Tyre Pyrolysis Oil to Diesel Distillation Plant

Waste Oil Distillation Plant / Date:10-30-2020

Tyre pyrolysis oil to diesel distillation plant is used to convert waste tyre pyrolysis oil, waste plastic pyrolysis oil, waste engine oil and waste lubricating oil into non-standard diesel oil and asphalt through distillation/refining technology. DOING tyre pyrolysis oil to diesel distillation plant including vertical distillation reactor, condensers, oil tanks, water seal device, catalytic reactors, boiler, conduction oil tank, dedusting system, chimney, control cabinet.etc. It can convert tyre pyrolysis oil (or other waste oil) into diesel oil without any pollution, which can pass the environmental impact assessment easily.

Tyre pyrolysis oil to diesel distillation plant

Tyre pyrolysis oil to diesel distillation plant

The process of tyre pyrolysis oil to diesel distillation plant

The workflow chart of tyre pyrolysis oil to diesel distillation plant

The workflow chart of tyre pyrolysis oil to diesel distillation plant

1. Pump tyre pyrolysis oil (or other waste oil) into the vertical reactor of the tyre pyrolysis oil to diesel distillation plant.

2. Heat the vertical reactor of tyre pyrolysis oil to diesel distillation plant with heat conduction oil heating together with the bottom fuel heating. When reaching a certain temperature, the oil gas will be vaporized out and separated from the impurities.

3. The oil gas will be cooled into liquid oil by the condensers, and the liquid oil will be collected into the distillate storage tank.

4. The non-condensing oil gas after passing the distillate tank and water seal device will be recycled to heat the reactor of tyre pyrolysis oil to diesel distillation plant.

5. Adding clay into the liquid oil can make the color of oil more bright and transparent. After filtering, the qualified diesel oil will be collected into the oil tank.

6. Collect the asphalt from the vertical reactor.

The advantages of tyre pyrolysis oil to diesel distillation plant

1. The high-speed heating technology can make the distillation process more efficient, shorter in time and less in fuel.

Fast heating system of tire pyrolysis oil distillation plant

Fast heating system of tire pyrolysis oil distillation plant

2. The design of vertical reactor can realize asphalt automatic discharging, which is convenient and quick.

3. The circulating water cooling system consumes almost no water.

4. The diesel oil cleaning system will enable you to get high-quality diesel oil.

5. The efficiency is high, and the diesel oil yield is as high as 90%.

6. Figured with exhaust gas treatment equipment, the whole process of tyre pyrolysis oil to diesel distillation plant is environmentally friendly, and there is no waste pollution.

Our DOING company has different capacities tyre pyrolysis oil to diesel distillation plants from 5T to 20T. Also, we can customize the tyre pyrolysis oil to diesel distillation plant according to your needs.

| Items | Contents |

| capacity | DY-5T, DY-10T, DY-15T, DY-20T |

| Raw material | Plastic/tire pyrolysis oil, waste engine oil |

| Structural form | Vertical |

| outputs | Diesel, asphalt |

| Diesel yield | 80%-85% |

| Operating pressure | Normal |

| Material of reactor | 4 different materials of reactor |

| Thickness of reactor | 16mm |

| Safety standard | Pressure vessel standard |

| Total power | 24.5kw |

| Mode of cooling | Recycled water cooling |

| Required water | 40m³for recycle use |

| Heating method | Conduction oil and fuel heating |

| Discharge way | automatically |

| Noise DB(A) | ≤85 |

| Running system | Semi-continuous |

| Delivery time | 25days |

| weight | 20-50T(depends on the capacity) |

The products and their applications of tyre pyrolysis oil to diesel distillation plant

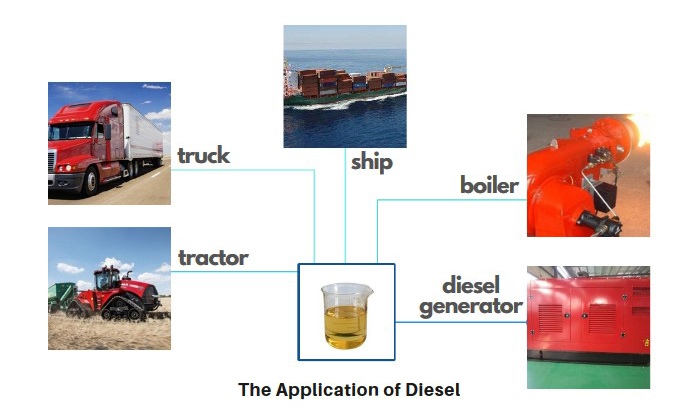

There are two main products of tyre pyrolysis oil to diesel distillation plant, one is non-standard diesel oil, and the other is asphalt. Moreover, these two products both have a wide range of applications.

The non-standard diesel oil obtained from our tyre pyrolysis oil to diesel distillation plant can be directly used in tractors, trucks, ships, boilers, diesel generators, etc.

The application of non-standard diesel oil

The application of non-standard diesel oil

The asphalt is often used for paving, but it can also be further refined by asphalt plant to get fuel oil.

The application of asphalt

Tyre pyrolysis oil to diesel distillation plant offers a new approach to the application of (or other waste oil) by refining it into diesel oil. And diesel oil is a good substitute for oil resources. Tyre pyrolysis oil to diesel distillation plant can help us realize the recycling of resources, thus optimizing the resource structure. So it is a great way to save resources and energy for our world, while, at the same time, reaping a huge profit.

5tpd wase tire pyrolysis oil distillation plant profit analysis

5tpd wase tire pyrolysis oil distillation plant profit analysis

Our Doing company is a professional enterprise with more than decades of years' experience in tyre pyrolysis oil to diesel distillation plant and we can provide one-stop service for production, installation, commissioning, training workers and after-sales. If you have any interest in tyre pyrolysis oil to diesel distillation plant, please contact us, and our project manager will provide you with a customized solution.