Continuous pyrolysis plant for tires recycling

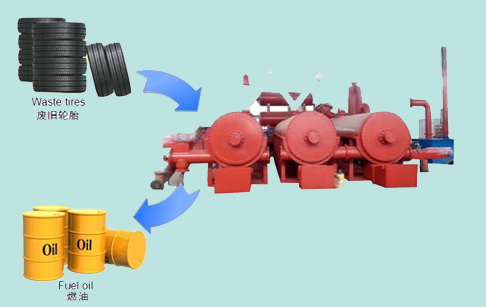

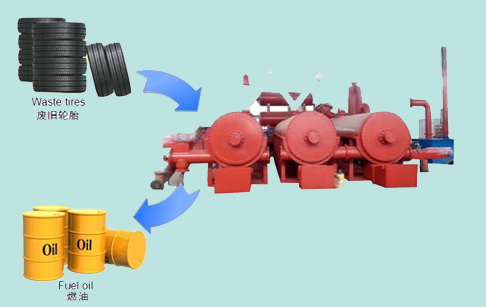

Doing have a technologically developed continuous pyrolysis plant for tires recycling, which is used for generating energy from the waste tires. These continuous pyrolysis plant for tires recycling are efficient way for disposing of such non biodegradable waste, where the organic materials is heated in the absence of oxygen or other reagents that produces gas, oil, carbon black and steel. Our continuous pyrolysis plant for tires recycling is also capable of treating the rubber and industrial plastic waste.

Product introduction of continuous pyrolysis plant for tires recycling

Through continuous improvement and constant technology upgrading,Doing have designed continuous pyrolysis plant for tires recycling which can convert tire into useful resources more efficiently. This series daily processing capacities range from 10 to 100tons.

Continuous pyrolysis plant for tires recycling

The main feature of this series of plants is that they can work continuously for 24 hours per day without a stop. Another advantages of this plant is that it can dispose waste tires in an environment friendly manner. Continuous pyrolysis plant for tires recycling is equipped with safety device (Alarm for over temperature and pressure, Auto pressure releasing system, extra gas recycling system, Fire fighting devices) and advanced dedusting system (water spray, ceramic ring filter, washing chamber), which will guarantee safety and no pollution in production.

Continuous pyrolysis plant for tires recycling picture show

Continuous pyrolysis plant for tires recycling picture show

Technical data of continuous pyrolysis plant for tires recycling

Final product application of continuous pyrolysis plant for tires recycling

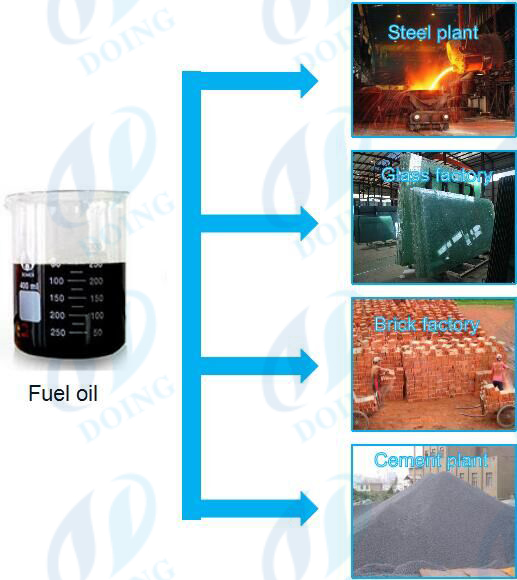

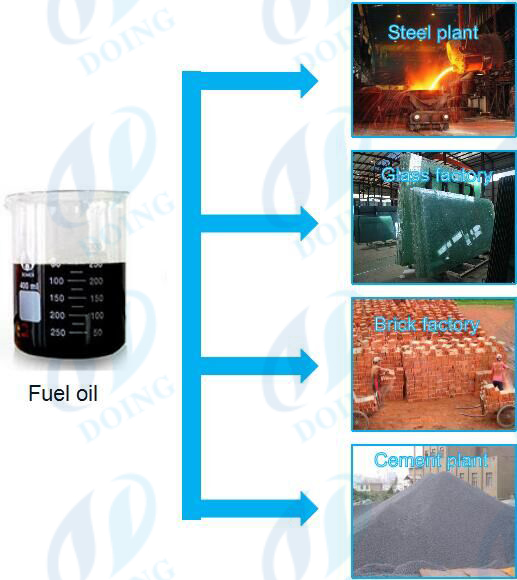

Fuel oil application application

The tire pyrolysis oil can be widely used as fuel oil in industries such as steel and iron and boiler factories, ceramics, power or chemical industries etc. If further refined to diesel or gasoline, it can be directly used in engines and generators. With the demand of oil increasing, the market price of tire pyrolysis oil will surely become higher and higher in the future. The carbon black and steel wire also a wide range of applications, which can create more benefits for you.

Product introduction of continuous pyrolysis plant for tires recycling

Continuous pyrolysis plant for tires recycling

Continuous pyrolysis plant for tires recycling picture show

Continuous pyrolysis plant for tires recycling picture show

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

Final product application of continuous pyrolysis plant for tires recycling

Fuel oil application application

Request Information

Send your inquiry for further information