Machine that turns plastic into oil for sale ?

Waste Tire/Plastic Pyrolysis Plant / Date:April 22, 2017

Plastic to oil machine

As the application of the plastic products becomes wider and wider, the pollution caused by plastic waste is also a huge problem. Some of the developed countries have put many emphasis on developing the plastic waste recycling technology.

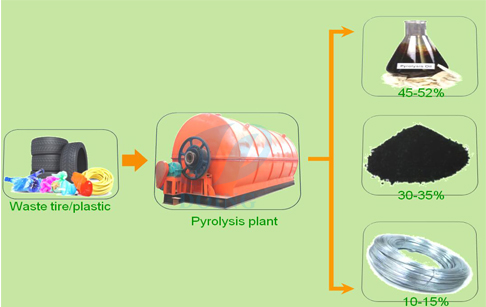

Machine that turns plastic into oil

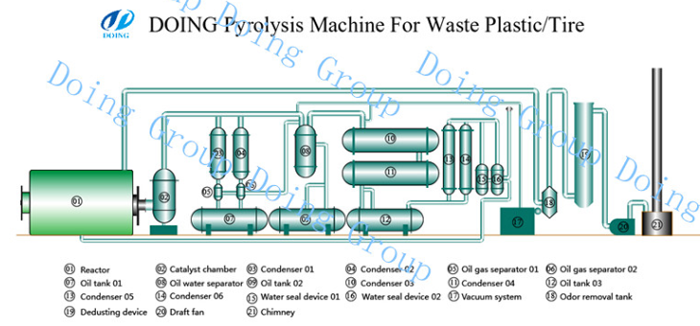

Machine that turns plastic into oil working process

(1)Feeding-in system:

The raw material can be waste tyres, rubbers or plastic. If your raw material is plastic, we suggest that you use the auto feeder. If your raw material is waste tires, we suggest that you use belt conveyor.

(2)Pyrolysis system:

The reasonable thickness, it is easy to heat and easy to be cool down.

(3)Heating system:

There are various kinds of fuel, such wood, charcoal, coal, LPG etc.

(4)Deducting system:

They usually have one or two equipments for deducting, we the three, desulfurization scrubber, water film cyclon and the advanced bag deduster.

(5)Impurities removing system:

There are two devices for removing the impurities from the oil gas, one is gas separate tank, the other is depositing tank.

(6) Cooling system:

We have the new design for the cooling system; it has better cooling effect and high oil yield.

(7)Oil Store system: For store the oil.

(8)Waste gas recycling system:

It is also named water seal, it has two effects, and one is for the gas separate tank, the other is depositing tank.

(9)Carbon black discharging system:

The carbon black is coming out automatic; there also has a screw conveyor for removing the carbon black.

With the development of the society, people put more emphasis on the environmental protection, and the machine that turns plastic into oil pyrolysis plant will also have a bright future.The waste plastic recycling industry has a promising developing trend, because it can not only protect the environment, but can also save energy.

Request Information

Send your inquiry for further information