Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>What is pyrolysis machine? What raw material can be recycled by pyrolysis machine?

Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>What is pyrolysis machine? What raw material can be recycled by pyrolysis machine?

What is pyrolysis machine? What raw material can be recycled by pyrolysis machine?

Waste Tire/Plastic Pyrolysis Plant / Date:January 30, 2023

Pyrolysis machine, also called pyrolysis plant/pyrolysis unit/pyrolysis device, is a popular waste treatment recycling machine that can recycle and convert solid&hazardous waste like rubber tires, scrap plastic, oil sludge, biomass, coal tar oil residue, aluminum plastic composite materials, plastic medical waste, e-waste(like PCB), etc. into valuable products namely pyrolysis oil, syn-gas and char(carbon black), biochar, aluminum ingot, etc.

DOING company pyrolysis machine for waste treatment and recycling

DOING company pyrolysis machine for waste treatment and recycling

1. Q: What are the key components of pyrolysis machine?

A: The key components of DOING Pyrolysis Plant are as follows:

①Waste Pre-teatment system: such as waste tyre shredder, rubber tires cutting machine, scrap plastic grinding machine, biomass wood crushing machine, biomass pellet machine, etc.

②Waste Feeding system: different feeding systems, we support munual feeding, auto-feeder and continuous feeding ways.

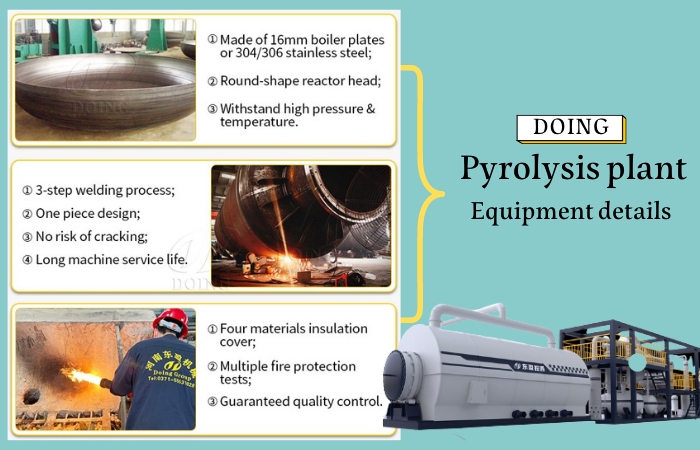

③Pyrolysis reactor system: made of different boiler plate and other 304/3016 steel materials, the thickness of pyrolysis reactor can be customized from 14-22mm. And the inner structure of DOING pyrolysis reactors may have different designs, for example, for oil sludge thermal pyrolysi streatment, we have anti-coking devices for reaction vessels.For example, for sludge treatment, we have anti-coking devices for reaction tanks.

DOING pyrolysis reactor design details

DOING pyrolysis reactor design details

For example, for sludge treatment, we have anti-coking devices for reaction tanks.

④Oil gas condensation system: there are both multiple-stage shell tube condensation systems and waste tank condensation systems to choose from, both of them has good oil cooling effect to ensure high oil yield.

⑤Pyrolysis residue discharge system: We are equipped with different unloading equipment for different pyrolysis products, such as carbon black lifting devices, carbon black sealing systems, wire drawing equipment, etc.

⑥Exhausted gas purification system: DOING pyrolysis machine is equipped with exhaust gas purification devices, desulfurization and denitrification towers and dust removal devices to ensure the control of particulate matter, sulfur dioxide, nitrogen oxides, and volatile organic compounds, and to guarantee strict compliance with emission standards, even those of European Union countries;

2. Q: What is the common/typical output of pyrolysis machine?

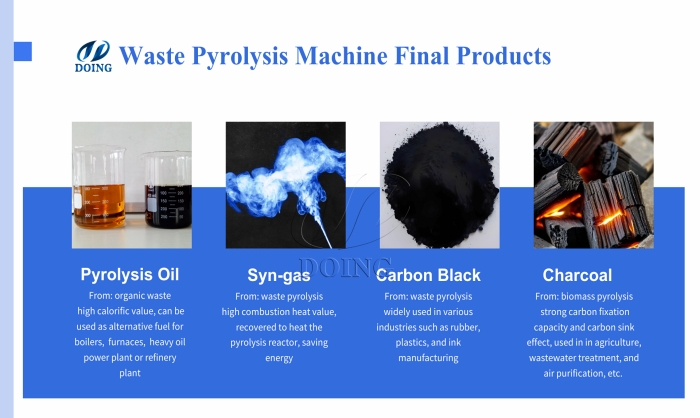

A: The output depends largely on inputs in terms of quality and types of waste raw materials and the pyrolysis technology which has been used to process the waste. The final products outputs of pyrolysis plant are mainly:

The output rate and applications of final products from pyrolysis machine

①Pyrolysis Oil ≈ 30 to 85%

(The tire pyrolysis oil yield is about 35-52%,the plastic pyrolysis oil output is between 30% and 95%.)

