Waste plastic pyrolysis plant

The environmental pollution caused by plastic waste has been widely concerned by the world. Whereas waste plastic pyrolysis plant can provide an opportunity to collect and process plastic waste in the most environmentally friendly way. Moreover, during this processing, plastic waste can be converted into fuel oil and carbon black which can be used in many industrial fields. After years of research and development, Doing Group has mastered the advanced pyrolysis technology and designed environmentally friendly and efficient waste plastic pyrolysis plant. Now let's see the detailed information.

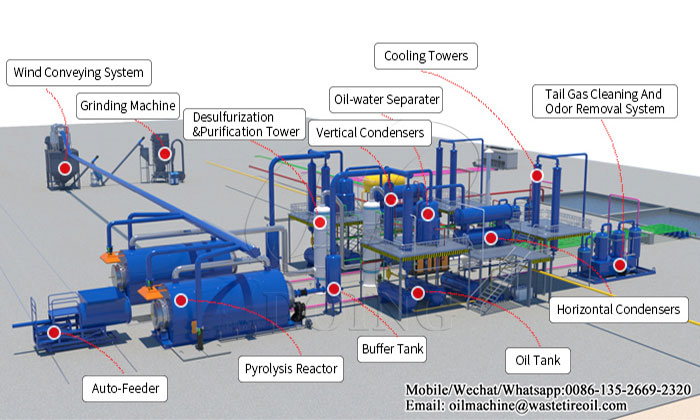

▶ The composition of Doing waste plastic pyrolysis plant:

Doing waste plastic pyrolysis plant

Doing waste plastic pyrolysis plant

Auto-feeder, pyrolysis reactor, horizontal condenser, vertical condenser, cooling tower, oil tank, oil-gas separator, negative pressure device, tail gas cleaning system, control cabinet, carbon black discharge device, flue gas cleaning system, etc.

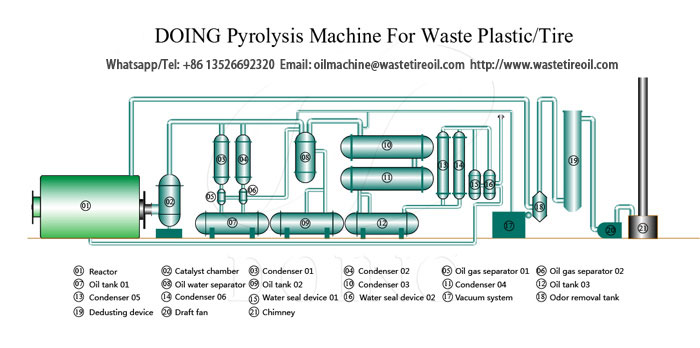

▶ The operation of Doing waste plastic pyrolysis plant:

Doing waste plastic pyrolysis plant operation

Doing waste plastic pyrolysis plant operation

First, put waste plastic into the pyrolysis reactor through auto-feeder, close in-let and heat the pyrolysis reactor. When the temperature reaches 160 degrees Celsius, waste plastic will be evaporated into oil gas. The highest yield is achieved when the temperature rises to 200 degrees Celsius to 300 degrees Celsius. Then oil gas will enter the condensing system and liquefy into heavy oil, which will be collected in the oil tank. And the gas that cannot be liquefied will be recycled to the furnace chamber to assist in heating the pyrolysis reactor. The flue gas generated from heating can be discharged to the air after the purification system to meet the environmental requirements. At last, after the pyrolysis reaction is finished, stop heating the pyrolysis reactor, and then carbon black can be discharged when the temperature of the pyrolysis reactor is lowered to about 50 degrees Celsius.

Waste plastic pyrolysis plant technical data

| Technical Parameter of Waste Plastic Pyrolysis Plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Our company possesses strong capabilities in providing customized pyrolysis plant tailored to meet the needs of plastic recycling projects, ranging from small-scale to large-scale operations, with the processing capacity from 100kg/batch to 50Ton/Day/Set. We offer a diverse range of equipment models designed to suit various project sizes and specifications. Our research and development team has designed pyrolysis plants for sale in four distinct types: skid mounted type, batch type, semi-continuous type, and full-continuous type, each with its unique features and advantages to accommodate a wide range of recycling requirements.

