How to choose a good waste tire/plastic pyrolysis plant?

Industry News / Date:November 13, 2018

At present, there are different waste tire/plastic pyrolysis plant manufacturers on the market, but whether the quality of the waste tire/plastic pyrolysis plant produced is good or not and if its service life is up to standard or not, you should have no much idea if you didn’t do any research about the waste tire/plastic pyrolysis plant. As we all know that the quality and usage life of the waste tire/plastic pyrolysis plant determine whether it’s cost-effective or not. In addition, except the quality and usage life, it should also be noticed if the waste tire/plastic pyrolysis plant is not environmental friendly or not. Does the waste tire/plastic pyrolysis plant has black smoke? Does the waste tire/plastic pyrolysis plant generate waste water? Does the waste tire/plastic pyrolysis plant produce bad smell? Etc. These are all important factors when you trying to choose a good waste tire/plastic pyrolysis plant. Here we have some references for you if you’re now considering to buy a good waste tire/plastic pyrolysis plant. Hope these suggestions would provide some help to you.

Waste tire/plastic pyrolysis plant

Waste tire/plastic pyrolysis plant

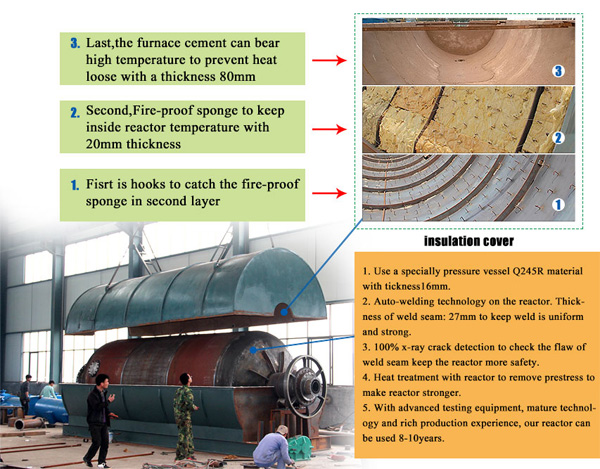

1. Choose a good quality pyrolysis reactor

Pyrolysis reactor is the main part of a waste tire/plastic pyrolysis plant. So the quality of the pyrolysis reactor directly decide the usage life of the waste tire/plastic pyrolysis plant, And the material, the thickness and the welding of the pyrolysis reactor decide the quality of the pyrolysis reactor is good or not. We DOING Company adopts 16mm Q245R boiler plate to produce the pyrolysis reactor. The Q245R boiler plate could make sure the pyrolysis reactor could bear the required high temperature heating. And 16mm thickness of the pyrolysis reactor plate is the best choice by considering about the heat transfer factor. Also our pyrolysis reactor is welded by auto-welding technology with three-step welding to make sure the welding of the pyrolysis reactor is perfect, thus to avoid the crack during long time high temperature operation.

Waste tire/ plastic pyrolysis reactor

Waste tire/ plastic pyrolysis reactor

2. Choose an environment friendly waste tire/plastic pyrolysis plant

The main reason why developed the waste tire/plastic pyrolysis plant is mainly to solve the waste tire and plastic pollution, which are already widely known as “black pollution” and “white pollution”. So to avoid the secondary pollution caused by the waste tire/plastic pyrolysis plant is super important. But there are some badly designed waste tire/plastic pyrolysis plants should not care much about the environment, they only care about profit. Who are using the bad designed waste tire/plastic pyrolysis plants, are deeply troubled by the black smoke, bad smell and carbon black dust everywhere. In view of this, DOING Company determined to manufacture the environment friendly waste tire/plastic pyrolysis plant from the beginning, and insist to the end. In our design of the waste tire/plastic pyrolysis plant, we have the smoke cleaning system, the tail gas cleaning system, the bad smell removal system, the sealed carbon black discharge system, etc. All the designs could ensure your operation of the waste tire/plastic pyrolysis plant is under a clean environment, and make sure you would not be troubled or complained by local authorities.

Waste tire/plastic pyrolysis plant environmental protection system

Waste tire/plastic pyrolysis plant environmental protection system

3. Choose a waste tire/plastic pyrolysis plant with safety guarantee

When we start to do a new business, the main purpose is to get profit without doubt. But there is one thing is much more important than profit, it’s safety. No matter what business we do, what plant we operate, safety the always the priority. Without safety, what’s your meaning to do the business, to earn the profit. So when you’re choosing to buy a waste tire/plastic pyrolysis plant, safety control should be also the first thing to pay attention to. We had heard many times that the waste tire/plastic pyrolysis plant cracked, exploded or fired during operation in China, in India, in Bangladesh, in South America, etc. Many workers lost their lives in the accidents unnecessarily. So how can we avoid those safety problems happened? Let us give you some reference. If you check the waste tire/plastic pyrolysis plant manufactured and supplied by DOING, you will find the plant is equipped with oil-water separator, the water seal, the vacuum device, the interlocking system of pressure overhigh-alarm ring-safety valve auto open, etc. Oil-water separator is an anti-back device, which could prevent the oil gas flow back to cause high pressure. Water seal is also an anti-back device, but for preventing tail gas (uncondensable gas) flow back to cause high pressure. Vacuum device could ensure the normal operation pressure of the whole system. The interlocking system of pressure overhigh-alarm ring-safety valve auto open could make sure when system pressure of the waste tire/plastic pyrolysis plant suddenly rise high, it could have automatic pressure discharge. A good quality machine with all of the safety devices would be the best safety guarantee for you.

Waste tire/plastic pyrolysis plant safety system

Waste tire/plastic pyrolysis plant safety system

4. Choose a professional supplier with an experienced installation team

As one industry become more and more popular and profitable, there would be more and more disrelated factories or trading companies step into this field and act as the supplier of the waste tire/plastic pyrolysis plant. But so many waste tire/plastic pyrolysis plants were sold without after-sale service, which caused big troubles to the buyers. As we all know that waste tire/plastic pyrolysis plant is not like a small product or common used daily supplies, without the professional instruction or guidance and training, it’s very hard for anyone to install and operate the waste tire/plastic pyrolysis plant well. So before you choose to buy the waste tire/plastic pyrolysis plant, better at first to make sure the supplier is professional with an experienced installation team, which could give you a worriless after-sale service after you spent the money on the machine.

DOING factory

DOING factory

Henan DOING Mechanical Equipment Co., Ltd located in central plains region of China where is the manufacturing base of heavy machinery. As one manufacturer and supplier of the heavy machinery, we DOING Company have been specialized in waste tire/plastic pyrolysis plant for 8 years, with 85 staff in office, 35 workers in factory, among those, we have the professional R&D and design team, manufacturing team, website building team, website maintenance team, sales team, after-sales team and installation team with customized service. We believe that what we have is what you want. Welcome your contact and visit at any time!

Request Information

Send your inquiry for further information