Plastic to fuel oil recycling process plant

Plastic to fuel oil recycling process plant is an industry that converts waste plastic & tires & rubber and other waste materials into Pyrolysis Oil, Carbon Black & Hydrocarbon Gas.

Plastc to fuel oil recycling prcess plant

The Plastic to fuel oil recycling process plant can reduce the volumes of the waste products and help human protect the environment. And the plastic has been one of the most common materials since the beginning of 20th century because of its durability, low cost and light weight. Plastic makes up around 30% of all rubbish collected.

This includes plastic bottles, containers, plastic wrap, packaging, electronic goods, car body parts, etc. Because the plastic is slow to degrade, this kind of waste becomes a problem for many people. As we all know, plastics are not only pollute the lands, waterways and oceans, but also affect the marine animals and humans, leading to the metabolic disturbance. So, solving the plastic pollution has become the imminent thing and is the primary task for people. The best method to handle the waste is to turn waste into wealth and recycle the resources.

Plastic to fuel oil recycling process plant

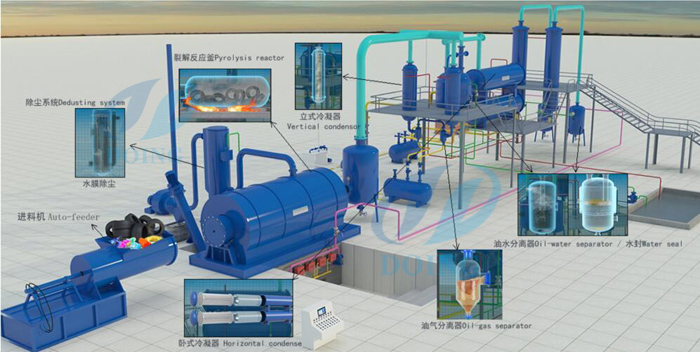

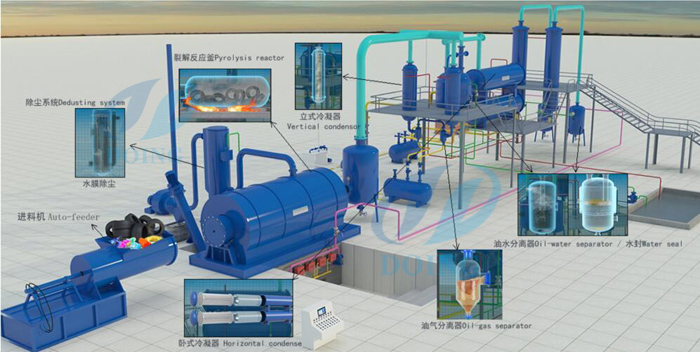

First of all, waste plastic needs to be broken and dried; Then pretreated waste plastic will be conveyed to the moving horizontal plastic pyrolysis reactor through feeder system, it starts to pyrolysis and oil gas will be generated when temperature up to 500 degrees. Then the oil gas will be cooling down by spray cooling system, it would be liquefied, go into the oil tank. And at the same time, some un-condensed gas comes into hot air circulation heating system by secondary fire retardant damper, it will be recycled for heating reactor as gas material. Exhaust gas will go to the strong spray de-dusting system for removing pollution, then let environmental gas go to the air. The pyrolysis slag emissions and recycled through second sealed discharging system.

Pyrolysis oil (Fuel oil – 40 to 45%)

Fuel oil application

The essential product of Plastic to fuel oil recycling process plantreferred as fuel oil (40 to 45 % of total quantity feed) which is used as a fuel component for heating in fire chamber.