No Pollution Waste Tyre Pyrolysis Plant

Waste Tire Pyrolysis Plant / Date:03-17-2021

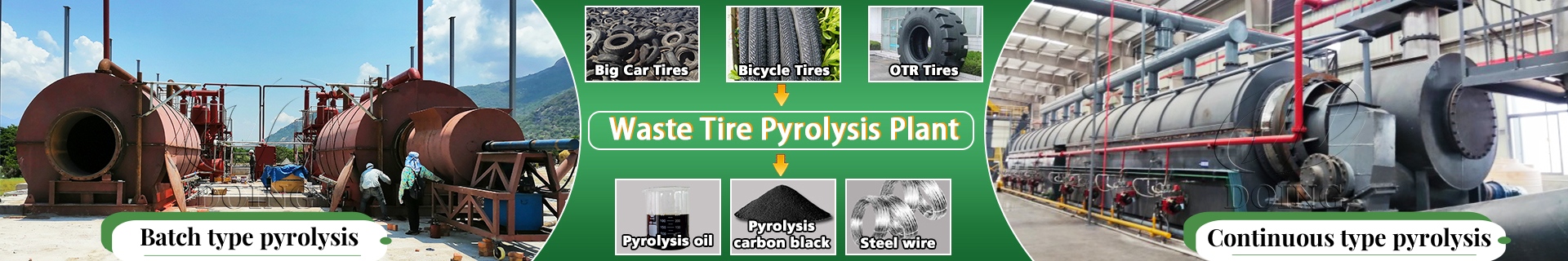

No pollution waste tire pyrolysis plant is a kind of waste recycling machine, which is used to convert waste tires into fuel oil, carbon black and steel wires. Doing Group has two types of no pollution waste tire pyrolysis plant, one is batch waste tire pyrolysis plant, which is cost-effective and easy operation, the other is continuous waste tire pyrolysis plant, which is fully automatic operation, labor saving higher efficient, and higher oil yield. Both of them are environmentally friendly and available to choose with various different capacities according to your requirement.

No pollution waste tyre pyrolysis plant

No pollution waste tyre pyrolysis plant

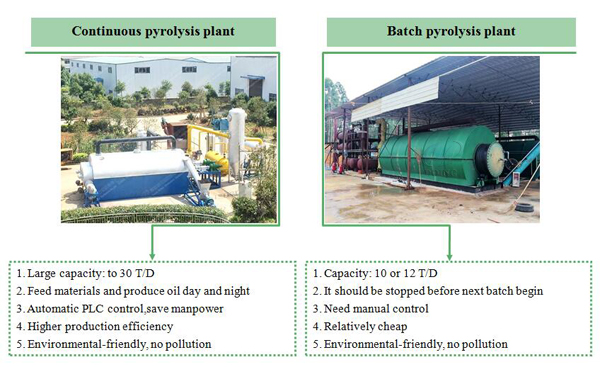

Main differences between the batch waste tyre pyrolysis plant and fully automatic waste tyre pyrolysis plant:

(1) For the continuous system, the feeding of the raw materials and discharging of slag are both automatic, while for the batching system, the two processes are both manual.

(2) For the continuous system, the feeding hole is very small, so it needs shredder to cut the tyres into small pieces (30-50 mm), while the batching system does not need the pretreatment device.

(3) The continuous system can work continuously without a stop, while for the batching system, the reactor must be cooled before the second batch.

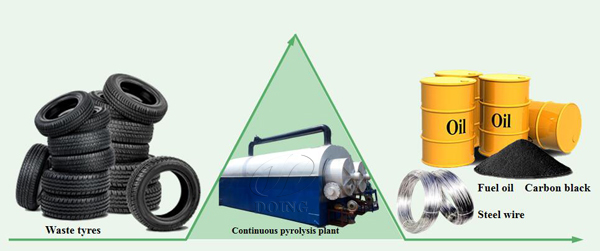

Differences batch and continuous pyrolysis plant

Differences batch and continuous pyrolysis plant

The advantages of no pollution fully automatic waste tyre pyrolysis plant:

• 1. High automation with low labour cost

No pollution fully automatic waste tyre pyrolysis plantis controled by PLC system with automatic feeding and discharge system, which only need 1-2 worker for operating the PLC or computer is ok.

