Home > Project Case > In Africa>Waste pyrolysis and distillation plant projects installed by DOING in Egypt

Home > Project Case > In Africa>Waste pyrolysis and distillation plant projects installed by DOING in Egypt

Waste pyrolysis and distillation plant projects installed by DOING in Egypt

In Africa / Date:December 6, 2021

In the past 10 years, DOING GROUP has exported waste tires/plastic pyrolysis and waste oil distillation machines to more than 90 countries and regions. Among them, Egypt is one of our most mature markets, and DOING's machines occupies most of the waste tires/plastic pyrolysis and waste oil distillation market in Egypt!

1.What are the pyrolysis plant and distillation plant project cases that Henan Doing Company has done in Egypt?

It is believed that most Egyptian customers will not be unfamiliar with the waste tires/plastic pyrolysis and waste oil distillation machines manufacturer DOING GROUP of China when conducting feasibility studies and analysis related to waste tires/plastic pyrolysis or waste oil distillation plant projects. DOING has helped many customers successfully install the related projects in Cairo, Alexandria and other places in Egypt.

Waste tire/plastic pyrolysis and waste oil distillation plant installed by DOING In Egypt

Waste tire/plastic pyrolysis and waste oil distillation plant installed by DOING In Egypt

The following are some waste tires/plastic pyrolysis and waste oil distillation plant project cases installed by DOING for your reference.

▶ Project 1: 10TPD waste tire pyrolysis plants in Egypt

In July 2013, one of our Egyptian customers purchased a set of 10TPD waste tire pyrolysis machine and an additional set of carbon black grinding machine from DOING. In addition to pyrolysis oil, he also wants to deep process carbon black products to achieve more benefits.

10TPD waste tire pyrolysis plants was installed in Egypt

10TPD waste tire pyrolysis plants was installed in Egypt

He commissioned his Chinese friends to help select the professional waste tire pyrolysis machine manufacturers, and the machine’s pyrolysis technology and quality should be guaranteed. After careful selection, his friend contacted DOING and signed an order with us.

According to the feedback, our pyrolysis machine runs very well after installation, and our customers are very satisfied. The customer makes full use of the pyrolysis oil as a fuel, and he also ground the carbon black to 325 mesh, which made considerable profit locally.

Later, he wanted to expand the pyrolysis plant scale, and purchased another set of waste tire pyrolysis machine again from DOING.

▶ Project 2: two sets 10TPD pyrolysis plants in Egypt

Two sets 10TPD waste recycling pyrolysis plants in Egypt

Two sets 10TPD waste recycling pyrolysis plants in Egypt

In 2014, an Egyptian customer purchased two sets of 10TPD pyrolysis machines from DOING. This customer did a very sufficient feasibility investigation and analysis before investing in the pyrolysis business. He is full of confidence in the substantial profits that can be brought by pyrolysis business.

Therefore, in order to maximize profits, he compared the pyrolysis machine designs and after-sales service of different manufacturers in detail, and finally selected DOING and directly came to China to sign the contract. And in 2014, our professional engineer went to the customer's pyrolysis plant site to assist in the installation and commissioning of these two sets of pyrolysis machines. The entire installation process only took one month, and then the pyrolysis machines were put into operation!

▶ Project 3: waste tire pyrolysis machine in Egypt

By July 2015, the installation work of our Egyptian customer’s waste tire pyrolysis machine was completed. This Egyptian customer is a professional engineer himself, and he came up with the idea of investing in the waste tire pyrolysis business during his work.

Before purchasing waste tire pyrolysis machine, he inspected the waste tire pyrolysis business for more than half a year. He also visited other pyrolysis machine manufacturers in China, but he finally bought the pyrolysis equipment of our factory after careful consideration.

This customer is very satisfied with our machine quality and complete after-sales, and now we are still in good contact, he has even become one of our overseas engineers.

