Home > Product > Waste Oil Distillation Plant>Tyre/Plastic/Rubber fuel oil to diesel oil project report

Home > Product > Waste Oil Distillation Plant>Tyre/Plastic/Rubber fuel oil to diesel oil project report

Tyre/Plastic/Rubber fuel oil to diesel oil project report

Waste Oil Distillation Plant / Date:11-27-2020

Background of waste to fuel pyrolysis distillation plant project

Background of waste to fuel pyrolysis distillation plant project

1. The background and practical significance of project development

In an era defined by escalating global demand for energy, volatile oil prices, and the pressing imperative for environmental sustainability, the efficient recycling and upgrading of waste materials into valuable fuel products has emerged as a critical strategic priority. Experts consistently highlight that the world's accessible oil reserves are finite, and projections indicate a significant decline in supply within the coming decades. This looming "energy inflection point" necessitates a proactive shift towards alternative and renewable energy solutions.

Governments and industries worldwide are increasingly prioritizing the recovery and upgrading of waste hydrocarbons as part of sustainable development and circular economy strategies. Against this backdrop, our distillation technology for converting tyre, plastic, and rubber-derived fuel oil and other waste oils into high-quality diesel fulfills a clear international demand: it enables on-site upgrading of locally sourced waste streams into saleable diesel-range products, supports energy security, lowers environmental burden, and creates economic value across supply chains.

These initiatives not only generate substantial economic benefits, fostering job creation and economic growth, but are also actively encouraged and supported by national policies, indicating a profoundly promising future. The underlying technologies, often characterized by their simplicity, ease of implementation, and immediate, tangible results, are ideally suited for adoption by a wide range of entities, from large industrial operations and collectives to individual entrepreneurs. The proactive development and intelligent utilization of abundant waste oil resources are undeniably poised to become one of the most lucrative and forward-thinking emerging industries of the 21st century.

Pyrolysis oil/waste fuel oil distilltion machine

Pyrolysis oil/waste fuel oil distilltion machine

2. Overview of recyclable Oils and Technological Development

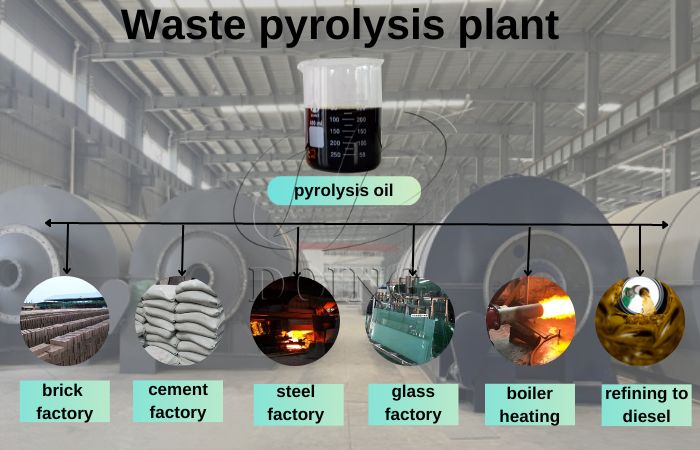

The scope of recyclable oil streams is extensive and growing, encompassing a diverse range of waste by-products that can be transformed into valuable fuels. To enhance the added value of these wasre fuel oil without compromising on cost-effectiveness. The most direct and impactful solution lies in the re-distillation of pyrolysis fuel oil and other used oils.

The core of our solution lies in the sophisticated waste oil distillation plant we have developed. To address the varying quality of available pyrolysis oil purification systems, we embarked on extensive research and development. Our engineers studied large-scale petrochemical distillation processes, integrating their strengths while innovating to overcome their limitations for smaller-scale, waste-oil applications. After years of dedicated scientific research and technological refinement, we successfully designed and launched Doing Group's patented purification and distillation system.

This waste oil distillation plant, boasting independent intellectual property rights, is specifically engineered to upgrade tyre, plastic, rubber pyrolysis oil and other used oils into high-quality light diesel. The distillation process effectively removes impurities and enhances the fuel's properties. The resulting product is typically a light-yellow liquid whose key technical indicators, such as viscosity, flash point, and sulfur content, can approximate those of standard 0# or -10# diesel. This upgraded diesel can be used as a direct substitute, commanding a market price significantly higher—by approximately 150-300 USD per ton—than the original fuel oil or crude pyrolysis feedstock, thereby substantially increasing project profitability and sustainability.

