Waste plastic and waste tyre pyrolysis plant

Waste plastic and waste tyre pyrolysis plant

What is pyrolysis:

Pyro = heat. Lysis = break down.

Pyrolysis is chemical reaction. This reaction involves molecular breakdown of larger molecules into smaller molecules in presence of heat. Pyrolysis is also known as thermal cracking, cracking, thermolysis, depolymerization, etc.

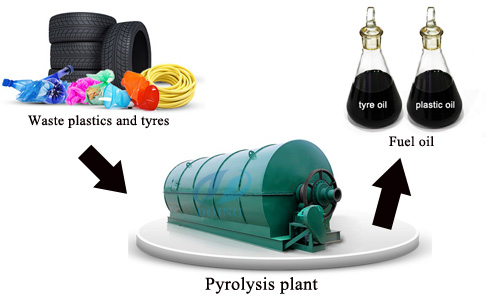

Tyre/plastic pyrolysis is: the process of converting waste tyres/plastic into industrial fuels like tyre/plastic pyrolysis Oil, Carbon Black, Steel Wire and Hydrocarbon Gas.

Waste plastic and waste tyre pyrolysis plant is an industry that converts waste plastic & tires & rubber and other waste materials into Pyrolysis Oil, Carbon Black & Hydrocarbon Gas. The Waste plastic and waste tyre pyrolysis plant can reduce the volumes of the waste products and help human protect the environment.

The main advatage of waste plastic and waste tyre pyrolysis plant is zero emission ,high efficiency .Waste plastic and waste tyre pyrolysis plant not only can solve the problem of waste tyre pollution ,but also can bring substantial benefits for you.

Waste plastic and waste tyre pyrolysis plant can process raw material

Pyro = heat. Lysis = break down.

Pyrolysis is chemical reaction. This reaction involves molecular breakdown of larger molecules into smaller molecules in presence of heat. Pyrolysis is also known as thermal cracking, cracking, thermolysis, depolymerization, etc.

Tyre/plastic pyrolysis is: the process of converting waste tyres/plastic into industrial fuels like tyre/plastic pyrolysis Oil, Carbon Black, Steel Wire and Hydrocarbon Gas.

Waste plastic and waste tyre pyrolysis plant is an industry that converts waste plastic & tires & rubber and other waste materials into Pyrolysis Oil, Carbon Black & Hydrocarbon Gas. The Waste plastic and waste tyre pyrolysis plant can reduce the volumes of the waste products and help human protect the environment.

The main advatage of waste plastic and waste tyre pyrolysis plant is zero emission ,high efficiency .Waste plastic and waste tyre pyrolysis plant not only can solve the problem of waste tyre pollution ,but also can bring substantial benefits for you.

Waste plastic and waste tyre pyrolysis plant can process raw material

Waste plastic and waste tyre pyrolysis plant can process raw material

1.Waste tire/tyre

2.Waste plastic

3.Wast rubber

Working process of waste plastic and waste tyre pyrolysis plant2.Waste plastic

3.Wast rubber

Working process of waste plastic and waste tyre pyrolysis plant

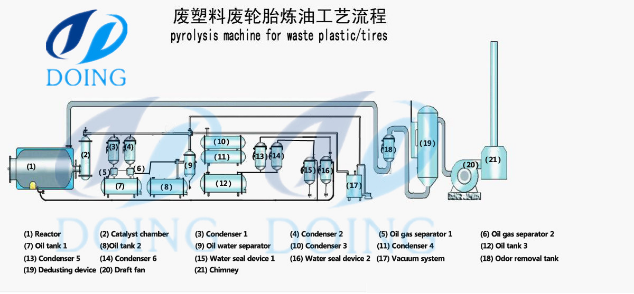

In the waste tyre pyrolysis process, the waste plastic/ tyres will firstly be put into the reactor.

Secondly, burn the fuel material (coal, wood, oil or natural gas) in the combustion system. The reactor will slowly heat, when the temperature reach around 120℃, it will produce oil gas.

Thirdly, oil gas will be processed and then go to cooling system to cold liquid oil. The gas which can not be liquid under normal pressure will go back to combustion system to replace the fuel material to burn the reactor.

Fourthly, after finished oil production, the temperature of reactor will be down and the carbon black will be discharged automatically. When the temperature fall to 100℃, workers could open the door of the reactor to discharge the rest steel wire.

