Waste plastic

Plastic products has been used widely, and waste plastic can be seen everywhere. It has seriously affected our environment on two aspects, such as visual pollution and potential hazards. Visual pollution means that aesthetic perception on living city affected by scrap plastic in everywhere. Potential hazards mainly refers to degradation-resistant of waste plastic affecting on absorbing of nutrients and water by crop, reducing the production; and otherwise, animals will be die if eats it unconscious. Recycling and utilization of waste plastic is increasingly becoming an important aspect for environmental protection. Advanced design waste plastic disposal machine has supplied a new solution on disposal of waste plastic.

Advanced design waste plastic disposal machine

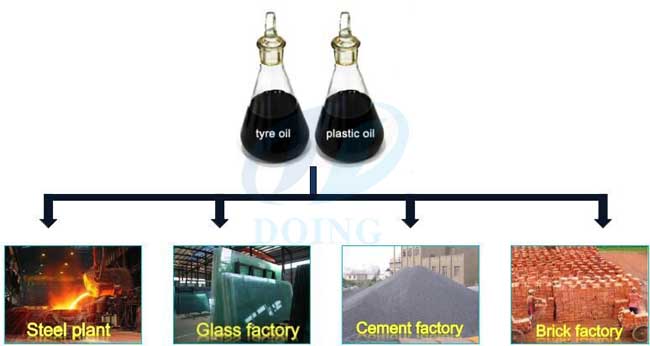

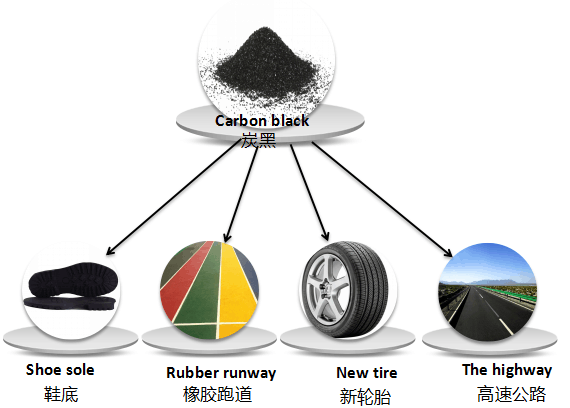

Advanced design waste plastic disposal machine is an industry that converts waste plastic and other waste materials into Pyrolysis Oil, Carbon Black & Hydrocarbon Gas. The advanced design waste plastic disposal machine can reduce the volumes of the waste products and help human protect the environment. And the plastic has been one of the most common materials since the beginning of 20th century because of its durability, low cost and light weight. Plastic makes up around 30% of all rubbish collected. This includes plastic bottles, containers, plastic wrap, packaging, electronic goods, car body parts, etc.

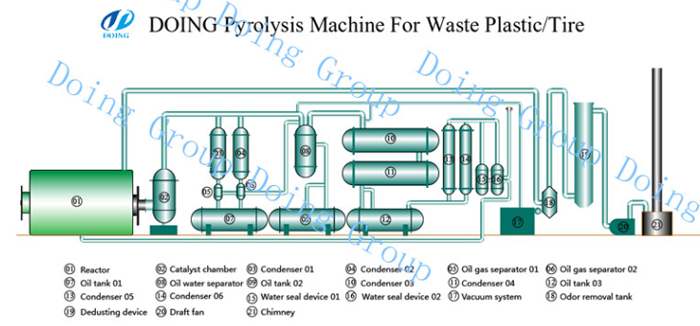

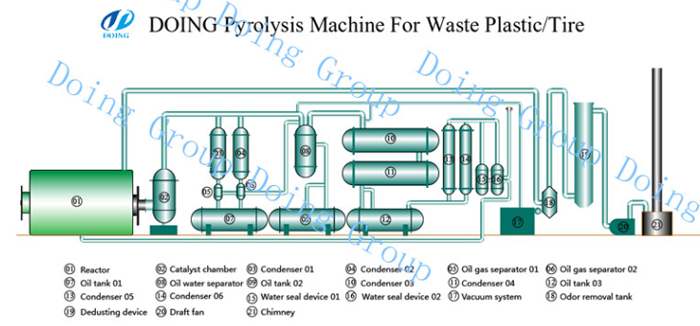

Advanced design waste plastic disposal machine working process

Advanced design waste plastic disposal machine working process

The pyrolysis process and principle of waste plastic disposal machine:

Firstly, put the raw material into furnace

Secondly, burn the fuel material (coal, or wood, or natural gas, or oil) in the combustion system.

After finishing oil producing, the temperature of reactor will come down, at the same time; carbon black will be discharged automatically.

Lastly, when the temperature falls to 100 degree Celsius, worker could open the door of the reactor to discharge the steel wire, and then can start another batch.

Approx oil yield of different raw materials:

Fuel oil from waste plastic

|

PE |

95% |

|

PP |

90% |

|

PS |

90% |

|

ABS |

40% |

|

Leftovers of paper |

Wet 15-20%, dry 60% |

|

House garbage |

35-50% |

|

Plastic cable |

80% |

|

Plastic bag |

50% |

|

Submarine cable |

75% |

|

Rubber cable |

35% |

|

Sole |

30% |

|

Big tires |

45-50% |

|

Small tires |

35-40% |

|

PVC |

Not suitable |

|

PET |

Not suitable |