Waste plastic pyrolysis plant types

Waste plastic pyrolysis plant types

The skid-mounted type waste plastic pyrolysis plant is characterized by its simple structure and ease of installation, making it an ideal choice for small to medium-sized plastic recycling projects with lower investment costs and quick setup times.

The batch-type plastic scrap pyrolysis plant is well-suited for handling complex plastic waste materials, offering flexible operation and efficiency in processing various types of plastic, with easy operation and fast processing times.

For medium to large-scale projects, we provide semi-continuous and full-continuous waste plastic pyrolysis plant. Semi-continuous pyrolysis systems are known for their high processing efficiency, offering partial automation and improved production rates, making them ideal for businesses that require high throughput. On the other hand, the full-continuous pyrolysis plant is designed for large-scale operations, providing non-stop production with minimal human intervention. This high-performance equipment is capable of processing a wide variety of plastic materials, ensuring stability and efficiency for extended periods, making it the perfect solution for businesses aiming for continuous, large-scale production.

With these versatile pyrolysis equipment options, we Henan Doing Company are able to offer tailored solutions to our clients, helping them achieve efficient plastic waste processing and resource recovery. In today's environmentally conscious and resource-driven world, our equipment provides customers with cost-effective, eco-friendly, and high-performance plastic recycling solutions to support their sustainable development goals.

The applications of the final products from waste plastic pyrolysis plant

Pyrolysis equipment is capable of processing a wide variety of plastic materials like PP(Polypropylene)/PE(High&Low Density Polyethylene)/PS(Polystyrene)/ABS/Plastic Bags/Paper Mill Waste/Plastic Pellet/Plastic Films, etc, transforming them into valuable resources.The final products of waste plastic pyrolysis plant are mainly fuel oil and carbon black, and both of them have a wide range of applications in different fields.

Waste plastic pyrolysis oil yield

Waste plastic pyrolysis oil yield

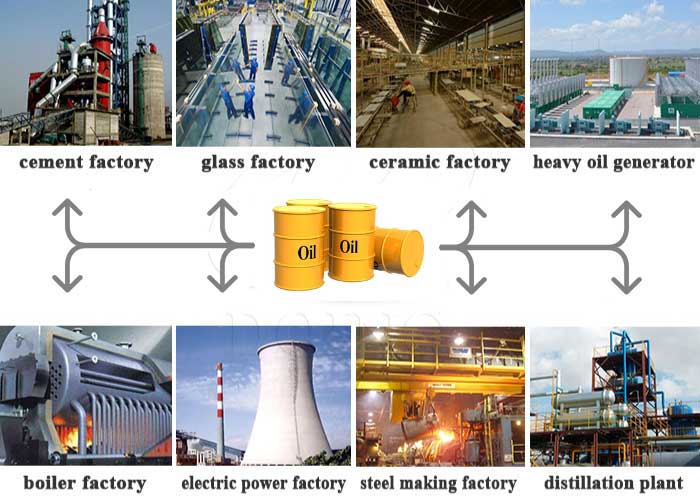

1.Fuel oil

The fuel oil can be directly sold as fuel for industrial enterprises such as cement factory, glass factory, ceramic factory, electric power factory, steel making factory, boiler factory, etc. What's more, it can also be refined by plastic pyrolysis oil distillation machine to get diesel, a higher economic value fuel oil.

Fuel oil application

Fuel oil application

2.Carbon black

It can be directly sold, or made into briquettes, used for heating and burning, or milled into powder, widely used in new tires, shoe soles, or paint.

Carbon black application

Carbon black application

3. Syn-gas

The syn-gas generated in the waste plastic pyrolysis process is usually recovered for heating pyrolysis reactor to save investment cost.

Request Information

Send your inquiry for further information