Turning waste plastic shopping bag to diesel fuel oil

Turning waste plastic shopping bag to diesel fuel oil

The turning waste plastic shopping bag to diesel fuel oil can reduce the volumes of the waste products and help human protect the environment. And the plastic has been one of the most common materials since the beginning of 20th century because of its durability, low cost and light weight. Plastic makes up around 30% of all rubbish collected. This includes plastic bottles, containers, plastic wrap, packaging, electronic goods, car body parts, etc. Because the plastic is slow to degrade, this kind of waste becomes a problem for many people.

Turning waste plastic shopping bag to diesel fuel oil working process

Turning waste plastic shopping bag to diesel fuel oil working process

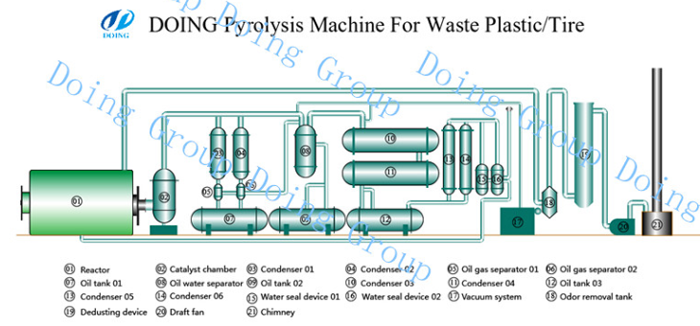

2. The liquid oil will be cooled by condenser from oil gas and then collected by oil tank. Third, the exhaust gas which can not be cooled in normal pressure will be recycled to heat the reactor. In this way, you can not only saving energy, but also protecting environment.

3. Smoke produced by processing the tyres/plastics can achieve national emission standard through dual desulfurization and dusting removal device.

4. After you get oil, the temperature will be low, at this time, carbon black will be discharged automatically.

After all these steps, you can start another batch.

Turning waste plastic shopping bag to diesel fuel oil feature

Turning waste plastic shopping bag to diesel fuel oil feature

1. Safety.

We have some safe devices such as the pressure gauge, alarming ring, safety valve. at the same time we have the anti-back fire device which can avoid the fire back into the reactor.

2. Environment protecting.

If you come to visit our company to see the running plant, you cannot even see the vapor. as we have the dust removal device and dust removal pool.

3. Energy saving.

Our anti-back fire device can collect the exhaust gases which can be fuels after the oil is out so is very convenient and you can save the energy .at the same time, we have the catalyst

chamber which can reduce the temperature of the catalytic prolysis of the tires and plastics. so you can save lot's of energy. except this ,we have vacuum device which let the reactor be negative pressure. So you can image.

4. High degree of automatic.

We have many automatically devices such as: auto-feeder, carbon black elevator, oil pumping automatic, reducing pressure automatic.

Turning waste plastic shopping bag to diesel fuel oil working time:

Here we take 10ton capacity for your reference:

→ Use auto feeder load compete tires into reactor directly, 2 hours

→ Put wood/coal/natural gas/fuel oil into fire furnace make fire, warm up reactor, last 3-4hours

→ After that oil gas will come out, last 10-12hours

→ Cooling down reactor, 1 hour

→ Discharge carbon black, 1 hour

Oil yield rate from waste plastic:

PVC material with very little oil, not good

PE 95%

PP 90%

PS 90%

ABS 40%

Pure white plastic cloth 70%

Plastic package 40%

Plastic logo 20%

Paper coating dry material 60%, wet 15%-20%

Household garbage 30% - 50%

Pure plastic cable covers 80%

Clean plastic bag more than 50%

Technical data of turning waste plastic shopping bag to diesel fuel oil

| Technical parameter of turning waste plastic shopping bag to diesel fuel oil | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about turning waste plastic shopping bag to diesel fuel oil | ||

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |

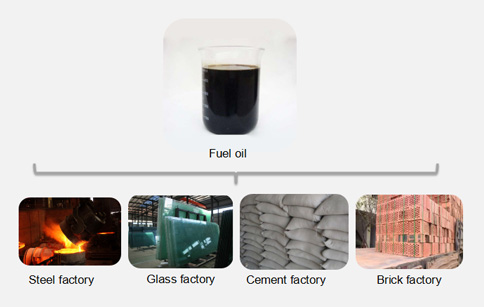

Fuel oil application genearaged by turning waste plastic shopping bag to diesel fuel oil

1. Fuel oil (45%-52%): Oil from turning waste plastic shopping bag to diesel fuel oil can be used as industrial fuel for burning.

Fuel oil application

is crude. You can sell it to the brick factory as internal combustion or to the factory which need it as raw materials, such as shoe, tire, cable and sealant companies. Second, could make further process, make carbon black powder into carbon black briquette, and use it for burning.

Carbon black application

Request Information

Send your inquiry for further information