Is there small continuous scale pyrolysis plant? How does it work?

Industry News / Date:January 8, 2020

We have continuous pyrolysis plant with different processing capacity from 20 tons to 50 tons per day. Small continuous scale pyrolysis plant refers to 20TPD continuous pyrolysis plant. It is fully automatic and controlled by PLC system, which can achieve automatic feeding, automatic slag discharge, at the same time, it can improve productivity and save labor. Therefore small continuous scale pyrolysis plant is more popular with customers in developed countries in Europe and America.

DOING small continuous scale pyrolysis plant project site

DOING small continuous scale pyrolysis plant project site

The functions of small continuous scale pyrolysis plant is to extract oil and carbon black from waste plastic and waste tires. So how does the small continuous scale pyrolysis plant work? You can browse the 3D running video below to learn about the process step by step.

As shown in the video, the running process of small continuous scale pyrolysis plant includes 7 steps: raw material pretreatment, automatic feeding, cracking process, automatic carbon black discharge, oil gas cooling process, syn gas purification, and smoke dust removal.

1. Raw material pretreatment

To ensure the continuity of feeding, it need to pretreat raw material, such as tire, it need to be drawn out steel wire first and then broken into small pieces in case of jam during operation.

2. Automatic feeding

In order to ensure the sealing of the entire system, small continuous scale pyrolysis plant uses a spiral feeding system with oil and material seals.

3. Cracking process

Heating the reactor to a certain temperature, the raw materials are continuously pushed through the spiral scraper in the reactor, and at the same time, the oil and gas are continuously cracked out.

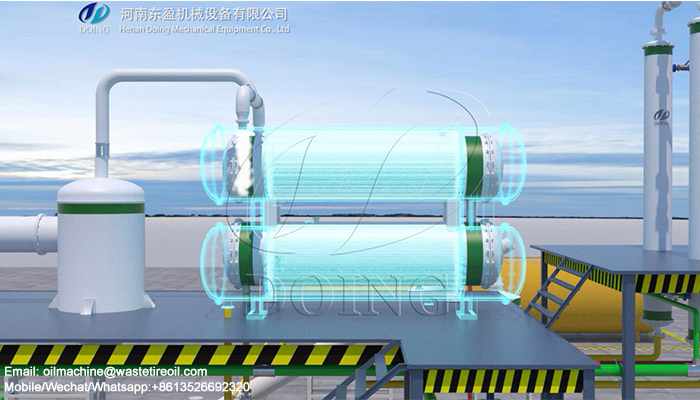

small continuous scale pyrolysis reactor

4. Automatic carbon black discharge

There are two pipelines at the carbon discharge site, one is to discharge the oil and gas upwards, and the other is to discharge the carbon black downwards. The carbon black is discharged through the spiral slag discharge system to ensure that the carbon black is automatically and continuously discharged.

5. Oil gas cooling process

Small continuous scale pyrolysis plant uses the professional tube condenser system, which can fully ensure that all oil gas can be cooled to liquid pyrolysis oil.

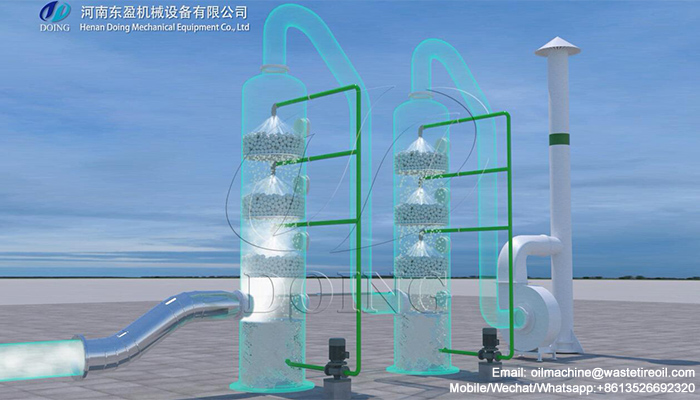

Tube condenser system for higher cooling efficiency

Tube condenser system for higher cooling efficiency

6. Syn gas purification

Before the syn gas is recycled to heat the reactor, the syn gas purification system is used to remove harmful gases such as hydrogen sulfide, which can control the generation of bad odor.

7. Smoke dust removal

The smoke generated by heating fuel passes through the smoke dust removal device, which can remove dust and harmful gases to meet environmental protection standards.

Our smoke dust removal device

Our smoke dust removal device

Small continuous scale pyrolysis plant is designed for customers who want to improve efficiency and productivity while saving labor and plant space. If you have less than 20 tons waste plastic or waste tires to process, our batch tyre pyrolysis plant can meet your needs, the capacity is from 100kg to 15 tons. For more details, please feel free to contact us.

Request Information

Send your inquiry for further information