Rubber tyre plastic pyrolysis fuel oil to diesel distillation plant

Rubber tyre plastic pyrolysis fuel oil to diesel distillation plant

3. Several major components of thetyre/plastic/rubber fuel oil distillation machine

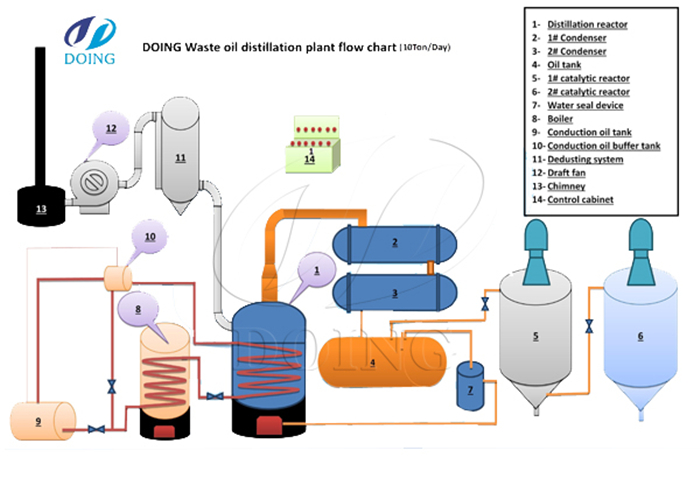

1). Each device consists of the following components: a. Control cabinet. b. Thermal oil system. c. Vertical reactor. d. Vertical and horizontal condensers. e. Oil tanks. f. Water seal. g. catalyst system(there are two types to choose from, solid catalyst or liquid acid-alkali catalyst to choose from) h.Decolorization and deodorization tower.

Pyrolysis fuel to diesel oil distillation machine catalyst refining technologies

Pyrolysis fuel to diesel oil distillation machine catalyst refining technologies

2). The company promises: The company sold a variety of series of equipment with perfect after-sales service, the warranty period of one year, completely resolved the customer's worries.

4. Product and Raw Material Market

Driven by global demand for renewable energy and sustainable waste management, the market for pyrolysis oil distillation and waste oils refining is growing rapidly.Pyrolysis oil, derived from the thermal decomposition of waste materials like tyres, plastics, and rubber, is emerging as a viable alternative fuel. The global production of waste oils is significant, with an estimated 1.3 billion gallons of used motor oil produced annually worldwide. In addition, industries such as automotive, shipping, and manufacturing contribute to a continuous supply of waste oils like lubricants and cooking oils, further expanding the market.Therefore, there is no need to worry about the waste oil and pyrolysis fuel oil collection.

5. The main technical features of tyre/plastic/rubber fuel oil distillation machine

1). Double heating system can ensure the system can be heated quickly and improve the operation efficiency of the equipment.

2). The interior of the heating system adopts calandria heating design to ensure evenly heating.

3). Vertical reactor design to facilitate slagging.

4). The cooling system is cooled by circulating water, which can recycle water resources without causing pollution and waste. It is energy-saving and environmentally friendly.

6. Distillation machine applicable feedstock products and industries

1). Fuel oil pyrolysis from waste plastics and waste rubber. . .

Foremost among these, and directly addressed by our advanced distillation technology, is the pyrolysis fuel oil derived from the thermal decomposition of waste tyres, plastics, and rubber with pyrolysis machine. This fuel oil, often a dark, viscous liquid, which is similar to high calorific value heavy oil. This pyrolysis fuel oil, while a valuable energy source, often requires further refinement to meet specific fuel standards and maximize its economic value.

Rubber tyre plastic pyrolysis fuel applications

Rubber tyre plastic pyrolysis fuel applications

2). Waste oil. Beyond pyrolysis fuel oil, our distillation plants are also highly effective in processing other waste oils, including but not limited to: waste diesel engine oil, waste engine oil, waste oil residue, waste motor oil, waste ship oil tank bottom cleaning washing oil, etc.

Used Oils: This ubiquitous waste stream, generated from the routine maintenance of automotive, marine, and industrial machinery, is a prime candidate for regeneration. During its service life, lubricating oil becomes contaminated with metallic particles, combustion by-products, and sludge, degrading its performance. Our technology can effectively remove these impurities, restoring its usability.

