Waste plastic recycling to fuel oil pyrolysis plant

Plastic has been one of the most common materials since the beginning of 20th century because of its durability, low cost and light weight. Plastic makes up around 30% of all rubbish collected, which includes agricultural mulch/films, paper mill waste, medical injection bags, plastic bottles, containers, plastic wrap, packaging, electronic goods, car body parts, etc. As we all know, waste plastics are not only pollute the lands, waterways and oceans, but also affect the marine animals and humans, leading to the metabolic disturbance. Because the plastic is slow to degrade, this kind of waste becomes a problem for many countries. Today I will recommend a machine that recycles plastic without pollution - waste plastic recycling to fuel oil pyrolysis plant.

Waste plastic recycling to fuel oil plant

Waste plastic recycling to fuel oil plant

Compared to disposing of plastics through landfills or incineration, which causes serious environmental pollution and can lead to fire disasters or the spread of disease, using waste plastic recycling into fuel oil plant is a green way of waste management. Waste plastic recycling to oil plant can convert waste plastic to fuel oil and carbon black environment friendly, which not only solves environmental pollution but also creates wealth.

Henan Doing Company is a leading manufacturer specialized in large, medium and small size waste plastic recycling to fuel oil plant to get fuel oil. The advantages of buying our equipment are as follows:

1. High oil yield: plastic oil 85%-90% for PP, PE, PS, ABS. Almost all of the plastic waste(except PET and PVC) can be recyled by DOING waste plastic pyrolysis plant.

Waste plastic recycling pyrolysis oil yeilds

Waste plastic recycling pyrolysis oil yeilds

2. Delivery time: the delivery time shall be 25days more or less after get the advance payment.

3. Warranty and machine life: We guarantee the complete machine 1 year, the reactor service life can be 6-8 years.

4. The machine Raw material: DOING's plastic to fuel oil pyrolysis plant reactor adopts three-step welding process and manufactures in strict accordance with pressure vessel standards. The reactor is made of Q245R, Q345R boiler plate or 304, 306 stainless steel. The thickness of the entire reactor is 16mm, making the equipment more durable. Reasonable operation and maintenance can appropriately extend its service life.

High quality DOING plastic to fuel oil pyrolysis reactor

High quality DOING plastic to fuel oil pyrolysis reactor

5. The machine installation: as a reliable pyrolysis machine manufacturer with all-around service team, we will send engineer to buyer’s place when getting the plastic to fuel oil recycling machine. The engineer mainly installs the machine and training your workers. Until the machine can running well.

Plastic to fuel oil recycling pyrolysis machine manufacturer services

Plastic to fuel oil recycling pyrolysis machine manufacturer services

Waste plastic recycling to fuel oil plant technical data

| Technical parameter of waste plastic recycling to fuel oil plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Waste plastic recycling to fuel oil plant end products

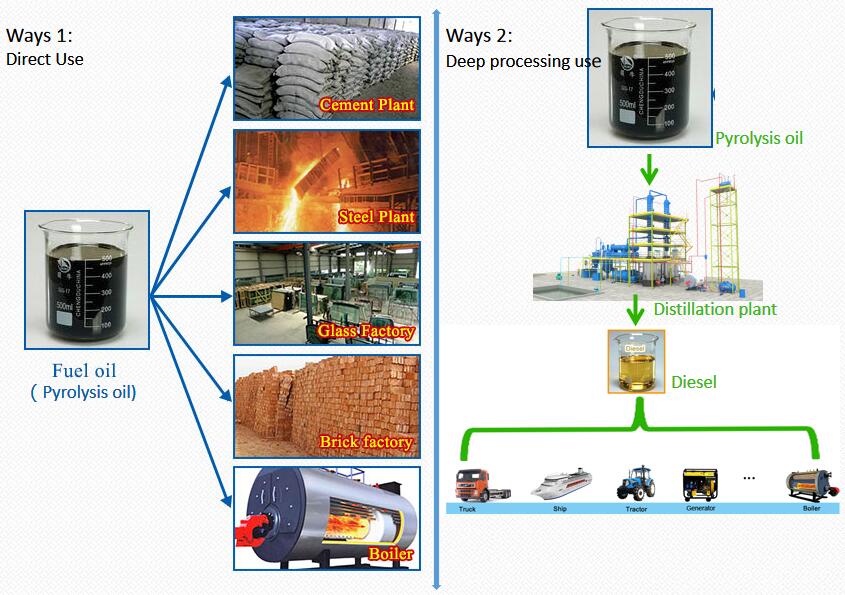

Doing waste plastic recycling to fuel oil plant can convert waste plastic into fuel oil and carbon black. And they can be used in different fields for different purposes.

Fuel oil:

This oil product is a kind of crude fuel oil, which can be used for industrial heating used in any fuel needed industrial factories, such as cement plant, steel mill, glass factory, brick factory, boiler used factory, etc. Or it can be refined to diesel by waste oil distillation plant, which can be directly used in diesel burners, generators, heavy trucks, agricultural machinery, and mix with normal diesel used for cars.

Fuel oil application

Fuel oil application

Carbon black:

Carbon black produced from this waste plastic recycling to fuel oil plant is crude powdery material, which can be directly sold to cement factory mix with cement. Or made into briquettes used for heating, just like coal. Or grinded into fine powder used for making paint and printing ink.

Carbon black application

Carbon black application

Addressing this waste plastic recycling challenge requires innovative, accessible, and effective solutions. Our plastic to fuel oil pyrolysis plant provides a transformative pathway to manage plastic waste responsibly, creating sustainable industries and cleaner environments.

Why DOING Pyrolysis Plant is Ideal for Waste Plastic Recycling:

①Cost-Effective Waste Management: Our technology offers an economically viable alternative to costly landfilling and primitive waste disposal methods, turning a liability into an asset.

Waste plastic recycling to fuel oil pyrolysis plant profit

Waste plastic recycling to fuel oil pyrolysis plant profit

②Environmental Remediation: Help prevent plastic pollution from entering waterways and marine environments, protecting biodiversity and public health.

③On-site Resource Utilization: Recover valuable energy and chemical feedstocks directly at the source of waste generation, reducing reliance on imported fuels and raw materials.

④Multiple Sizes and Types: Our plastic to fuel oil pyrolysis plant running systems are designed for ease of operation and maintenance, making them suitable for diverse technical capabilities and infrastructure levels. Based on different requirements of customers, we designed the machines with different capacities and different operation modes:

Batch continuous plastic recycling prolysis plant for sale

Batch continuous plastic recycling prolysis plant for sale

⑤Contribution to National Environmental Agendas: Support national goals for waste reduction, pollution control, and the development of a green economy.

I'm sure you've learned a little bit about the waste plastic recycling to fuel oil pyrolysis plant from this article. If you are interested in this plant, welcome to contact us. For waste plastic recycling pyrolysis projects, we work with clients from all over the world, such as the United States, India, Indonesia, Brazil, Japan, Germany, the United Kingdom, France, Canada, Australia, Mexico, the Philippines, Vietnam, Egypt, etc. Henan Doing Companywill provide A-Z technical services to help you effectively deal with format waste plastic waste and bring considerable economic benefits to your business.

Request Information

Send your inquiry for further information