New technology continuous waste tyre pyrolysis plant

New technology continuous waste tyre pyrolysis plant

New technology continuous waste tyre pyrolysis plantAs a professional pyrolysis plant manufacturer, Doing group has exported products to more than twenty countries. Among them, our continuous waste tyre pyrolysis plant is proved to be high efficiency and high cost-effective.the continuous waste tyre pyrolysis plant which has many latest designs. First, it is equipped with automatic feeding system and two sealed discharging systems, which makes it easier and more safe to operate. Second, it not only can dispose 10-100 tons of waste plastics per day, but also can work continuously for 24 hours per day without a stop. These new designs make it very popular among many customers.

New technology continuous waste tyre pyrolysis plant working process

New technology continuous waste tyre pyrolysis plant working process

Continuous pyrolysis process: Shredded tyres go into the continuous waste tyre pyrolysis plant, will firstly go through a mutiple pyrolysis reactor system to be pyrolyzed into oil gas. And oil gas will be cooling down to liquid oil through the cooling system. The residues (carbon black) will be pushed by continuous feeding tyres to the carbon black dischrge system for discharge.

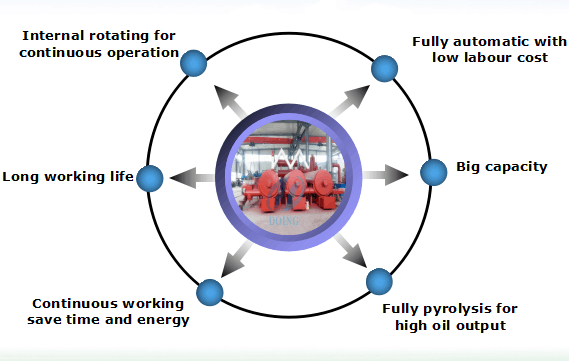

New technology continuous waste tyre pyrolysis plant advantage

New technology continuous waste tyre pyrolysis plant advantage

Technical Data of continuous waste tyre pyrolysis plant

| Technical parameter of continuous waste tyre pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyre | Waste tyre | Waste tyre |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about continuous waste tyre pyrolysis plant | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

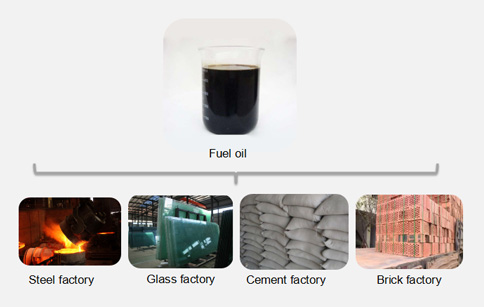

Application of continuous waste tyre pyrolysis plant final product

Application of continuous waste tyre pyrolysis plant final product

1.the usage of final production-----Fueloil

Fuel oil from waste tyre are used in below industries

A.power plant factory

B.glass factory

C.cement factory

D.ceramic factory

E.aluminum factory

F.boiler factory

G.central heating factory

H.painting factory

The usage of final production-----Carbon black

Carbon black from waste tyre are used in below industries

A.electric cable jacketing

B.conveyor ban

C.hose and doormat

D.black nylon bag

E.rubber additive

F.automatic spare parts

G.heat isolation

H.black colorant in rubber materials

Request Information

Send your inquiry for further information