How do waste tires plastic pyrolysis plants prevent explosions?

Industry News / Date:November 10, 2022

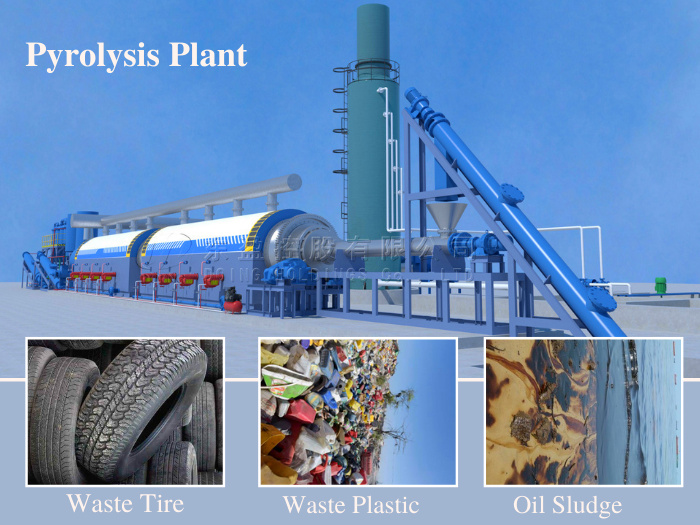

In the operation process of waste tires plastics pyrolysis plant, safety is the top priority. Waste tires plastic pyrolysis plants should be equipped with complete safety devices to avoid explosions and other production accidents.

Pyrolysis plant

Pyrolysis plant

Taking the pyrolysis plant designed, developed and produced by Henan Doing Company as an example, we have designed the following aspects of safety measures to prevent equipment explosions:

1. Both ends of the pyrolysis plant reactor adopt the design of arc pressure vessel head welding, one-piece pressing, which is high temperature and high pressure resistance, and not easy to break. Even if an emergency occurs, when the pressure in the furnace is abnormally higher than normal pressure, it can be ensured that the fault can be eliminated in a safe situation. The pressure-resistant welding design of the arc head can maximize the safety factor.

The reactor adopt the design of arc pressure vessel head welding

The reactor adopt the design of arc pressure vessel head welding

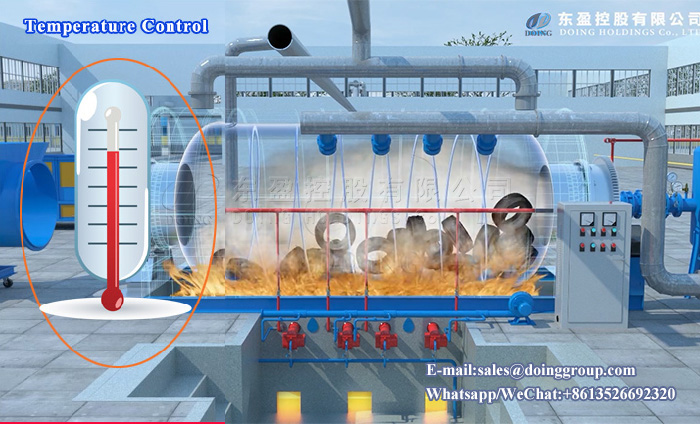

2. The air outlet of the main furnace of the waste tire plastic pyrolysis plant is equipped with temperature gauges and electric pressure gauges. The temperature can be transmitted to the console in real time. By observing the temperature display, it is convenient to adjust the firepower during the heating process and avoid the situation that the temperature in the furnace is too high. And there is an alarm bell connected to the electric pressure meter. When the pressure in the furnace is abnormal, the on-site alarm bell will alarm in time, reminding the on-site operators to troubleshot in time.

Temperature control system

Temperature control system

3. The furnace door and the air outlet of DOING pyrolysis plants are equipped with manual and automatic pressure relief valves respectively. When the pressure in the main furnace is abnormal, the workers can release the pressure by opening the manual pressure relief valve on the furnace door after the alarm bell. And when the pressure in the furnace reaches a certain value, the automatic pressure relief valve will start to work in time to achieve the purpose of automatic pressure relief to eliminate the excessive pressure in the furnace.

The worker is debugging the machine

The worker is debugging the machine

In addition to the above points, it should be noted that workers operating waste tire plastic pyrolysis plants must undergo professional training. In many cases, some details in the operation process are wrong, which will lead to damage or even explosion of the equipment. To this end, Henan Doing provides customers with equipment operation manuals, and arranges professional engineers to do door-to-door training to guide customers in operation.

Request Information

Send your inquiry for further information