Tire doubling and tripling packing machine

If you have collected some quality car tires and want to transport them, what can you do with them to maximize your profits? We suggest that you can purchase a tire doubling and tripling packing machine. Tire doubling and tripling packing machine can set 3-4 tires together, which is commonly used by tire workshops or used tire dealers or collectors. It can be used to double pack scrap tires for easy storage and transportation.

Tire doubling and tripling packing machine operation

Advantages of Tire Doubling and Tripling Machine

▶ The major advantage of the tire doubling and tripling packing machine over the traditional manual tire doubling and tripling packing machine that uses physical force is that it is simpler and easier to operate for using electricity.

▶ It is driven by a motor with compressed air, so there is no risk of electric shock.

▶ It can solve the problem of immature manual technology of workers, which affects quality and output, and can save labor and increase output at the same time.

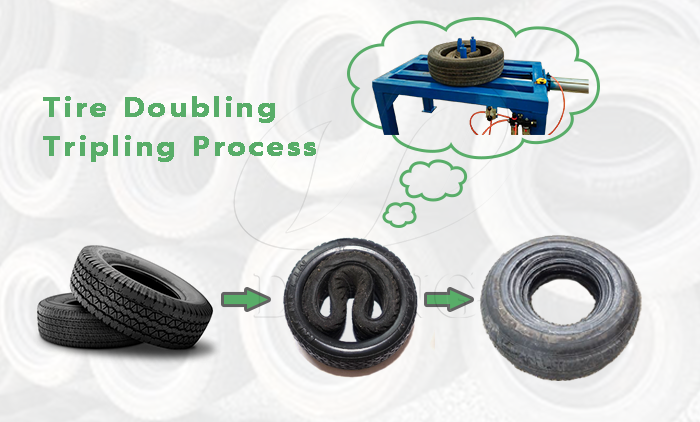

Tire doubling process

Tire doubling process

▶ It is small and lightweight, thus can be easily moved from one place to another.

▶ Doing tire doubling and tripling packing machine also has a reverse unpacking feature. This machine can also be used to separate tires when you are transporting packed tires to another location and want to unpack them.

Technical Parameters of Tire Doubling and Tripling Packing Machine:

| No. | Items | Contents |

| 1 | Machine | Tire doubling and tripling packing machine |

| 2 | Function | Make several tires nested together with reversible unpacking function |

| 3 | Advantage | Make room for the storage and transportation of used tires |

| 4 | Length | 1.50m |

| 5 | Width | 0.85m |

| 6 | Height | 1.12m |

| 7 | Weight | 200kg |

| 8 | Power | Compressed air with a small amount of electricity |

| 9 | Pressure | 6kg/ 6bar/ 0.6Mpa |

Tire doubling and tripling packing machine can be used in different scenarios depending on the customer's needs.

• For some tire dealers

They want to keep complete tires for further use. So they don't want to cut tires for better storing and transport, then they can use tire doubling and tripling packing machine to make several tires nested together firstly. After transport, they can unpack the tires to normal for further use.

• For some tire pyrolysis plants

During the operation of tire pyrolysis plants, operators hope to fill as many tires as possible inside the pyrolysis reactor to convert more tires into fuel oil with less time. But as we all know that tires contain steel wire which is difficult to press. This time you will need to use a tire cutter to cut tires into small pieces. But after cutting, the steel wire inside tires will become small pieces mix with carbon black after pyrolysis process, which is difficult to separate. Therefore, you can use tire doubling and tripling packing machine to make several complete tires together, then put them into the reactor. It can not only save the room, the steel wire inside tires also can keep complete. After pyrolysis, the big steel wire can tangling together, which is easy to pull out by a hook.

Our Doing tire doubling and tripling machines have been currently exported to the United States, Canada, Australia, Japan, and other countries. After being processed by the tire doubling and tripling packing machine, customers' tires are exported to Africa and other countries for profit.

We highly recommend tire doubling and tripling packing machine to anyone who wants to save space to store or transport scrap or used tires or to be used in the tire pyrolysis business. If you want to start a tire doubling and tripling business, please contact us for more information.

Request Information

Send your inquiry for further information