• 2. High oil output

No pollution fully automatic waste tyre pyrolysis plant adopts mutiple reactor design which can make fully pyrolysis of waste tires, thus to get high oil output.

• 3. Big capacity

Also due to continuous feeding and discharge system, and unique mutiple reactor design, our fully automatic continuous waste tyre pyrolysis plant can process at least 10 tons waste tires per day, up to 100T/D.

• 4. Internal rotating for conitnuous operation

For external rotating system, you have to change the sealing material every three days, thus cannot achieve the real sense of continuous process. But our continuous waste tyre pyrolysis reactor adopts internal rotating method, which no need to worry about the sealing of the external rotating system.

• 5. Long service life

During the continuous pyrolysis process, reactor heating is by indirect hot air heating, which will not damage reactor so much, thus to keep long usage life of the reactors. And since the hard steel wire already removed from waste tires before pyrolysis processs, thus no damage for the reactor.

The technical data of no pollution fully automatic waste tyre pyrolysis plant:

| Item | Specifications | ||||||

| Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| Working type | Continuous | ||||||

| Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| Rotating | Internal rotating | ||||||

| Cooling system | Recycled waster cooling | ||||||

| Reactor material | Q245R/Q345R boiler plate | ||||||

| Heating method | Indireact hot air heating | ||||||

| Heating fuel | Fuel oil/gas | ||||||

| Feedstock | Waste tire/plastic/rubber | ||||||

| Output | Fuel oil, carbon black | ||||||

The technical data of no pollution batch waste tyre pyrolysis plant:

| Items | Contents | ||

| Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| Day Capacity | 6 ton | 8 ton | 10 ton |

| Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| Structural form | Horizontal rotation | ||

| Operating pressure | Normal | ||

| Material of pyrolysis Reactor | Q245R | ||

| Thickness of pyrolysis Reactor | 16mm | ||

| Rotate speed of pyrolysis Reactor | 0.4turn/minute | ||

| Size of Reactor(D×L) | 2200*6000-2800*6600 | ||

| Total power | 19KW | ||

| Mode of cooling | Water cooling | ||

| Cooling area of condenser | 100sqm | ||

| Kind of transmission | Internal gear drive | ||

| Noise dB(A) | ≤85 | ||

| Weight | 27T-35T | ||

| Working form | Intermittent operation | ||

| Delivery time | 20days | ||

| Land area | 35m*15m | ||

| Labor | 3-4 workers | ||

| Density of oil | 0.89g/cm3 | ||

| Combustion value | 44.30KJ/KG | ||

The final product and application of no pollution waste tyre pyrolysis plant:

By using no pollution waste tyre pyrolysis plant, you can get tyre oil, carbon black and steel wire from waste tyres. The tyre oil can be widely used as fuel oil in industries such as steel and iron and boiler factories, ceramics, power or chemical industries or hotels, restaurants etc., or used for generators to get electricity. The carbon black can be used for construction bricks with clay or used as fuel. The steel wire can be recycled to produce new steel products. Besides, some combustible gas generated can be recycled to the reactor and act as fuel, which will save energy for the whole process.

| NO | Name | Percentage | Usage |

| 1 | Tyre fuel oil | 45% |

1.Can be sold directly 2.Can be as fuel 3.Can be used industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic factory. |

| 2 | Carbon black | 30% |

1.Can be sold directly 2.Can be used electric cable jacketing,black nylon bag,rubber additive |

| 3 | Steel wire | 15% |

1.Can be sold directly 2.Make steel bloom by use hydraulic press-packing |

| 4 | Oil gas | 10% |

1.Can be as fuel burn by use gas burning system 2.Extra gas also be storage as fuel for other heating |