5th generation waste tire/plastic recycling machine

Waste plastic

With increasing plastic products consumption, waste plastic is also growing. At present in the world, waste plastic are mainly as plastic film, plastic yarn and fabric, foam, plastic packaging and containers, daily plastic products, plastic bags, agricultural film and so on. Besides, cars plastic, electronic and electrical appliances supporting plastic become one of the important sources of waste plastic after these products scrap. If there is any mistake of the application and post-processing of the storing, transportation and processing of waste plastic, it will damage the environment and harm to people’s health.

Waste tyre

With the development of society, our daily life is full of rubber products, such as tyre, shoes and so on. On one hand, they make our life convenient, on the other hand, if not be treated directly, continuous pyrolysis tire to fuel oil supplier, it devoted to meeting the demands of all the customers.

5th generation waste tire/plastic recycling machine

Waste tire/plastic recycling machine of henan doing mechanical equipment co.ltd is a new and green technology to convert the waste tIre/plastic to oil for fuel.

DOING is a professional manufacturer who producing waste tire/plastic recycling machine. As an outstanding supplier, DOING supply you waste tire/plastic recycling machine with high quality, competitive price and best after-sale service, which will makes you satisfied.

5th generation waste tire/plastic recycling machine technical data

| Technical parameter of 5th generation waste tire/plastic recycling machine | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tires/plastic | Waste tires/plastic | Waste tires/plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about 5th generation waste tire/plastic recycling machine | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

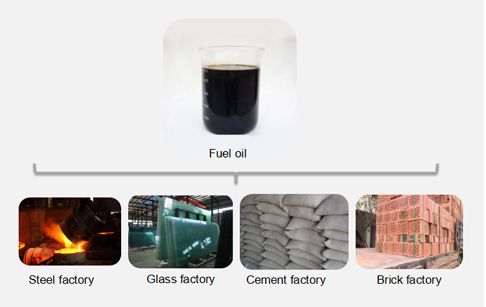

The final products and usage from waste tire/plastic recycling machine:

1. Fuel oil 45%-52%

Fuel oil application

A. power plant factory B. glass factor C. cement factory D. ceramic factory E. aluminum factory F. boiler factory G. central heating factory H. painting factory

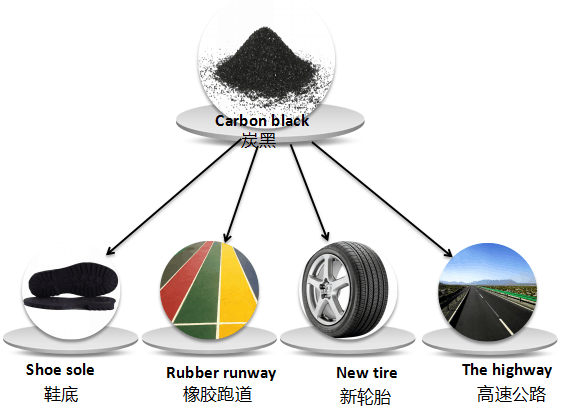

2. Carbon black 30%-35%

Carbon black application

Request Information

Send your inquiry for further information