Plastic to oil

With increasing plastic products consumption, waste plastic is also growing. At present in the world, waste plastic are mainly as plastic film, plastic yarn and fabric, foam, plastic packaging and containers, daily plastic products, plastic bags, agricultural film and so on. Besides, cars plastic, electronic and electrical appliances supporting plastic become one of the important sources of waste plastic after these products scrap. If there is any mistake of the application and post-processing of the storing, transportation and processing of waste plastic, it will damage the environment and harm to people’s health.

Converts waste plastic to oil machine

Converts waste plastic to oil machine

Converts waste plastic to oil is an emerging technology, plastic can be split into oil gas under high temperatures, and then through circulating water cooling system, cooling down oil gas to oil. Through the machine, we can not only processing of plastic waste, but also gaining valuable oil resources. Some people may worry about the second time pollution. Do not worry, our machine is completely sealed, around the machine is tasteless. Machine will produce some exhaust gas, but these gases will recycle to furnace door to heat the machine again. Our machine adopts activated carbon technology to remove bad smell, at the same time, use the water film dust removal system to wash the smoke. Finally to achieve the goal that no pollution to environment.

Converts waste plastic to oil machine working process

Converts waste plastic to oil machine working process

Converts waste plastic to oil machine working process

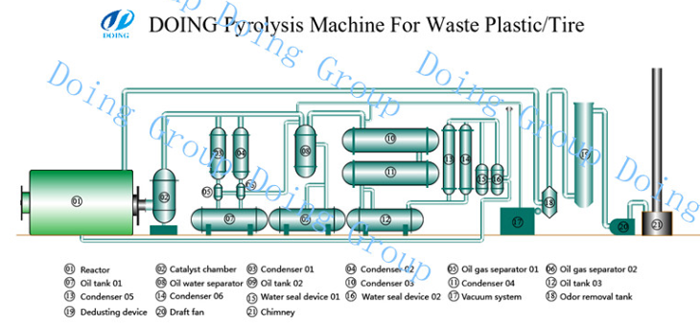

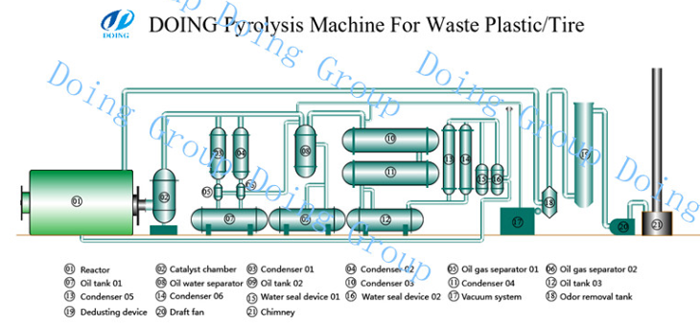

The mixed waste plastics will be shredded and continuously fed into the pyrolysis reactor via feeding machine. The materials will be pre-heated during the conveying process and the low melting point plastic like PVC will be pyrolyst. The HCl will be then neutralized treated after separation with other materials.

→ The constant temperature heating system supplies heat to the pyrolysis reactor. The raw materials are continuously fed into the pyrolysis reactor and spreaded by the system, completing pyrolysis reaction with the high-efficiency catalyst.

→ The pyrolyst oil gas is turned into high quality fuel oil and small amount of combustible gas after following processes such as fractional distillation separation, fixed bed secondary gas catalyzing and de-waxing etc.

→ The combustible gas is totally used as fuel to the system after scrubbing, which achieves heat energy self-supporting. The gas after being burnt will be qualified discharged after gas purification process.

→ The small amount of solid residue generated from the reaction is continuously discharged out of the reactor, and that could be further processed into fuel stick.

Oil Yield rate from waste plastic:

PVC material with very little oil, not good

PE 95%

PP 90%

PS 90%

ABS 40%

Pure white plastic cloth 70%

Plastic package 40%

Plastic logo 20%

Paper coating dry material 60%, wet 15%-20%

Household garbage 30% - 50%

Pure plastic cable covers 80%

Clean plastic bag more than 50%