Home > News > Industry News>What kind of rubber materials can be recycled into fuel by pyrolysis plant?

Home > News > Industry News>What kind of rubber materials can be recycled into fuel by pyrolysis plant?

What kind of rubber materials can be recycled into fuel by pyrolysis plant?

Industry News / Date:November 21, 2023

As is all known, rubber material, like black pollution, has been plaguing governments and people of various countries. Many countries are studying how to deal with rubber waste in an environmentally friendly way. There is a good technology---- pyrolysis, which can recycle waste rubber materials into fuel oil.

Pyrolysis plants can convert a variety of rubber materials into fuel, including waste truck/car/bicycle tires, OTR tires, rubber powder, rubber cable sheath, rubber soles, rubber belts, rubber gaskets and seals, rubber mats, rubber hoses, rubber offcuts and scraps, rubber conveyor belts, unclassified rubbers, etc.

Waste rubber materials for pyrolysis into fuel oil

Waste rubber materials for pyrolysis into fuel oil

These rubber materials are mainly composed of rubber and carbon, which can be effectively converted into fuel oil, charcoal, and gas by the pyrolysis process. Generally speaking, the rubber pyrolysis oil yields are between 30% to 50%. But the composition and quality of the rubber materials can vary, which can affect the yield and quality of the resulting products. Additionally, some rubber materials may require pre-processing or shredding before being fed into the pyrolysis plant.

Then is it profitable to invest in a waste rubber recycling pyrolysis plant? I want to say yes, it's not only profitable, but also environmentally friendly.

Waste rubber recycling pyrolysis plant can efficiently convert waste into energy, the final products all have wide applications.

Rubber recycling pyrolysis plant final product applications

Rubber recycling pyrolysis plant final product applications

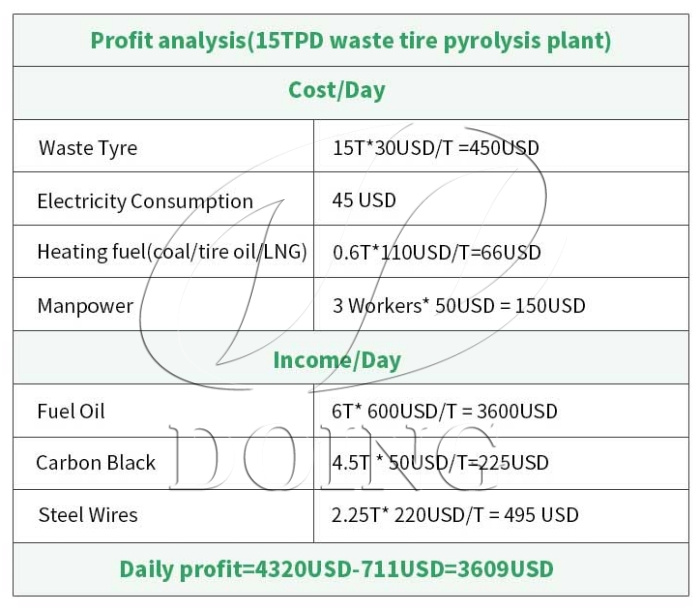

The fuel oil is a high calorific value alternative heating fuel which can widely used in furnaces, boilers, heavy oil power plants, heavy industries like steel plants, brick plants, glass plants, cement plants, etc. And it can also be refined by waste oil distillation plant into non-standard diesel used in tractors, ships, boats, trucks, etc. The carbon black which is also useful and could be reused, and exhaust gas which will be used to heat the waste rubber recycling pyrolysis plant itself to save investment cost. Based on our customers' feedback, the daily a set of 15TPD rubber tire pyrolysis plant may reach 3609USD.

15TPD rubber tire pyrolysis plant profit analysis

15TPD rubber tire pyrolysis plant profit analysis

It should be noted that the use of rubber pyrolysis technology requires professional technical support and equipment to ensure safe and efficient use. In addition, the use of pyrolysis technology may also require relevant permits and certificates to comply with relevant laws and regulations. Therefore, it is recommended to seek professional advice before using pyrolysis technology.

If you are interested in the waste rubber recycling pyrolysis plant, please feel free to contact the DOING group. We can offer the best rubber pyrolysis solution based on 13+ years experience of pyrolysis plant fabrication and installation.

Request Information

Send your inquiry for further information