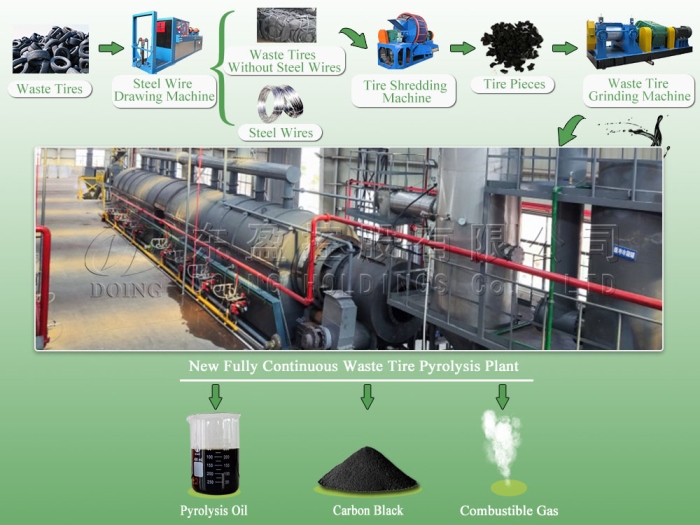

Continuous pyrolysis plant of plastic and waste tires

In order to effectively deal with the environmental pollution problems caused by waste tires and waste plastics, Doing engineers specially designed intermittent pyrolysis plant and continuous pyrolysis plant to treat waste tires and plastics to produce fuel oil, carbon black and steel wire after years of research. Both intermittent pyrolysis plant and continuous pyrolysis plant use the pyrolysis principle to dispose of waste tires and plastics environmentally friendly.

Continous pyrolysis plant of plastic and waste tires

Continous pyrolysis plant of plastic and waste tires

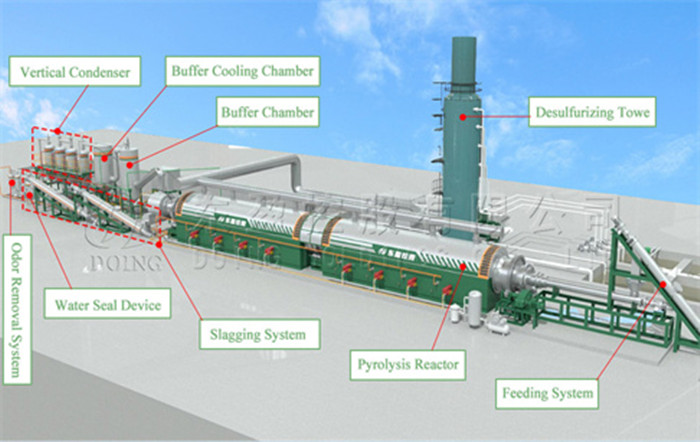

DOING continuous pyrolysis plant of plastic and waste tires is mainly composed of pyrolysis reactor, oil tank, horizontal condenser, vertical condenser, buffer chamber, negative pressure chamber, desulfurization & dedusting tower, slagging screw conveyor, square/round carbon black box, circulating water pump, vacuum pump, etc. All of parts are manufactured with high-quality materials and advanced technologies, so the quality of this plant can be guaranteed.

Continous pyrolysis plant of plastic and waste tires 3D picture

Continous pyrolysis plant of plastic and waste tires 3D picture

Here are a few reasons why the continuous pyrolysis plant of plastic and waste tires from Doing manufacturer has become so popular as an investment.

1. It is equipped with a precisely calculated pyrolysis system, which can monitor the pyrolysis process in the reactor in real time and adjust automatically to ensure the full pyrolysis of plastic and waste tires and obtain high oil yield.

2. It can run 24 hours without any downtime.

3. It is fully automatic controlled, with high degree of automation and easy operation. With continuous feeding and slagging system and PLC control system, only 1-2 workers are needed to operate, which saves labor cost.

4. It has a unique sealing design of feeding and slag discharge system to prevent the fumes from entering the air, which provides safety assurance and environmental protection.

5. Its capacities are bigger, Doing Group supplies 10TPD, 20TPD, 30TPD, 50TPD continuous pyrolysis plant of plastic and waste tires for your choice. And we can also customize different capacities of continuous pyrolysis plant of plastic and waste tires according to your situation.

Technical data of continuous pyrolysis plant of plastic and waste tires

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

Final product of continuous pyrolysis plant of plastic and waste tires

The final products of continous pyrolysis plant of plastic and waste tires are fuel oil, carbon black and steel wires(for waste tires only). And all of them can be applied in many different ways. The main applications of fuel oil produced by Doing continous pyrolysis plant of plastic and waste tires are used as fuel in glass factore, brick factory, cement factory ,etc. And the main applications of carbon black are used to make pellet, highway, new tire, shoe sole, etc. And the steel wires can be sold directly on the market.

Fuel oil application

Fuel oil application

If you have any questions about our Doing continous pyrolysis plant of plastic and waste tires, welcome to contact us.

Request Information

Send your inquiry for further information