Waste plastic to oil conversion machine

Waste plastic to oil conversion machine

Which waste plastic can be disposal by waste plastic to oil conversion machine?

Waste plastic to oil conversion machine can application this waste plastic

DOING GROUP with its unique renewable technology has come up with a concept of setting new standard waste plastic to oil conversion machine in renewable energy that includes using of waste tires as a raw material and producing green fuel oil, carbon black, steel and gas. With global warming and utilization of rubber, it has now become necessary to recycle the waste and convert it in fuel oil in such a way that it is environment friendly. This is a unique technology and can change energy market scenario in a big way.

Waste plastic to oil conversion machine advantage

Waste plastic to oil conversion machine advantage

Waste plastic to oil conversion machine advantage

1) Latest generation waste plastic to oil conversion machine

2) Efficient technology.

3) Easy process and easy to operate.

4) More efficient comparatively.

5) High Oil Output recovery

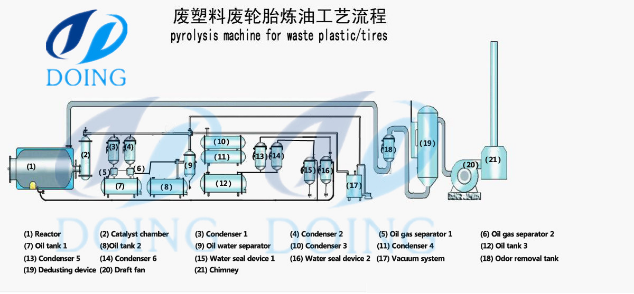

Waste plastic to oil conversion machine working process

Waste plastic to oil conversion machine working process

1. Put raw materials into reactor by auto-feeder, then heat the reactor with any one of the following fuel materials: coal, wood, natural gas, oil. Do not stop heating the reactor, when the temperature reaches nearly 250 degree Celsius, waste tyre will be transferred to oil gas.

2. The liquid oil will be cooled by condenser from oil gas and then collected by oil tank. Third, the exhaust gas which can not be cooled in normal pressure will be recycled to heat the reactor. In this way, you can not only saving energy, but also protecting environment.

3. Smoke produced by processing the tyres/plastics can achieve national emission standard through dual desulfurization and dusting removal device.

4. After you get oil, the temperature will be low, at this time, carbon black will be discharged automatically.

After all these steps, you can start another batch.

Waste plastic to oil conversion machine diferent plastic oil yield

2. The liquid oil will be cooled by condenser from oil gas and then collected by oil tank. Third, the exhaust gas which can not be cooled in normal pressure will be recycled to heat the reactor. In this way, you can not only saving energy, but also protecting environment.

3. Smoke produced by processing the tyres/plastics can achieve national emission standard through dual desulfurization and dusting removal device.

4. After you get oil, the temperature will be low, at this time, carbon black will be discharged automatically.

After all these steps, you can start another batch.

Waste plastic to oil conversion machine diferent plastic oil yield

| PE | 95% |

| PP | 90% |

| PS | 90% |

| ABS | 40% |

| Leftovers of paper/纸厂下脚料 | Wet 15-20%,dry 60% |

| House garbage/生活垃圾 | 35%-50% |

| Plastic cable/塑料电缆 | 80% |

| Plastic bag/塑料袋 | 50% |

| Submarine cable/海底电缆 | 75% |

| Rubber cable /橡胶电缆 | 35% |

| Sole/鞋底 | 30% |

| Big tires/卡车轮胎 | 45%-50% |

| Small tires/轿车轮胎 | 35%-40% |

| PVC | Not suitable/不适合炼油 |

| PET | Not suitable/不适合炼油 |

Waste plastic to oil conversion machine technical data

| Technical parameter of Waste plastic to oil conversion machine | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about Waste plastic to oil conversion machine | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

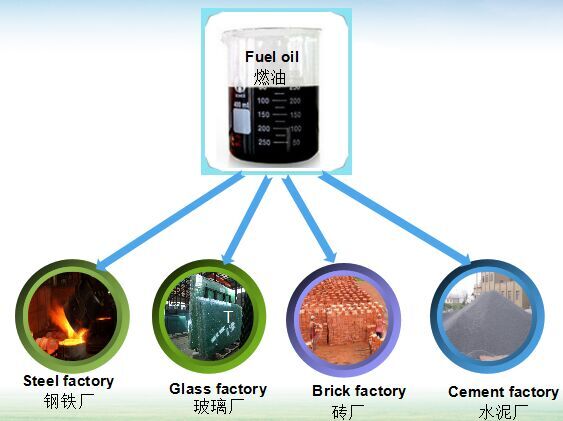

Waste plastic to oil conversion machine application

Fule oil application

Fuel oil

This oil product is a kind of crude fuel oil, which can be used for industrial heating used in any fuel needed industrial factories, such as cement plant, steel mill, glass factory, brick factory, boiler used factory, etc. Or can be refined to diesel, directly used in diesel burners, generators, heavy trucks, agricultural machinery, and mix with normal diesel used for cars.

Carbon black

Carbon black application

Carbon black produced from this waste plastic to oil conversion machine is crude powdery material, which can be directly sold to cement factory mix with cement. Or made into briquettes used for heating, just like coal. Or grinded into fine powder used for making paint and printing ink.

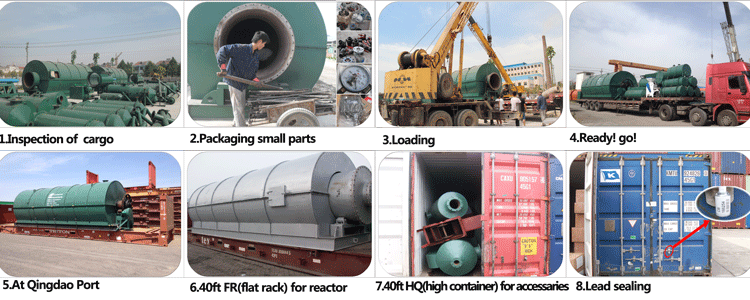

Waste plastic to oil conversion machine delivery

Request Information

Send your inquiry for further information