DOING's pyrolysis plant and distillation plant projects in Malaysia

In Asia / Date:December 3, 2021

Henan Doing Mechanical Equipment Co., Ltd is a professional company specialized in manufacturing waste tire, plastic and oil sludge recycling machine in China. Till now we have successfully installed hundreds of pyrolysis plants in more than 90 different countries all over the world, and Malaysia is one of the best-selling countries for our machines.

1. What are the pyrolysis plant and distillation plant project cases that Henan Doing Company has done in Malaysia?

As one of the earliest waste tire, plastic and oil sludge recycling machine manufacturing company involved in international business, as early as 2012, DOING’s pyrolysis plant and distillation plant began to enter the Malaysian market. So far, our company has successfully helped customers in many regions in Malaysia to install the waste tire, plastic and oil sludge recycling plant, such as Klang, Kuching, Penang, Fleur City, etc.

Malaysia's pyrolysis and distillation plant project cases installed by DOING

Malaysia's pyrolysis and distillation plant project cases installed by DOING

And here we are pleased to share some waste tire, plastic or oil sludge recycling plants project cases details, hoping to help our customers know more about setting up waste tire, plastic and oil sludge recycling plants in Malaysia.

▶Project case 1: Malaysia 12tpd waste tire pyrolysis plant project in 2013

In 2013, a customer from Malaysia ordered a 12tpd waste tire pyrolysis plant from DOING Group. The purpose he bought our machine is to dispose of waste tires to get pyrolysis oil, carbon black and steel wire to make money.

Malaysia 12tpd waste tire pyrolysis plant project in 2013

Malaysia 12tpd waste tire pyrolysis plant project in 2013

This customer had done detailed market analysis and was well versed in Malaysian policy. He shared with us that the Malaysian government has provided tax exemption support to enterprises that dispose of waste tires in an environmentally friendly manner, and tires are free of charge. We are still in touch, and his waste tire recycling plant is also developing well.

▶Project case 2: Malaysia 2 sets waste tire pyrolysis plant project in 2014

Malaysia 2 sets waste tire pyrolysis plant project in 2014

Malaysia 2 sets waste tire pyrolysis plant project in 2014

In 2014, Indian customers bought 2 sets of waste tire pyrolysis plant from Henan Doing Group. This project was eventually built in Malaysia . The purpose of the customer bought new waste tire pyrolysis plant is to replace the existing bad equipment to make more money.

Indian customers bought these old pyrolysis plants from one small factory three years ago, but the quality of them are so poor. After many many times’ repair, he gave up and decided to buy new machines. Due to this customer has rich experience in repairing pyrolysis machines, he knows the pyrolysis plant very well. And he knows how to choose a good quality machine. After a long time comparing with other pyrolysis equipment suppliers, he finally decided to buy equipment from Doing Group.

▶ Project case 3: Malaysia 5tpd waste engine oil to diesel distillation plant project in 2019

Malaysia 5tpd waste engine oil to diesel distillation plant project in 2019

Malaysia 5tpd waste engine oil to diesel distillation plant project in 2019

In 2019, a government official in Malaysia contacted us to purchase waste engine oil to diesel distillation machine. He collected a lot of waste engine oil and wanted to convert the waste engine oil into diesel. He appointed an engineer who knew the technology very well to contact us. And after a period of discussion, both sides determined the final distillation project solution.

He gave us feedback that when the distillation plant was officially put into operation, the obtained diesel oil was clean and bright in color. In order to further confirm the quality of the oil, he even took the oil to the laboratory for an oil product test. According to the test result, the quality of diesel oil obtained by the customer was very high, and the customer was so happy and satisfied. Recently, this customer contacted us and expressed their hope to expand the scale of the factory and to continue their friendly cooperation with us.

▶Project case 4: Malaysia 10tpd waste tire pyrolysis plant project in 2019

Soon later in 2019, July, one of our customers contacted us via internet,he is a very professional engineer. He has been responsible for the installation and operation of many government projects, and they were all running smoothly. After visited our fatory,he was very satisfied with our pyrolysis plant technology also we discussed together with the technology. Finally, he decided to buy one set 10tpd waste tire pyrolysis plant.

