Tire pyrolysis plant

Tire pyrolysis plant

The tire pyrolysis oil, one kind of end products extracted from the pyrolysis process, is often used for producing heat, electricity, steam and so on.

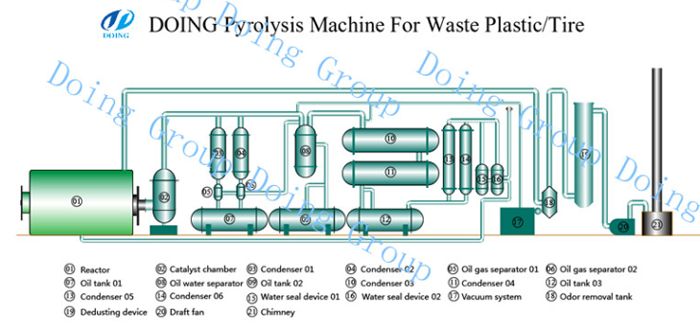

Tire pyrolysis plant working process

Tire pyrolysis plant working process

Firstly, make reactor rotate clockwise 0.4r/min, put raw material into reactor, close feeding door.Secondly, burned the fuel material(coal,or wood,or natural gas ,oil )in the furnace. Reactor will be slowly heated, when the temperature reach around 180 oC, oil gas will come out . then go to cooling system and liquid to oil.

Some incondensable gas which can't cooling down will be lead to furnace through a gas pipe. It will be used to heat reactor.

This can save your energy. Only the first 2 hours use energy for heating. After the first 2 hours mainly use gas, little energy is

ok. After pyrolysis, all the oil gas come out from reactor, the temperature will fall down. Then make it rotate anticlockwise, carbon black discharging begin. Lastly,when the temperature deduce to 50 oC, worker can opened the door of reactor take steel wire.

Tire pyrolysis plant advantage

Tire pyrolysis plant

1.100% recycling of tire wastage is achieved (No churn left after the process)

2.No chemical ingredients are used in process (environment friendly)

3.During and after the process; no soil, water or air pollution is observed.

4.Creates economically valuable products out of wastage tyres (These are an industrial product that have a good market value and demand)

5. The most cost-effective wastage tire recycling technology in the world.

6. Raw material (wastage tire) is cheap and easy to provide. These are the by-products of tyre production.

7.Each recycled ton of tires preserves 10 tons of CO2 that is a major green house gas.

Tire pyrolysis plant technical data

| Technical parameter of waste tire pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tire | Waste tire | Waste tire |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about waste tire pyrolysis plant | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

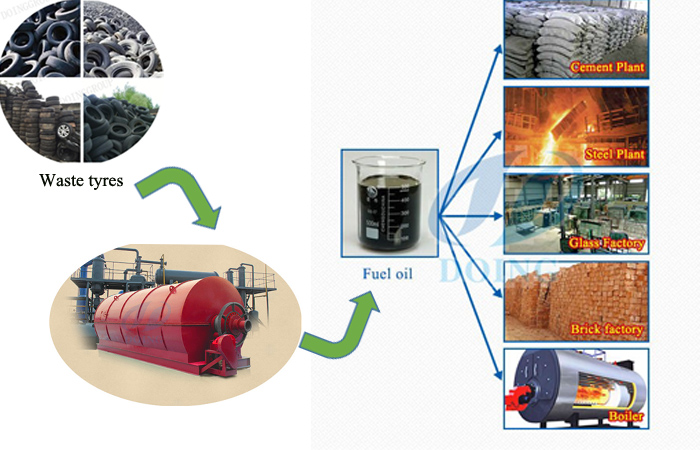

Tire pyrolysis plant final product application

Fuel oil application

Fuel oil from tire pyrolysis plant

A.power plant factory

B.glass factory

C.cement factory

C.cement factory

E.boiler factory

G.central heating factory

Carbon black from tire pyrolysis plant

Carbon black application

B.conveyor ban

C.hose and doormat

D.black nylon bag

E.rubber additive

F.automatic spare parts

G.heat isolation

Request Information

Send your inquiry for further information