Lastly, the released gas can achieve national emission standard through the dedusting system。

After the whole pyrolysis process of plastic/tyres is completed, the final products such as tyre/plastic pyrolysis oil, carbon black and steel wire can be sold directly or further processed into new products. Anyway, you will benefit a lot from them.

Waste plastic and waste tyre pyrolysis plant advandage

Firstly, it can protect the environment. It is equipped with the supporting facilities to make sure that the plant will not do harm to the environment.

Secondly, the emission can reach the national standard, because there is almost no pollution produced during the working process.

Thirdly, the quality of the tyre/plastic oil pyrolysis oil is high. The oil can be directly used as fuel, or you can reprocess it into diesel if you have the need.

Fourthly, the design of the plant is advanced. The designer takes many factors into consideration, and the plant is safe and easy to operate, because of the high degree of automatization and safety.

Last, it can also deal with the waste plastic, rubber, oil sludge and so on.

Although the plant is great, there are still many people failed when using the plant to get fuel oil.

Waste plastic and waste tyre pyrolysis plant profit analysis

Fuel oil from waste plastic and waste tyre pyrolysis plant

| Profit analysis from Mexico cutomer(10 tons capatity) | ||

| Cost for one batch | ||

| NO. | Item | Cost of each batch |

| 1 | 10 tons of waste tire | 10T*USD 42.5/t=USD 425 |

| 2 | 0.4 tons of coal | 0.4T*USD 70/t=USD 28 |

| 3 | Electricty and water | 244 kwh*USD0.26=USD 63.44 |

| 4 | Workers | 4*USD 15=USD 60 |

| 5 | Total cost | USD 576.44 |

| Income for one batch | ||

| 1 | Crude oil | 4.5T*USD960=USD 4320 |

| 2 | Steel wire | 10T*15%*USD350/T=USD 525 |

| 3 | Carbon black | 3T*USD 20/T=USD 60 |

| Total income | USD 4905 | |

| Profit | ||

| 1 | Daily profit | USD 4328.56 |

| 2 | Month profit | 4328.56*25 days=USD 108214 |

| 3 | Annual profit | USD 108214*10 months=USD 1082140 |

Waste plastic and waste tyre pyrolysis plantt technical data

| Technical parameter of Waste plastic and waste tyre pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyre,waste plastic | Waste tyre,waste plastic | Waste tyre,waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about Waste plastic and waste tyre pyrolysis plant | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

Waste plastic and waste tyre pyrolysis plant final product application

Fuel oil application

1. Fuel oil (45%-50%): Oil from waste plastic and waste tyre pyrolysis plant can be used as industrial fuel for burning.

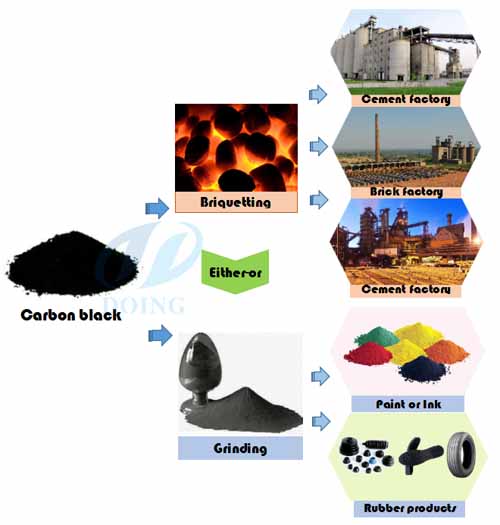

Carbon black application

2. Carbon black (30%): First, Carbon black from Waste plastic and waste tyre pyrolysis plant is carbon black. You can sell it to the brick factory as internal combustion or to the factory which need it as raw materials, such as shoe, tire, cable and sealant companies. Second, could make further process, make carbon black powder into carbon black briquette, and use it for burning.

3. Steel wire (10-15%): It can be sold to the iron and steel company directly.

4. Waste gas (5%): we have a special design could recycling it into fire furnace for burning.

3. Steel wire (10-15%): It can be sold to the iron and steel company directly.

4. Waste gas (5%): we have a special design could recycling it into fire furnace for burning.

Request Information

Send your inquiry for further information