Malaysia 10tpd waste tire pyrolysis plant project in 2019

Malaysia 10tpd waste tire pyrolysis plant project in 2019

Unlike previous projects, this time he did this project by himself. After confirming the configuration, he signed with us an agreement to be independent install the machines. More information about this project , pls contact us at any time.

▶Project case 5: Malaysia, Penang 10tpd new type waste tire pyrolysis plant and 5tpd waste oil distillation plant project in 2020

At the end of 2019, a Malaysian customer purchased one set 10TPD new type pyrolysis plant and one set 5tpd newest design distillation plant. This customer was originally in a trading business. In early 2019, he accompanied his customers to visit our factory to learn about the equipment needed for pyrolysis business and the detailed pyrolysis process. During the visit, he was impressed by the advanced technology of our equipment and the strong strength of our company. So after a detailed feasibility study and analysis, he immediately went to China to sign an equipment purchase contract with us.

At present, this project has not been finished installation. For more specific information about this project, please continue to pay attention to us.

Malaysia Penang 5tpd waste oil distillation plant project in 2020

Malaysia Penang 5tpd waste oil distillation plant project in 2020

The project cases that Henan Doing Company has installed in Malaysia are far more than those mentioned above. The above project information is for your reference only.

▶Project case 6:2 sets of 10TPD oil sludge treatment pyrolysis plants in Malaysia

We have installed two sets of semi-continuous oil sludge pyrolysis units in Malaysia, each with a daily processing capacity of 10 tons. The semi-continuous oil sludge thermal desorption unit uses automatic feeding andhigh-temperature slag discharge, enabling efficient recovery of oil from oily contaminants. Through treatment by this environmentally friendly pyrolysis equipment, we can not only recover fuel resources but alsoensure that the treated oil sludge meets landfill standards. Here is the operation video of oil sludge treatment pyrolysis plants in Malaysia:

2.What are the unique advantages to develop pyrolysis and distillation plant in Malaysia?

There are so many people invest in waste tire, waste plastics pyrolysis plants and waste oil distillation plants in Malaysia, because Malaysia has some unique advantages.

①Advantage 1: Abundant raw materials

There are a lot of waste tire and plastic and waste oils resources in Malaysia, these waste resources need to be solved urgently.

Waste tire/plastic and used egine oil

Waste tire/plastic and used egine oil

②Advantage 2:Broad sales market

Malaysia has a complete range of local industries, petrochemicals, electric power, mining, metallurgy and manufacturing are relatively developed, so there is a wide range of oil use, and the oil sales market is not worried.

③Advantage 3:National policy support

Malaysian government issued many policies that attach great importance to waste recycling and rubber utilization.

3.How profitable it is to start pyrolysis and distillation plant business in Malaysia?

The purpose of all investors doing business is to earn more money, this is beyond doubt. To let customers know how profitable it is to start pyrolysis and distillation plant business in Malaysia, here let’s take the 10T/D pyrolysis machine as example to analyze it for you.

| Profitability Analysis For 10t Waste Tyre Pyrolysis Machine | |

| Cost | |

| Waste Tyre | 10t * 80 USD/t = 800 USD |

| Electricity Consumption | 20 USD |

| Manpower | 3 persons * 10 USD = 30 USD |

| Revenue | |

| Fuel Oil | 4t * 400 USD/t = 1600 USD |

| Carbon Black | 3t * 30 USD/t = 90 USD |

| Steel Wires | 1.5t * 200 USD/t = 300 USD |

| Profit | 1140 USD |

4.Why buy pyrolysis and distillation equipment from DOING?

If you also want to invest in related businesses, please contact DOING company to purchase pyrolysis or distillation equipment. DOING company has the following equipment advantages and after-sales service advantages, which is beneficial to maximize your benefits.

