Home > News > Industry News>Acid-alkali washing technology for refining waste engine oil into diesel

Home > News > Industry News>Acid-alkali washing technology for refining waste engine oil into diesel

Acid-alkali washing technology for refining waste engine oil into diesel

Industry News / Date:March 2, 2024

Waste engine oil is usually mixed with impurities such as moisture, dust, other miscellaneous oils, and metal powder produced by machine parts wear, causing its color to turn black, its viscosity to increase, and even deterioration. But with acid and alkali technology, we can refine waste engine oil into diesel by waste oil distillation plant.

The process flow of acid and alkali washing of waste engine oil to refine diesel is as follows:

Open the thermal oil furnace and pour the thermal oil into the high tank. The thermal oil flows into the low tank by its own gravity. Open the valve and pump the thermal oil into the distillation reactor and decolorization system of waste oil distillation plant in advance for subsequent use.

The waste engine oil is transported to the distillation reactor through the oil pump, and the indirect heating system is turned on for high-temperature distillation. After the distillation reactor reaches a certain temperature, a large amount of oil gas will be evaporated.

Waste oil distillation plant heating

Waste oil distillation plant heating

The oil gas will first pass through a safety device-the gas distribution bag to prevent excessive gas from causing blockage and affecting the condensation effect and safety. Then it will enter the vertical condenser and horizontal condenser to be fully cooled into oil. The cooled liquid oil will enter the oil tank for temporary storage.

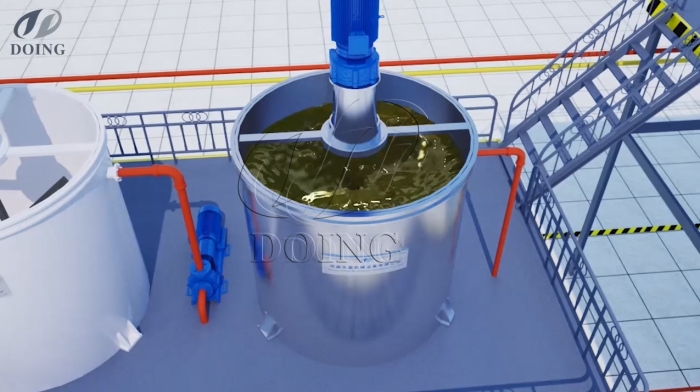

The cooled oil is first pumped into the pickling tank through the oil pump, and a certain proportion of acidic solution is added and stirred to remove the wax and sulfur in the liquid oil; then, the acidified oil enters the alkali washing tank, and a certain proportion of acid solution is added. The alkaline solution is stirred for 3-4 hours and then precipitated for 30 minutes. This process can neutralize the acid in the waste engine oil and turn it into a neutral substance.

Waste oil acid-alkali washing to diesel distillation process

Waste oil acid-alkali washing to diesel distillation process

It should be noted that the process of adding acid and alkali solutions requires workers to operate. Regarding the specific solutions and proportions added to the waste oil distillation plant, please consult the professional business team of Henan Doing Company.

There are still some impurities and pigments in the crude oil after acid and alkali washing, which need to be decolorized. Pour the crude oil into the decolorization tank, then add white clay and stir thoroughly, using the adsorption effect of the white clay to remove pigments and other impurities in the crude oil; pump the oil mixed with the white clay into a plate and frame filter to filter out the waste clay , the crude oil then enters the bag filter for fine filtration, and then clean, bright-colored non-standard diesel can be obtained.

Open the slag discharge port, and the remaining asphalt in the waste oil distillation plant reactor will naturally fall due to its own weight and flow directly to the bottom for discharge.

Part of the non-condensable gas generated during the high-temperature distillation process is processed by the tail gas purification system and returned to the distillation reactor as fuel for heating, saving fuel; the flue gas generated during the distillation process and tail gas combustion process can be purified by the desulfurization tower. Discharge.

Usages of diesel made from waste oil distillation plant

Usages of diesel made from waste oil distillation plant

All above is the introduction of acid-alkali washing technology for refining waste engine oil to diesel. The obtained diesel extracted from waste oil distillation plant can be directly used in boilers, heavy machinery, agricultural machinery, engineering machinery, ship engines, diesel burners, etc. to achieve waste reuse. In addition, after acid-alkali washing and refining of waste engine oil, 10-13% asphalt and 5% combustible gas can be obtained, and the product utilization rate is high.

Request Information

Send your inquiry for further information