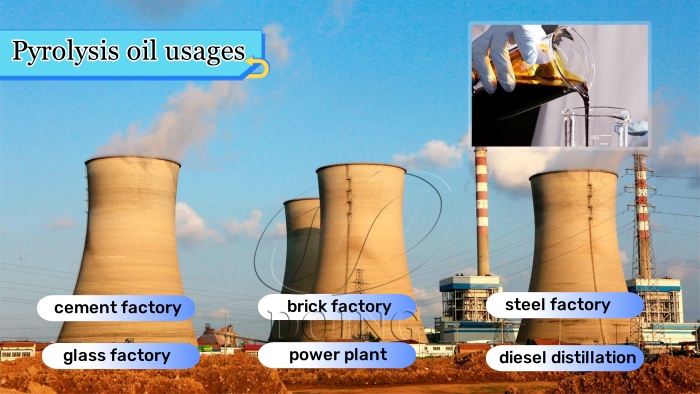

Pyrolysis oil is an important liquid product generated during the waste pyrolysis process, with a calorific value typically ranging from 42000 to 46000 kilojoules per kilogram, which is close to or exceeds the calorific value of some traditional fuels. pyrolysis oil can serve as an efficient energy substitute and is widely used in the industrial sector, especially for the combustion of heavy oil power plant, boilers, or heating furnaces.

Compared to conventional fossil fuels, cracked oil has lower production costs and, due to its source from waste, the production process can effectively reduce carbon emissions, which meets current environmental policy requirements. In the chemical industry, pyrolysis oil can be further converted into various chemicals as raw materials, or used as raw materials for heavy oil /waste oil refineries to extract higher quality fuel resources, such as non-standard diesel, thereby further improving the economic benefits of waste pyrolysis projects.

Waste regenerated pyrolysis fuel oil applications

Waste regenerated pyrolysis fuel oil applications

②Pyrolysis gas ≈ 17 to 35%

Pyrolysis gas (mainly composed of methane, ethylene, propylene, etc.) has a high combustion heat value. Its advantage is that pyrolysis gas can be recycled for heating reaction vessels, replacing external energy supply, thereby significantly reducing the energy cost of pyrolysis plant projects. Through this approach, not only has energy efficiency been improved, but also a significant amount of operating costs have been saved for the enterprise.

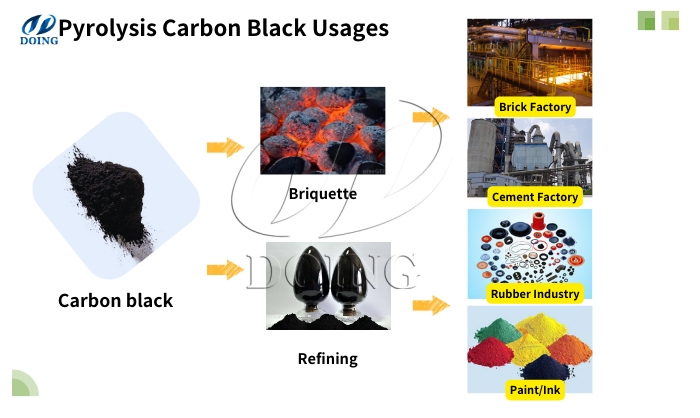

③Pyrolysis residue, mainly carbon black ≈ 3 to 25%

(The content may increase when there is ash content in the feedstock.)

Carbon black is an important solid product in the pyrolysis process, and its unique conductivity, wear resistance, and reinforcement properties make it widely used in various industries. Especially in the rubber industry, carbon black can improve the wear resistance and aging resistance of tires, and improve the service life of products. In the plastic, ink, and coating industries, carbon black can enhance the coloring power and weather resistance of products, and is widely used in fields such as automotive, electronics, and building materials. With the continuous improvement of global environmental requirements, the market demand for carbon black continues to grow, and its high added value makes it an important source of profit in waste pyrolysis projects.