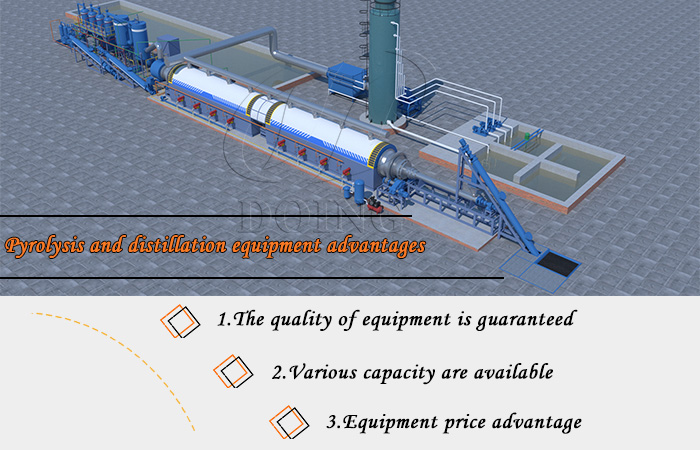

①Pyrolysis and distillation equipment advantages

Pyrolysis and distillation equipment advantages

Pyrolysis and distillation equipment advantages

A.The quality of equipment is guaranteed:

Doing pyrolysis equipment’s reactor uses an arc-shaped head. The arc-shaped head has the function of buffering pressure, which can ensure the long service life of equipment. And it uses a shell tube condensing system, shell tube condensing system can ensure the cooling effect, improve the oil output rate and oil quality.

B.Various capacity are available:

DOING has different scales and different automation types pyrolysis or distillation equipment to choose from, which can meet the needs of different customers. All equipment is customized through our independent factory to ensure the equipment quality while reducing the customer's investment cost.

C.Equipment price advantage:

Doing Company not only has professional R&D team to customize suitable equipment for customers, but also has specialized and independent factory to finish equipment manufacturing. In addition, our company has many years of cooperation with suppliers of stainless steel, valves, pumps and other production materials. We can get the production materials at the factory price. All these can ensure that people can buy equipment at relatively low prices.

②After-sales service advantages

After-sales service advantages of DOING

After-sales service advantages of DOING

A.Equipment delivery advantages:

DOING will pack all the small spare parts with wooden cases and attach the spare parts list to every wooden case for customer checking when receive the equipment. We also could help our customer to book the ship if customer don't have suitable agent for shipping, we have long term cooperation forwarder who can find the cheapest ship for our customers. And they are familiar with loading our equipment, which is beneficial to ensure the safety of equipment.

B.Equipment installation advantages :

We have many experienced overseas installation engineers. When the equipment arrives in the customer's country, we can send engineers to install, debug and run the equipment, and train the customer's workers to operate and run the equipment. Moreover, we have a special Chinese and English version of the after-sales installation manual, which introduces the detailed steps of equipment operation and maintenance in detail. Workers can refer to this installation manual at any time when operating the equipment to avoid mistakes. We will also provide one year after-sales warranty service, and provide lifetime technical support for customers.

C.Comprehensive technical support:

DOING's engineer team can not only provide customers with technical plan drawings, on the other hand, it can also help customers survey the factory buildings and design layout drawings, equipment basic condition diagram, etc.

It has always been the pursuit of DOING company to let the machine quality, manufacturing strength and customers’ feedback become the best publicity. If you want to start waste tire, plastic or oil sludge recycling plant, please don’t hesitate to contact us. Not only can we customize suitable machine for you, but also share our project installation experience to help you develop recycling business smoothly!

5.What's the business scope of Doing Group? What products can Doing Company provide?

Henan Doing Environmental Protection Technology Co., Ltd is a comprehensive environmental equipment manufacturer integrating technological design, research and development, machine production, sales and after-sales service in one.

DOING Group mainly supplies the following waste recycling to fuel oil energy plants:

●Batch type waste tire/plastic/rubber/oil sludge pyrolysis plant;

●Semi-continuous type waste tire/plastic/rubber/oil sludge pyrolysis plant;

● Fully continuous waste tire/plastic pyrolysis plant;

●Waste engine oil/pyrolysis oil/old motor oil/mazut oil to diesel refinery distillation plant;

●Pyrolysis plant auxiliary equipment, such as environmental protection devices, tire plastic shredding machine, oil sludge dewatering equipment;

Whenever you want to know more about Malaysia pyrolysis plant and distillation plant, welcome to send us an inquiry! We will provide you the most suitable project solutions according to your specific requirements for free.

Request Information

Send your inquiry for further information