Small capacity waste oil distillation machine

Waste Oil Distillation Plant / Date:06-23-2021

Small capacity waste oil distillation machine is used for refining waste oil/crude oil like tire plastic pyrolysis oil, liquid oil sludge, heavy oil, mazut, used engine motor oil, old lubricant oil, etc. to clean yellow diesel. Unique design and outstanding functions can help customer create more profit. This equipment is usually matched with pyrolysis plant. It is widely applied in waste oil management and regeneration industry.

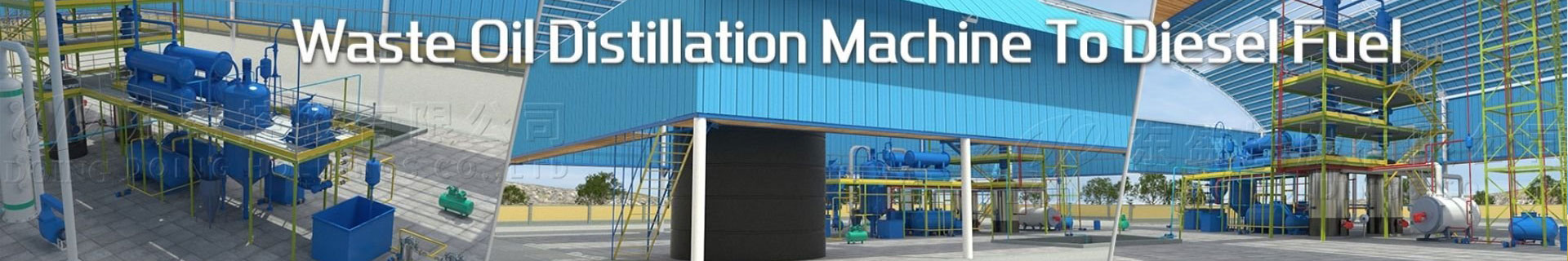

Waste oil distillation machine 3D picture of DOING Company

Waste oil distillation machine 3D picture of DOING Company

The working principle of small capacity waste oil distillation machine

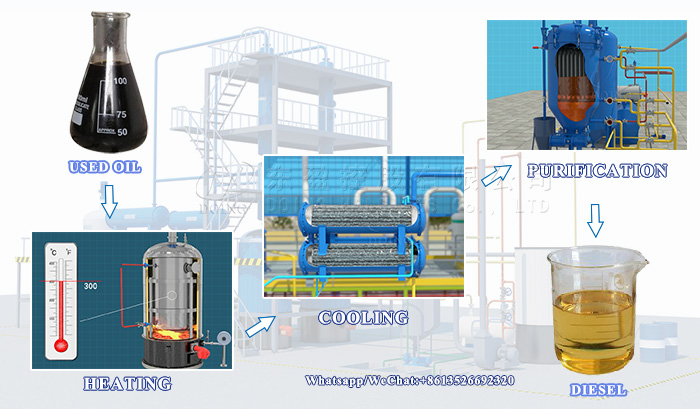

1. Pump raw material into distillation reactor by oil pump. Then close the feeding inlet to totally sealed. (Continuous plant adopts automatic feeding device);

2. Use coal/wood/natural gas/fuel oil/electricity to heat the reactor, and the liquid oil will slowly become oil gas, which will be liquefied into fuel oil by the cooling pipe and condensers and then go into oil tank. For getting higher quality diesel, you are required to control the temperature over 150 Celsius degrees. When the temperature decreases to below 150 Celsius degrees, the gasoline will be cooled out;

3. Some gases like Methane, Ethane, Propane, Butane cannot be liquefied will be recycled into the furnace for heating the reactor;

4. It will produce some smoke when fuel materials are burnt. The smoke will be processed by dedusting system completely;

5. The exhaust gas will go into the chimney sucked by draft fan, before emission the exhaust gas will become steam, no pollution.

Waste oil distillation machine working process

Waste oil distillation machine working process

The unique advantages of small capacity waste oil distillation machine

Safety:

Safety is the most important factor in the whole process. We had successfully researched some safety devices which ensure waste oil distillation machine work safely.

1. Safety valves, alarming device and the pressure gauge etc.

2. We also have oil-water separator which can stop the oil gas recycle to the reactor, which could avoid the accident.

3. High degree of automation: feed the waste oil, crude oil automatically, to pump oil automatically.

Energy saving:

1. Well sealing for heating system, no gas leak and saving fuel.

2. Continuous feeding with automatic feeder, no gas leak.

3. Recycling of exhaust gas and scientific fire channel design can save energy and thereby reducing costs.

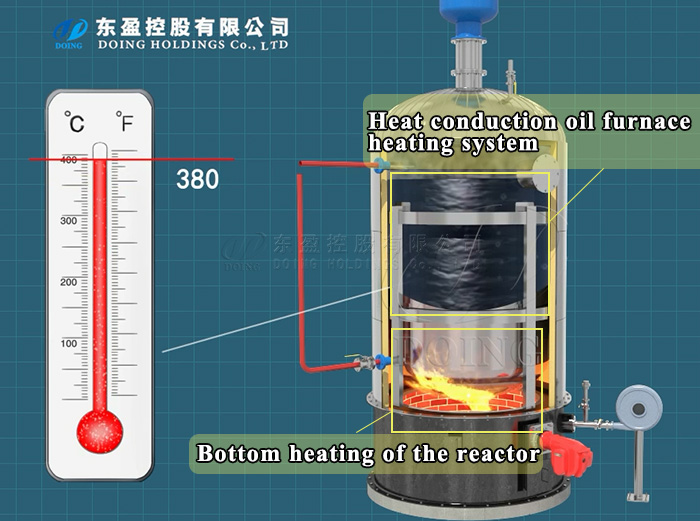

Double heating system

Double heating system

Environmental friendly:

1. The whole process is all sealed, won’t release any gas harmful to human and environment.

2. Well water dedusting system can avoid black smoke.

Desulfuriztion & purification tower

Desulfuriztion & purification tower

Technical parameter of small capacity waste oil distillation machine

| Items | Contents |

| Model | DY-100/500kg, DY-1t, DY-5t, DY-10t, DY-15t… |

| Raw material | Used motor oil, waste tire pyrolysis oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 80-90% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

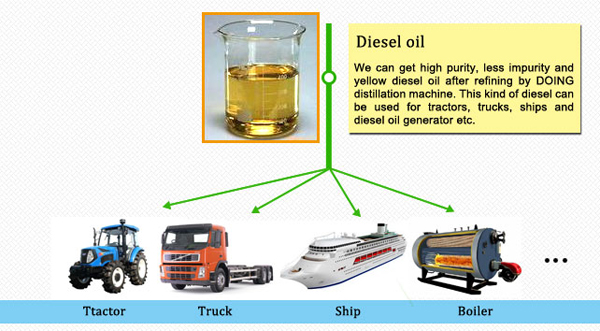

Diesel oil application:

The end diesel product could be directly used instead of normal diesel in many area, like used in heavy machinery, farm machinery and generators, or directly used as clean heating fuel in many industries.

Diesel application extracted from small scale waste oil distillation machine

Diesel application extracted from small scale waste oil distillation machine

Waste oil distillation machine are widely used in transferring waste oil into diesel. The raw materials can be waste fuel oil, waste engine oil, crude oil, lubricant oil, etc. This is a sunrise project, which turn waste into energy.