Recovered pyrolysis carbon black applications

Recovered pyrolysis carbon black applications

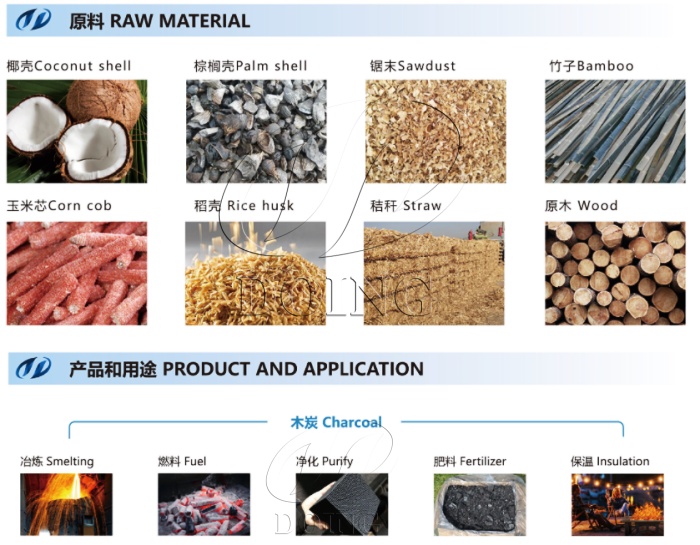

④Charcoal/Biochar ≈ 30 to 35%

Charcoal/Biochar is a carbon based material obtained by pyrolysis agricultural and forest waste such as wood, bamboo, coconut shells, and rice bran. It has significant carbon fixation capacity and can convert these biomass wastes into stable carbon assets, effectively reducing carbon footprint. In agriculture, biochar can improve soil structure, enhance soil water retention, permeability, and fertility, increase crop yield and drought resistance, and is an environmentally friendly soil amendment. In addition, the use of biochar also has a significant carbon sink effect, reducing carbon dioxide emissions through long-term carbon storage, and is an important means of addressing climate change.

With the promotion of the concept of green and sustainable development, the application of biochar in agriculture, horticulture, wastewater treatment, and air purification has gradually expanded, becoming an indispensable green product in biomass wastes pyrolysis projects.

Biomass to biochar pyrolysis machine feedstocks and product applications

Biomass to biochar pyrolysis machine feedstocks and product applications

3. Q: What are processing capacities of DOING Pyrolysis Machine?

A: Different types of pyrolysis machines have different processing capacities. We can customize the pyrolysis machines from 100kg to 50+ tons per day, etc.

| Profit analysis(10TPD waste tyre pyrolysis plant) | |

| Cost/Day | |

| Waste Tyre | 10T*30USD/T =300USD |

| Electricity Consumption | 30 USD |

| Heating fuel(tire oil) | 0.4T*500USD/T=200USD |

| Manpower | 3 Workers* 50USD = 150USD |

| Income/Day | |

| Fuel Oil | 4T* 500USD/T = 2000USD |

| Carbon Black | 3T * 50USD/T=150USD |

| Steel Wires | 1.5T* 215USD/T = 322.5 USD |

| Profit | 1792.5USD |

4. Q: What are the types of pyrolysis machine? How to select a suitable pyrolysis machine?

A: According to the process operation types and designs, there are mainly four types of pyrolysis machines that Henan DOING Company can supply and customize for you:

Four types waste tyre/plastics/oil sludge/biomass pyrolysis plant

Four types waste tyre/plastics/oil sludge/biomass pyrolysis plant

①Fully Continuous type pyrolysis machine: 15-50tpd capacity, PLC automatic control, 24/7hours continuous feeding and discharging, suitable for the buyers who have a big budget and the needs of big processing capacity, high automatic degree.

②Semi-Continuous type pyrolysis machine: 10-20tpd daily processing volume, continuous feeding and high temperature dicharging, especially suitable for buyers who want to process granular or crushed waste, such as waste plastic pellets, waste rubber, wood chips or Semi-flow/Semi-liquid sludge.

③Batch type pyrolysis machine: 1-18tpd capacity per batch, the cost effective and popular choice of most pyrolysis machine buyers.

④ Small mobile skid-mounted design type pyrolysis machine: 100kg/500kg per batch, suitable for buyers who have a small budget or who need a mini/small scale pyrolysis machine for trial/piolet running and science research.

You can select suitable pyrolysis machines based on your needs. If you have doubts, our sales manager can recommend you suitale pyrolysis machine solutions.

5. Pyrolysis Machine Running Video

The processing process of pyrolysis machine are mainly feeding---pyrolysis---cooling---discharging---purification. About the details, welcome to click the video to watch it.

6. How many countries has DOING Company installed pyrolysis machines in?

As a world-leading pyrolysis machine manufacturer, Henan Doing Company has exported and installed the pyrolysis machines in more than 100+ countries and regions around the world, such as India, Uganda, UAE, Bangladesh, Spain, Italy, USA, Vietnam, Thailand, Indonesia, South Korea, United Kingdom, Australia, Fiji, Russia, Mexico, Brazil, Botswana, Chile, Ukraine, etc. Our high quality and cost-efficient pyrolysis machines have received many good feedbacks from our customers. Our pyrolysis machine can meet the environment proection and installation requiements of different countries.

For more details of pyrolysis machines project cases, please click: Waste Pyrolysis Machine Installed By DOING.

Request Information

Send your inquiry for further information