Waste tire pyrolysis machine in Egypt

Waste tire pyrolysis machine in Egypt

▶ Project 4: waste medical plastic treatment pyrolysis machine and small pyrolysis oil distillation unit in Egypt

This project is an order from an Egyptian client for a 15-ton waste plastic treatment pyrolysis machine. The equipment is primarily used to environmentally recycle and process medical plastic waste, especially discarded PP and PE infusion sets, syringes, and plastic packaging. In addition to this plastic waste, our equipment can also process aluminum-plastic composite pharmaceutical blister pack waste, yielding fuel oil and aluminum. Besides the plastic pyrolysis machine, our Egyptian customer also ordered a set of 500kg small scale pyrolysis oil distillation unit, which is of small processing capacity and skid-mounted design(easy for transportation and fast installation).

Waste plastic pyrolysis distillation machines order in Egypt

Waste plastic pyrolysis distillation machines order in Egypt

These cases are only part of the waste tires/scrap plastic pyrolysis and waste oil distillation plant projects installed by DOING. If you want to get more information about the project cases, or more equipment installation pictures and running videos, please contact us, our business manager will share with you in detail.

2. Is it profitable to invest in waste tires/plastic pyrolysis plant and waste oil distillation plant projects in Egypt?

The answer is yes. Egypt is a good market for waste tires/plastic pyrolysis plant and waste oil distillation plant projects because of its abundant waste tires/plastics raw materials and widely uses of obtained products. In order to give you a more intuitive understanding of the profits of pyrolysis business or waste oil refining business, DOING takes the Egyptian customer hot purchase equipment, 10TPD waste tire pyrolysis machine, as an example to show you the profit analysis table.

| Profitability Analysis For 10t Waste Tyre Pyrolysis Machine | |

| Cost | |

| Waste Tyre | 10t * 80 USD/t = 800 USD |

| Electricity Consumption | 20 USD |

| Manpower | 3 persons * 10 USD = 30 USD |

| Revenue | |

| Fuel Oil | 4t * 400 USD/t = 1600 USD |

| Carbon Black | 3t * 30 USD/t = 90 USD |

| Steel Wires | 1.5t * 200 USD/t = 300 USD |

| Profit | 1140 USD |

3.Why buy pyrolysis and distillation machine from DOING?

If you also want to invest in related businesses, please contact DOING company to purchase pyrolysis or distillation machine. DOING company has the following machine advantages and after-sales service advantages, which is beneficial to maximize your benefits.

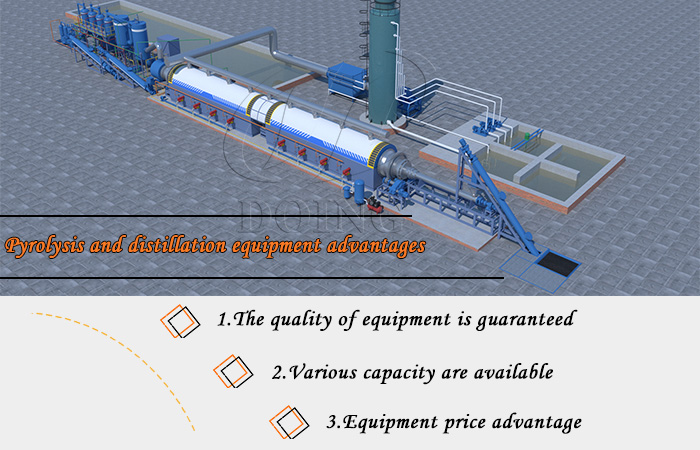

①Pyrolysis and distillation machine advantages

Pyrolysis and distillation machine advantages

Pyrolysis and distillation machine advantages

A.The quality of machine is guaranteed:

Doing pyrolysis machine’s reactor uses an arc-shaped head. The arc-shaped head has the function of buffering pressure, which can ensure the long service life of machine. And it uses a shell tube condensing system, shell tube condensing system can ensure the cooling effect, improve the oil output rate and oil quality.

