmental protection devices

4. The auto-feeder

It’s used to feed the plastic into reactor, using it could save much feeding time. If you hire workers to feed plastics, you need to take about 4 hours, but if you use the auto-feeder, it just takes about 1.5-2 hours to feed.

5. The vacuum system

It’s a safety device. It is used to extract remaining oil gas from the reactor after finishing pyrolysis, which can avoid the fire caused by the oil gas when you oped the door of the reactor.

Henan Doing company has been engaged in waste plastic pyrolysis plant for more than ten years, and has developed two types of waste plastic pyrolysis plant: batch waste plastic pyrolysis plant and continuous waste plastic pyrolysis plant. You can choose the right waste plastic pyrolysis plant according to your actual situation. For more information, welcome to leave us your message below, we will contact you asap.

Request Information

Send your inquiry for further information