Can plastic be converted into fuel?

Waste Tire/Plastic Pyrolysis Plant / Date:September 14, 2018

Plastic to oil conversion pyrolysis plant

Plastic is the use of monomer materials to synthesis or condensation reaction of the material. Wide range of plastic, more useful, easy to color, part of the high temperature, and easy processing can be mass-produced, the price is cheap, but a large number of waste plastics also give our living environment caused serious pollution. DOING company in order to ease the energy crisis and environmental pollution, developed a plastic to oil conversion pyrolysis plant. It is the use of high temperature cracking chemical reactions, the cracking of waste plastics into fuel, carbon black, non-condensable gas process.

Can plastic be converted into fuel?

Plastic to oil conversion pyrolysis plant

Yes,Henan Doing produced plastic to oil conversion pyrolysis plant adopts advance pyrolysis technology that conversion plastic waste to fuel oil and carbon black.

Plastic to oil conversion pyrolysis plant working process

The raw material can be waste tyre/waste plastic/waste rubber. Always feed by the auto feeder.

2.Pyrolysis

Include a reactor and catalyst room. Heat the reactor by coal/wood/oil/natural gas. This part will produce high temperature oil gas, the oil gas then flow into the next system.

3. Condensing

Oil gas come out from the reactor and catalyst chamber then cooling down in this part. Condensing system include condenser pipe, oil water separator, horizontal condenser and waste gas condenser. This will make the plastic to oil conversion pyrolysis plant oil yield to the maximum.

4.Waste gas recovery

This part mainly deal with the gas that cannot be condensed. The plastic to oil conversion pyrolysis plant process is very steady and high efficiency.

5. Discharge

After finished oil produce, the temperature of reactor can be cooled down, When the temperature falls down to 40 degree then carbon black can be discharged automatically by the way of anticlockwise rotate the reactor. The carbon black will drop into slag pool and then use screw conveyor to clean the slag pool. After discharging the carbon black.

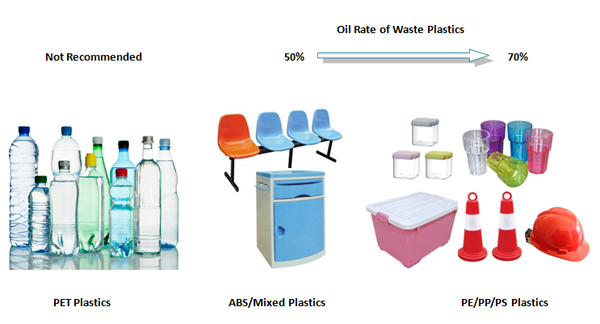

After the plastic to oil conversion pyrolysis plant working process ,we can get fuel oil ,carbon black ,gas. Some customer may wonder to know how is the fuel oil yield we can get final ,well ,as many people may know ,different kinds waste plastic oil content is different ,so the oil yield is also different.We have summarized several common waste plastic oil yields for your reference:

Different kinds waste plastic oil yield

Can plastic be converted into fuel?This question is affirmative.But to choose one high quality plastic to oil conversion pyrolysis plant before you convert the waste plastic to fuel oil is important.We have many years experience in plastic to oil conversion pyrolysis plant manufacture.Our plastic to oil conversion pyrolysis plant have been exported all over the world,such as France, Italy, Czech Republic, India, Nigeria, United Arab Emirates, Canada, the Philippines and other countries.

DOING company plastic to oil conversion pyrolysis plant project cases all over the world

We will provide you with a complete set of project feasibility reports and post-equipment equipment installation and equipment operation testing services.If you want to dispose the waste plastic/tires/rubber,DOING company's plastic to oil conversion pyrolysis plant must be your best choice!!

Request Information

Send your inquiry for further information