B.Various capacity are available:

DOING has different scales and different automation types pyrolysis or distillation machine to choose from, which can meet the needs of different customers. All machine is customized through our independent factory to ensure the machine quality while reducing the customer's investment cost.

C.Machine price advantage:

Doing Company not only has professional R&D team to customize suitable machine for customers, but also has specialized and independent factory to finish machine manufacturing. In addition, our company has many years of cooperation with suppliers of stainless steel, valves, pumps and other production materials. We can get the production materials at the factory price. All these can ensure that people can buy machine at relatively low prices.

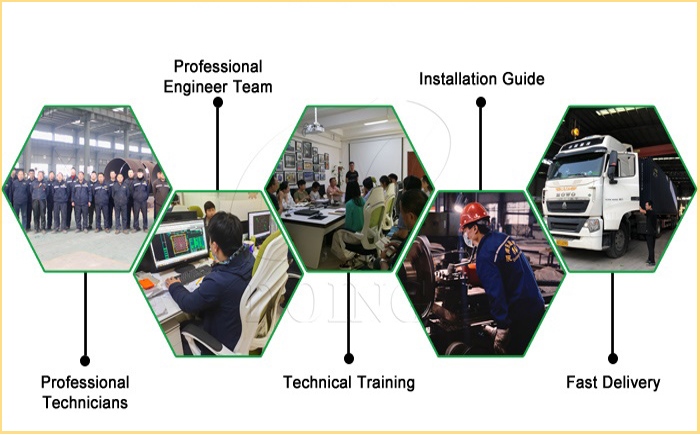

②After-sales service advantages

After-sales service advantages of DOING

After-sales service advantages of DOING

A.Machine delivery advantages:

DOING will pack all the small spare parts with wooden cases and attach the spare parts list to every wooden case for customer checking when receive the machine. We also could help our customer to book the ship if customer don't have suitable agent for shipping, we have long term cooperation forwarder who can find the cheapest ship for our customers. And they are familiar with loading our machine, which is beneficial to ensure the safety of machine.

B.Machine installation advantages :

We have many experienced overseas installation engineers in Egypt. When the machine arrives in the customer's country, we can send engineers to install, debug and run the machine, and train the customer's workers to operate and run the machine. Moreover, we have a special Chinese and English version of the after-sales installation manual, which introduces the detailed steps of machine operation and maintenance in detail. Workers can refer to this installation manual at any time when operating the machine to avoid mistakes. We will also provide one year after-sales warranty service, and provide lifetime technical support for customers.

C.Comprehensive technical support:

DOING's engineer team can not only provide customers with technical plan drawings, on the other hand, it can also help customers survey the factory buildings and design layout drawings, machine basic condition diagram, etc.

It has always been the pursuit of DOING company to let the machine quality, manufacturing strength and customers' feedback become the best publicity. If you want to start waste tires/plastic pyrolysis or waste oil distillation plant, please don't hesitate to contact us. Not only can we customize suitable machine for you, but also share our project installation experience to help you develop recycling business smoothly!

Pyrolysis distillation machine manufacturer DOING Company service

Pyrolysis distillation machine manufacturer DOING Company service

4.What's the business scope of DOING Group? What products can DOING Company provide?

Henan Doing Environmental Protection Technology Co., Ltd is a comprehensive environmental equipment manufacturer integrating technological design, research and development, machine production, sales and after-sales service in one.

Our main business:

● Batch type scrap rubber tyre/scrap plastic/oily sludge recycling pyrolysis equipment;

● Semi-continuous type scrap rubber tyre/scrap plastic/oily sludge treatment pyrolysis machine;

● Fully continuous waste rubber power/used tire/ mixed plastic pyrolysis plant;

● Used engine oil/old motor oil recycling distillation plant;

● Other Pyrolysis Distillation plant auxiliary equipment;

Please don't hesitate to contact us to customize the most suitable machines if you have interests in developing your waste tires/plastic pyrolysis and waste oil distillation plants, and DOING will try our best to help you maximize the profits!

Request Information

Send your inquiry for further information