Industrial Waste Oils: This category includes a broad spectrum of oils from various industrial processes, such as hydraulic oils, gear oils, and transformeroils, which, after appropriate pre-treatment, can be refined into usable fuels.

7.Tyre/Plastic/Rubber fuel oil to diesel oil machine process flow

The tyre/plastic/rubber pyrolysis fuel oil, waste oil that requires deep processing is pumped into the reboiler through the oil pump, and heated under the normal pressure to distill the oil vapor. The oil and gas passes through the solid catalyst tower(if adopts solid catalyst technology) and enter the condenser, which can be liquefied and condensed into diesel oil. The non-liquefiable part is sent to the heating system through the gas system to burn off. Then the collected diesel will go through the acid and alkali liquids for refining. (if adopts liquidcatalyst technology) Besides that, we also have purification system to filter the fuel to obtain brighter and cleaner diesel.

Used oil/pyrolysis fuel oil to diesel distillation machine working process

Used oil/pyrolysis fuel oil to diesel distillation machine working process

8. Security

1). Indirect and direct heating two heating methods to protect the reactor safety;

2). Thermometers, pressure gauges, etc., display settings and alarms, etc.; Water seal

9. Environmental protection

Treatment of the three wastes in the production process.

1). Exhaust gas. Through the water film dust removal, the generated exhaust gas is sprayed in three layers, and the filtered exhaust gas is finally harmlessly discharged.

2). Waste liquid. During the processing of oil products, waste water will be generated and will be recycled after sedimentation and other treatments.

3). Waste solids. After theTyre/Plastic/Rubber fuel oil to diesel oil machine process, there will be some solid residues, which will account for about 5% to 10% of the weight of the raw materials. The main component is asphalt. In the market can be sold as a production bitumen.

10. Analysis of economic benefits

Through this process, we can obtain 80-85% diesel and 15-20% asphalt. we willget the following inputs and outputs for profit analysis.

Used Oil/Pyrolysis fuel oil distillation machine profit analysis

Used Oil/Pyrolysis fuel oil distillation machine profit analysis

1). Operating costs

Waste oil: 10 tons X288 US dollars / ton = 2868 US dollars

Heating the fuel can use any of the following:

1) Coal: 0.4 tons X 64 dollars/ton = 25 dollars

2) Fuel: 0.6 tons x 478 dollars/ton = 287 dollars

3) Diesel: 0.5 ton X 765 U.S. dollars/ton = 382 U.S. dollars

4) Natural gas: 200m23 X 0.36USD / m3 = 72USD

Power consumption: 25KW / h X O.16USD X 20h = 80h

Water consumption: reuse in water, almost no consumption

Workers: 1-2 people X 16 dollars = 32 dollars

2). Earnings/day

Fuel: 8 tons X 765 dollars/ton = 6118 dollars

Asphalt: 1.5 tons X 175USD/ton = 263 dollars

3). Profit/day (calculated on fuel diesel) of $3017.

11. Conclusion

According to the above analysis and calculation, it is shown that the use of waste tyre/plastic/rubber fuel oil, waste engine oil, and waste motor oil as raw materials for deep processing is technically advanced and feasible,Tyre/Plastic/Rubber fuel oil to diesel oil machinewith less investment, more raw materials, and quick results and good prospects. It is the best choice for investing and setting up factories.

Technical parameters ofTyre/Plastic/Rubber fuel oil to diesel oil machine

| Technical parameter of Tyre/Plastic/Rubber fuel oil to diesel oil machine | |

| Items | Contents |

| Model | DY-D-1t, DY-D-3t, DY-D-5t, DY-D-7t,DY-D-10t, DY-D-14t,… |

| Raw material | Waste rubber tire pyrolysis crude oil, plastic crude oil, used motor oil, waste engine oil, heavy oil, mazut, etc. |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 80-85% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Diesel oil made from crude oil machine can finally get 80-85% diesel and 15-20% asphalt. They have a very wide range of use values:

Applications of diesel and adphalt extracted from crude pyrolysis oil

Applications of diesel and adphalt extracted from crude pyrolysis oil

1. Diesel oil: Can be used for heavy machinery, diesel generators, boiler heating, trucks, tractors, etc.

2. Asphalt: It can be used directly for road paving or sent to asphalt plants for refining.

Request Information

Send your inquiry for further information