Tyre pyrolysis plant cost

Tyre pyrolysis plant

Tyre pyrolysis plant

When starting a tyre pyrolysis business to make money, you must take the cost into account. Generally speaking, the cost of the tyre pyrolysis plant is determined by several factors. They are the following:

1) Machine cost

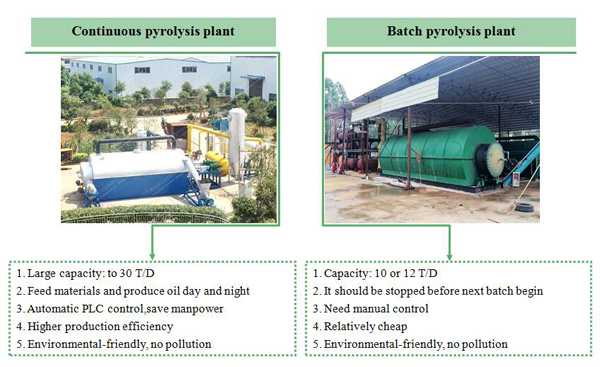

About the machine cost, firstly I want to introduce that the 2 types pyrolysis plant we have.

One is btach type tyre pyrolysis plant, the capacity is from 100kg per batch to 10ton per batch.

The other one is fully continuous tyre pyrolysis plant, the capacity is from 10T/D to 100T/D.

About the machine cost, it’s different depends on different configurations.

Features of continuous and batch tyre pyrolysis plant

Features of continuous and batch tyre pyrolysis plant

2) Installation cost

In order to save the installation cost for customers, we have developed a new design of the machine to make it into frameset. This way, the machine no need much installation works in customer’s factory.

3) Land & construction cost

Firstly, land cost is mainly decided by the installation size of the machine.

And the tire pyrolysis plant no need much construction cost, only need to build a roof to keep the machine out from wind and rain is ok.

DOING waste tyre pyrolysis plant project in Mexico

DOING waste tyre pyrolysis plant project in Mexico

4) Operation cost

About the operation cost of the machine, it’s mainly about the power consumption and worker’s salary.

Technical parameter of tyre pyrolysis plant cost technical data

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyre | Waste tyre | Waste tyre |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Prepared by customer about tyre pyrolysis plant cost

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |

Tyre pyrolysis plant cost final product application

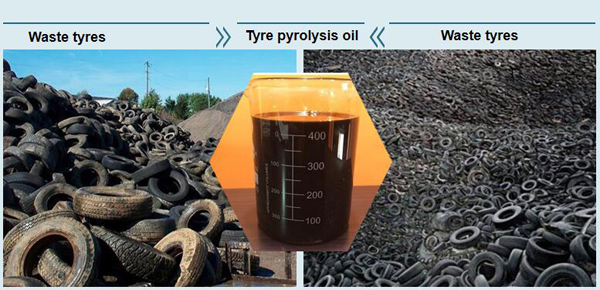

Fuel oil (40% to 45%) The main oil product produced by our recycling application is the fuel oil that is wide used for industrial and commercial purposes. The oil has 40% to 45% of the amount of recycled scrap tyres, which will be carried with licensed tanker trucks.

Fuel oil application

Fuel oil application

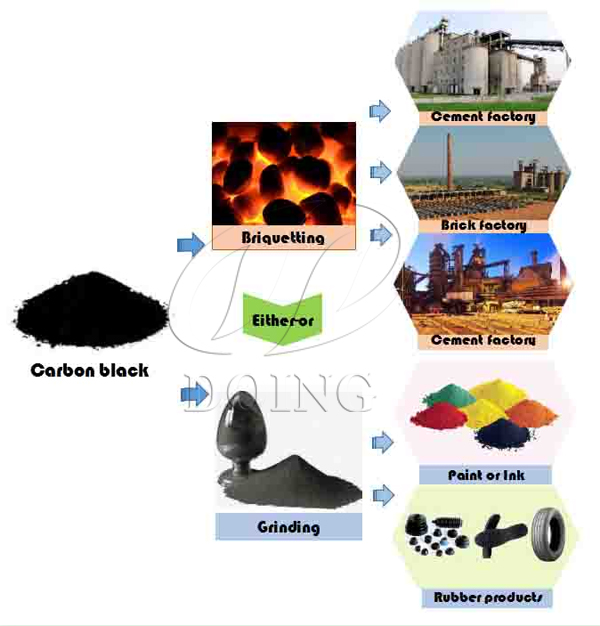

Carbon black (30% to 35%)

Carbon Black is the main product recycled by Pyrolysis technology. The amount of recycled carbon black is 30% to 35% (depending on the type of tyres) of the total amount of scrap tyres recycled in the system. Carbon black is used as raw material or main ingredient in many industries and the chemical structure of carbon black strengthens, lengthens the endurance, and improves the coloring features of the materials.

Carbon black application

Carbon black application

Carbon black produced by Pyrolysis process (CBp) is more economical compared to carbon black produced primarily from petroleum and is more price-efficient to be used as an ingredient in the industries listed;

* Electric cable jacketing

* Conveyor band

* Carrier Bands

* Hose and doormat

* Black nylon bag

* Rubber additive

* Automotive spare parts

* Heat isolation

* Black colorant in rubber materials

* Plastic pipes

* Industrial rubber products

* Fire fighting

Steel wire (10% to 15%)

Tyres contain steel wires and the amount range of 10% to 15% of the total tyre wastage. All of the steel present in the tyre can be detached after pyrolysis recycling process in completed. Valuable steel wires are pressed and sold to steel and scrap dealers.

Gas (10% to 12%)

Non-Condensable gases arise during the pyrolysis process.

Some advantages such as…..

* It has higher calorific value as compared to Natural Gas.

* It can be replaced where Natural Gas and Propane are stored.

* The high energy gas may be utilized as a source of energy for the Pyrolysis process.

* The amount of gas generated in the system is 12% to 15% of the total amount of recycled tyres and considering the 10 ton scrap tyre/day recycling capacity, the facility generates 1200-1500 m3/day gas, which has an enormous energy potential when evaluated.

Request Information

Send your inquiry for further information