How to extraction copper from copper wire stripping machine?

Auxiliary Equipment / Date:August 26, 2017

Copper wire stripping machine

The whole production line has unique structure, big process capacity and low power consumption. With high separation rate, the separation is conducted by several parts. This copper wire stripping machine has not only improved the purity of copper, but also reduced the pollution to the environment.

How to extraction copper from copper wire stripping machine?

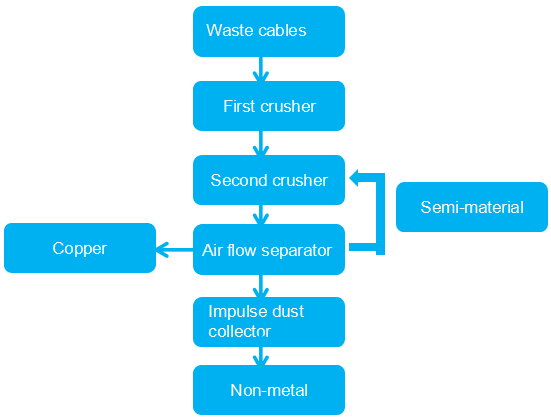

Wire stripping machine working process

Please make sure waste wire stripping machine and another equipments are in good condition. Then start the machine, and keep the machine running unloaded for 5-10 minutes before feeding.

Attention:

Boot sequence: suction fan1→suction fan 2→blower-feeding blower →riddler→mainframe.

Shutdown sequence: Riddler→blower→suction fan1→suction fan

2→feeding blower→mainframe

2. Feeding

Before feeding, pick up the debris especially the iron from the wires in case of the damage to the crusher blades. During the feeding period, the feeding speed should be in accordance with the crushing speed.

3. Fine crushing

If there is any abnormal noise, please stop and check the crusher, or change different size screen.

If there is too much copper or the produced particles are relatively small during the production process, replace the screen and adjust the distance between the fixed knife and the moving one.

If the machine is easy to overheat, stop the device and inspect the gearing.

4.Vibrating separator

After crushed, the mixed material will be delivered to vibrating device. The copper from vibrating separator is complete copper without plastic, while the copper clad from the opposite discharging hole needs the second crushing.

Request Information

Send your inquiry for further information