Home > Product > Waste Tire Pyrolysis Plant>China environmental friendly pyrolysis plant manufacturer

Home > Product > Waste Tire Pyrolysis Plant>China environmental friendly pyrolysis plant manufacturer

China environmental friendly pyrolysis plant manufacturer

Traditional soil stove

Traditional soil stove not only severely damages the ecological environment, disturbs the market order, but also places serious safety hazards on the lives and property safety of the surrounding people. This issue has caused the public security law enforcement agencies in our country to attach great importance to this phenomenon.

Troditional soil stove is unlawful

At present, there are already many troditional soil stoves under the high pressure of the law enforcement agencies and they are subject to relevant legal sanctions.

Due to environmental issues, corresponding documents have been issued at this year's two important political sessions to emphasize the importance of environmental protection for the national economy and people's livelihood.

DoingGroup's pyrolysis plant

Under this situation, what kind of oil pyrolysis plant should we choose to comply with the development of national policies without affecting our normal equipment operation?

On the one hand,The DoingGroup's waste plastic/tire pyrolysis plant is much higher than the traditional soil stoves due to the tightness of the oil output. On the other hand, DoingGroup's waste plastic/tire pyrolysis plant is in the R&D design stage. Taking into account that the waste generated by combustion, waste water, and waste residue can cause pollution to the environment, its environmental protection from the following aspects.

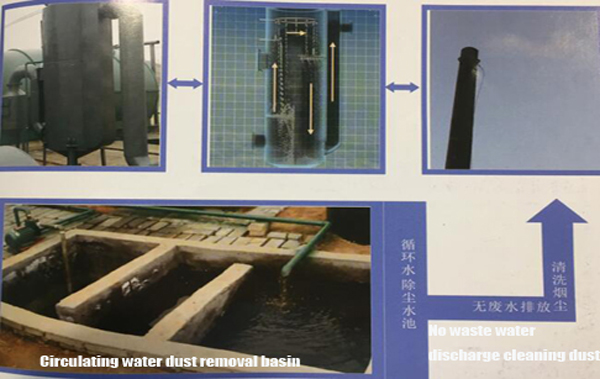

Wastewater pollution control

The company's waste tire pyrolysis plant production line, whether it is cooling water or dedusting water all use recycled water, to ensure that the production process to achieve zero discharge of wastewater.

(1) Cooling water

Column tube condenser design, the pipeline to go oil, pipe outside the water. Water and oil are in zero contact, and the cooling water can be recycled without emissions. Both environmental protection and increased cooling area, so that oil and gas can be fully cooled.

DoingGroup enviromental protection dedust waster system

(2) Dedusting water

The machine is equipped with a professional water film dust remover. Three-layer high-pressure spray technology can fully clean solid particles in smoke.

(3) High efficiency dry dedusting

If the fuel is coal, firewood or heavy oil, the amount of smoke is large, you can also choose to use pulse dust removal device. Dry dedusting does not require water and does not produce any water contamination.

Waste gas pollution control

The exhaust gas mainly comes from the exhaust gas generated during the oil pyrolysis plant production process. Under normal circumstances, the exhaust gas can be directly recycled to heat the tire pyrolysis reactor to save other fuels.

The smell of smelly chicken eggs produced in the exhaust gas will cause air pollution when discharged into the air, and the harmful gas to the human body will help the customer to completely solve the problem of factory odor by the company's desulfurization and deodorization tower system.Got the unanimous praise.

Waste residue pollution control

The carbon black residue generated during the combustion process is automatically discharged outside the furnace through the company's underground sealed slag discharge system. Due to better sealing, secondary pollution of the air caused by the waste residue during the discharge process can be avoided.

Responding to the national call to protect our enviromental, DoingGroup is your best choice ,investing in oil pyrolysis plant!

| Technical parameter of DoingGroup pyrolsysi plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyres | Waste tyres | Waste tyres |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about DoignGroup pyrolysis plant | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

China environmental friendly pyrolysis plant manufacturer plant final product application

Fuel Oil (40% to 45%)

Fuel oil application

The main oil product produced by our recycling application is the fuel oil that is wide used for industrial and commercial purposes. The oil has 40% to 45% of the amount of recycled scrap tyres, which will be carried with licensed tanker trucks.

Carbon Black Powder (30% to 35%)

Carbon black application

Steel Wire Scrape ( 10% TO 15% )

The third product of waste tyre pyrolysis process plant is steel wire, the quantity of steel wire is about 10% to 15% according to tyre quality. Its very easy to sales steel wire scrape in local market.

Pyrolytic Gases ( About 10 % )

We get pyrolytic gases during process about 10% of waste tyre. The main component of this gases are methane ( CH4 ), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

Request Information

Send your inquiry for further information